At #61DAC it was quite clear that semiconductors have “grown up”. The technology has taken its place in the world as a mission-critical enabler for a growing list of industries and applications. Reliability and stability become very important as this change progresses. An error of failure is somewhere between inconvenient and life-threatening. The field of automotive electronics is a great example of this metamorphosis. We’ve all heard about functional safety standards such as ISO26262, but how do we make sure these demanding specs are always met? proteanTecs is a company offering a unique technology that provides a solution to these growing safety demands. During DAC 2024, you could see product demos showcasing automotive predictive and prescriptive maintenance. Read on to learn how proteanTecs introduces a safety monitoring solution.

Making the Roads Safer

proteanTecs defines a category on SemiWiki called Analytics. The company was founded with a mission to give electronics the ability to report on its own health and performance. It brings together a team of multidisciplinary experts in the fields of chip design, machine learning and analytics software with the goal of monitoring the health and performance of chips, from design to field. Its products include embedded monitoring IP and a sophisticated array of software, both embedded on chip and in the cloud. All this technology works together to monitor the overall operating environment of the chip to ensure top performance and to spot or predict problems before they become showstoppers.

News from the Show Floor

At the show, I was fortunate to have the opportunity to meet with Uzi Baruch, Chief Strategy Officer and Noam Brousard, VP of Solutions Engineering. It was a memorable and far-reaching discussion of the contributions proteanTecs is making to facilitate continued scaling for the electronics industry.

One comes to expect polished presentations at a show like #61DAC and indeed that was part of the meeting. I was also treated to a very entertaining and informative video; a link is coming. But perhaps the most impressive part was the live demonstration of the company’s technology. This is a brave move for any company at a major trade show. The solid performance of the demo spoke volumes about the reliability of the technology. Let’s look at some of the details.

proteanTecs RTSM™ (Real Time Safety Monitoring) offers a new approach to safety monitoring for predictive and prescriptive maintenance of automotive electronics. The application monitors the timing margin of millions of real paths of the chip with very high coverage in real-time, under real workloads, to alert the system before the lowest point that still allows error-free reaction. More details of this approach are shown in the figure below.

There are many aspects of system operation that must be monitored and analyzed to achieve the required balance for system reliability and performance. A combination of embedded sensors, sophisticated software and AI make it all work. The following list will give you a feeling for the completeness of the solution:

- Monitor non-stop: Remains always-on and monitors in-mission mode

- Assess issue severity: A performance index for risk severity grading

- Detect logical failures: Monitor margins with critical protection threshold

- Boost reaction time: Low latency of the warning signals

- Prevent fatal errors: A prescriptive approach for avoiding failures

- Customizable outputs: Configure multiple output interfaces to fine-tune desired dynamic adjustment

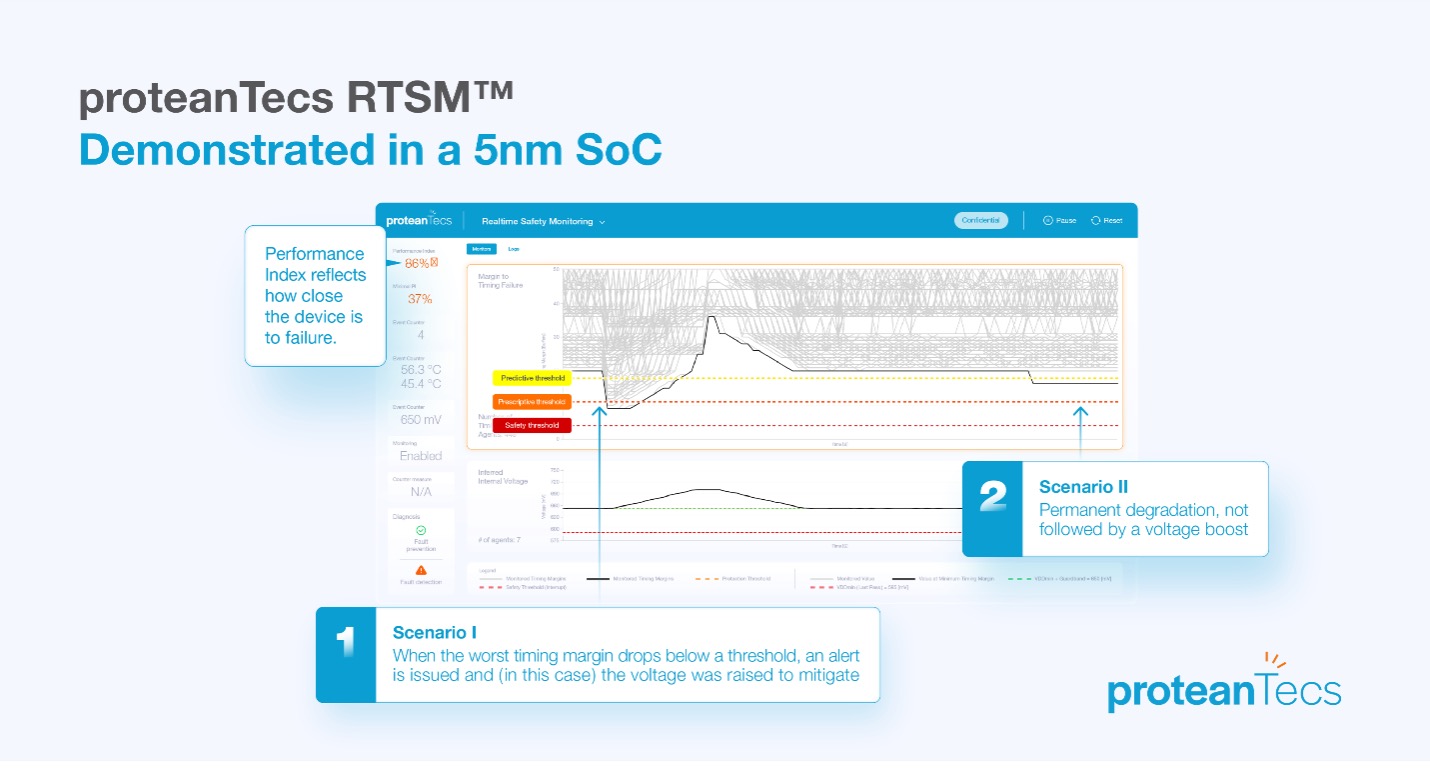

An example of this operation is shown in the figure below. RTSM outputs a Performance Index, as well as a notification targeting the device’s power/clock frequency management units. The Performance Index indicates how close the device is to failure (predictive). The warning notification helps adapt the voltage or frequency to overcome the risk of incoming failure (prescriptive). Similarly, as with any other request or input for dynamic power/clock frequency management, the RTSM output is customized to the specific system interfaces.

To Learn More

I have only scratched the surface of the capabilities offered by proteanTecs. If a closed-loop predictive and prescriptive system sounds like an important addition to your next design, you need to get to know these folks. You can start with that short, entertaining and informative video here.

There is also a comprehensive white paper available. Highlights of this piece include:

- The limitations of conventional safety assurance techniques

- RTSM’s algorithm-based Performance Index for assessing the issue severity

- Why monitoring margins under real workloads is crucial for fault detection

- The technology behind RTSM which allows it to monitor in mission-mode

- The role of RTSM in introducing Predictive and Prescriptive Maintenance

You can get your copy of the white paper here. And that’s how proteanTecs introduces a safety monitoring solution at #61DAC.

Also Read:

proteanTecs at the 2024 Design Automation Conference

Managing Power at Datacenter Scale

proteanTecs Addresses Growing Power Consumption Challenge with New Power Reduction Solution

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.