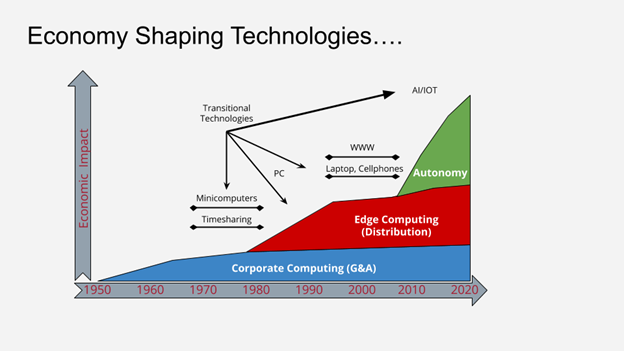

Electronics design mega-trends have been a transformational force for the world. As shown in blue in Figure 1, the first wave of electronics consisted of centralized computing and the leaders in the field included companies such as IBM, Digital Equipment Corporation (DEC), Wang, and others. Fundamentally, these technologies provided productivity solutions for the administrative (G&A) functions for the global business enterprise. With this shift, the finance, human resources, and administrative functions of global business were disruptively impacted. Gone were the days of a sea of admins doing paperwork.

Electronic Design Automation was born inside the large companies such as DEC as well as flagship university institutions such as UC Berkeley before spinning out into an independent industry. Initially, EDA for system design (PCB) and semiconductor design were of similar size. However, as Moore’s law drove increasing functionality onto a semiconductor chip, EDA tools for semiconductor design scaled accordingly. Over the last 50 years, semiconductor design has grown to dominate the business of EDA.

The next wave consisted of edge computing devices (red in Figure 1) such as personal computers, cell phones, and tablets. With this capability, companies such as Apple, Amazon, Facebook, Google, and others could add enormous productivity to the advertising and distribution functions for global business. Suddenly, one could directly reach any customer anywhere in the world. This mega-trend has fundamentally disrupted markets such as education (online), retail (ecommerce), entertainment (streaming), commercial real estate (virtualization), health (telemedicine), and more. In terms of design, the big shift was the focus on mobile battery based devices in highly integrated cost-sensitive products. To support this new system paradigm, the EDA design chain had to be updated to understand and support a wide variety of methods which minimized power dissipation. In addition, supporting integrated mechanical, packaging, system design became a necessity.

What is the next mega-trend and what does it imply for the required evolution of EDA capability ?

Today, we are at the beginning of the next major disruptive cycle caused by electronics. This cycle consists of embedded sensory devices (sometimes known as Internet of Things), local intelligence systems (sometimes known as machine learning), and global intelligence (sometimes known as cloud resources). Broadly called AI/IoT, these three technologies will disruptively impact nearly every market segment where in-field sensing with computing can solve interesting problems. Medical devices, mining, agriculture (land or ocean), space operations, and of course autonomous vehicles, are rich examples of this paradigm.

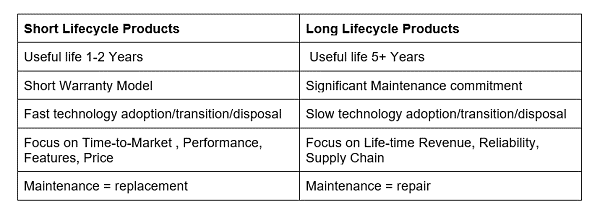

AI/IOT moves electronics onto the “edge” and also into the world of Long LifeCycle (LLC) products. Table 1 contrasts the system level characteristics between short and long cycle products. Similar to the shifts in previous mega-trends, the AI/IOT paradigm requires EDA to support several new capabilities. These include:

- Design for Supply Chain Resilience: Today, the semiconductor supply chain is dominated by SLC products, and this is not expected to change. LLC products face a circumstance where they need to design in such a manner as to absorb the enormous churn created by the SLC products on the semiconductor supply chain.

- Design for Reliability: Today, most of the semiconductor supply chain is optimized for the consumer life cycles. To gain the required reliability characteristics for long cycle products one must build the reliability through system design techniques.

- Design for Functional Evolution: Many LLC products are embedded in the field with high replacement costs (ex.. smart buildings). The probability for requirements evolution over time is very high, so designing for functional evolution is another key requirement of this product segment.

- Design for System Maintainability: Field maintainability is a key issue for LLC products. Thus, key ideas such as automatic calibration of sensors or automated detection of fault becomes very important in this design space.

Many of these issues have existed for many years in markets such as satellites and indeed agencies such as NASA have invested in internal solutions. However, similar to spinout from large information technology OEMs from the 1980s, there is a need for commercial EDA solutions to support the LLC design paradigms.

For those interested in further reading on these topics:

- Let’s Define Long Lifecycle (LLC) Electronics Markets

- LLC Markets and the Electronics Supply Chain

- LLC Markets and the AI/IOT Mega Trend

- Obsolescence Insurance, a New High-Margin Business for EMS Companies

- LLC Markets, the PCB ASIC Model and EMS

- Reconfigurable Computing and LLC Markets

Also Read:

The Growing Chasm in Electronic System Design

The Increasing Gaps in PLM Systems with Handling Electronics

The Increasing Gap between Semiconductor Companies and their Customers

Share this post via:

Flynn Was Right: How a 2003 Warning Foretold Today’s Architectural Pivot