In 2003 Mentor acquired a company doing wiring harness design. Being a semiconductor guy this wasn’t an area I’d had much to do with. But more than most semiconductor people I expect.

In 2003 Mentor acquired a company doing wiring harness design. Being a semiconductor guy this wasn’t an area I’d had much to do with. But more than most semiconductor people I expect.

But back when I was an undergraduate, I had worked as a programmer for a subsidiary of Philips called Unicam that made a huge range of spectrometers and similar equipment for chemical analysis. These contained a brass cam, hence the name, that moved all the optics that had to be carefully machined. So carefully that the cam cutting lathes were in a temperature controlled room.

Each of these machines also contained a complicated wiring harness to hook up the electronics and the front panel and so on. The production volumes of spectrometers did not justify automating the manufacture of the harnesses. They were assembled by hand by a room full of women seated in front of drawing boards. On each drawing board was a carefully drawn full-scale diagram of the harness with pins to bend the wires around. When a harness was complete, someone would check it, and then the harness would be wrapped with cable-ties and sent off to be put into a spectrometer as it was assembled. The design was clearly done on the drawing boards by draftsmen by hand.

Then when I was at VaST I got involved in many meetings with automotive manufacturers. There is a wiring harness in each car. One of the reasons that automotive was increasingly interested in in-car networks such as CAN bus (unfortunately the C stands for ‘controller’ but ‘car area network’ seemed a better name) was that the wiring harnesses were starting to be embarrassingly large. They might weigh over 50kg, which affected mileage, and they had got so thick it was a real problem to find enough space to thread them through the car to get to the engine compartment, the dashboard, the rear lights and all the other places they needed to go. They were also incredibly complex to design. The wiring in the Airbus 380 caused major delays in the program; I hate to think how complex that wiring must be.

Wally Rhines told me once that the wiring harness products were a surprisingly fast growing business as they got more and more complex. Of course when you are used to putting a few billion wires on a chip, putting together a wiring harness seems almost primitive by comparison. Anyway, I decided to find out more and to watch Mentor’s webinar on the topic. It is given by John Wilson who created the company that Mentor acquired back in 2003.

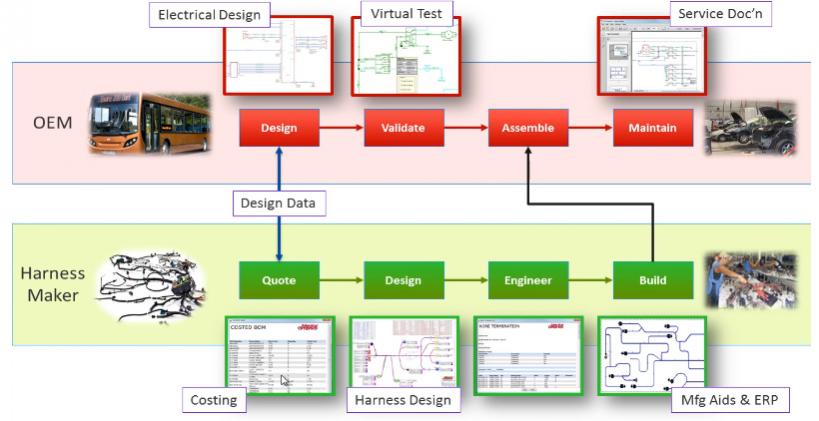

The webinar is Virtual Design, Testing and Engineering Speeds Electrical and Wire Harness Design. It covers the wiring design process and how it integrates into the system and process designing the vehicle itself. Typically harness design is outsourced to supplier who have to bid on it, then design and manufacture it.

VeSys Design provides an intuitive wiring design tool for the creation of wiring diagrams and the associated service documentation. It has integrated simulation facilities that can validate the design as it’s created, ensuring high quality. VeSys Harness is a tool for harness and formboard design tool with automated part selector and manufacturing report generation. It shrinks the design time and automates many steps in the design process. Vesa is a mid-level product for smaller companies.

For larger problems such as aerospace and automotive with more complex harnesses, there is a more powerful product line called Capital. This is oriented towards enterprise level deployment.

View the webinar here. White papers on electrical and wire harness design are here.

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.