Scott Seaton is the new CEO of Oasys Design Systems. Paul van Besouw, the CEO since the company’s founding, becomes the CTO. I met Scott last year when I was doing some consulting work for Carbon Design where he was VP of sales (the new VP sales at Carbon is Hal Conklin, by the way).

Scott Seaton is the new CEO of Oasys Design Systems. Paul van Besouw, the CEO since the company’s founding, becomes the CTO. I met Scott last year when I was doing some consulting work for Carbon Design where he was VP of sales (the new VP sales at Carbon is Hal Conklin, by the way).

I talked to Scott about why he had joined Oasys. After all, when you take on a CEO (or any senior position) in an early-stage company, the most important thing is whether you think that the company is going to be successful.

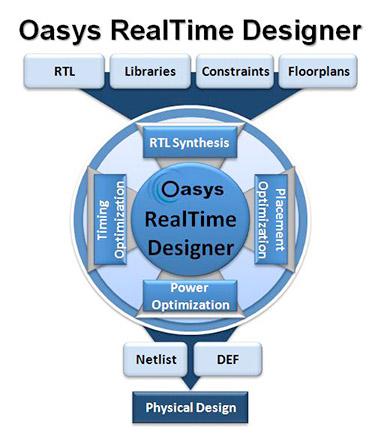

He believes that in RealTime Designer and RealTime Explorer that Oasys has breakthrough technology. When he talks to customers, they tell him that they have reduced their time to market by an average of 2 months compared to their previous methodology.

RTL designers need to get physical feedback. If they don’t use RealTime then the only way to do this is using the full implementation flow that typically takes 2-3 days. Oasys is at least 10 times faster than this. Further, since there is a single tool with a unified database, it is easy to highlight problems (such as timing constraint violations) and tie them back to the correct line of RTL. One customer told Scott that the last timing problem they tried to correct took them 6 hours just to find the correct bit of RTL. Cross-probing in RealTime takes a minute.

Oasys recently introduced RealTime Explorer to address this issue whereby RTL designers either don’t get any physical feedback (in which case their timing numbers are pretty much meaningless) or where it is extremely cumbersome to get the data. This is especially critical with geographically remote RTL development groups who may not have any access to the physical tools or, indeed, the expertise to run them if they did. Up to now, other vendors have offered either estimation tools or else taken synthesis engines and de-tuned them to gain speed while sacrificing quality-of-results (QoR) and thus correlation. Customers tell Scott that neither of these approaches address their needs. By definition, RTL engineers that are trying to push the boundaries of performance don’t have much margin for error. And in advanced nodes like 28nm, everyone is trying to push the boundaries of performance otherwise why bother.

Ultimately, none of this matters unless the customers are deriving real value. On every metric, Oasys is gaining momentum. Sales were up in 2012 by 114% over 2011 and they finished off in Q4 being cash-flow positive. Customers include 5 of the top 10 semiconductor companies, many using RealTime for 28nm tapeouts and some qualifying RealTime for production use at 20nm and 14nm nodes. All of them want to use RealTime for both RTL exploration and for implementation.

Share this post via:

TSMC vs Intel Foundry vs Samsung Foundry 2026