This is the seventh in the series of “20 Questions with Wally Rhines”

Probably the most innovative person I met at Texas Instruments, other than Jack Kilby, was Ken Bean. Ken had a list of patents that would impress even the most skeptical. He started his career at Eagle Picher and came to TI in the mid 1960s. He was a warm, delightful and modest person but very innovative when it came to finding solutions for silicon manufacturing problems. He worked in Semiconductor Group Product Divisions as well as research labs over his TI career, as did Mike Cochran, a topic that I’ll address later.

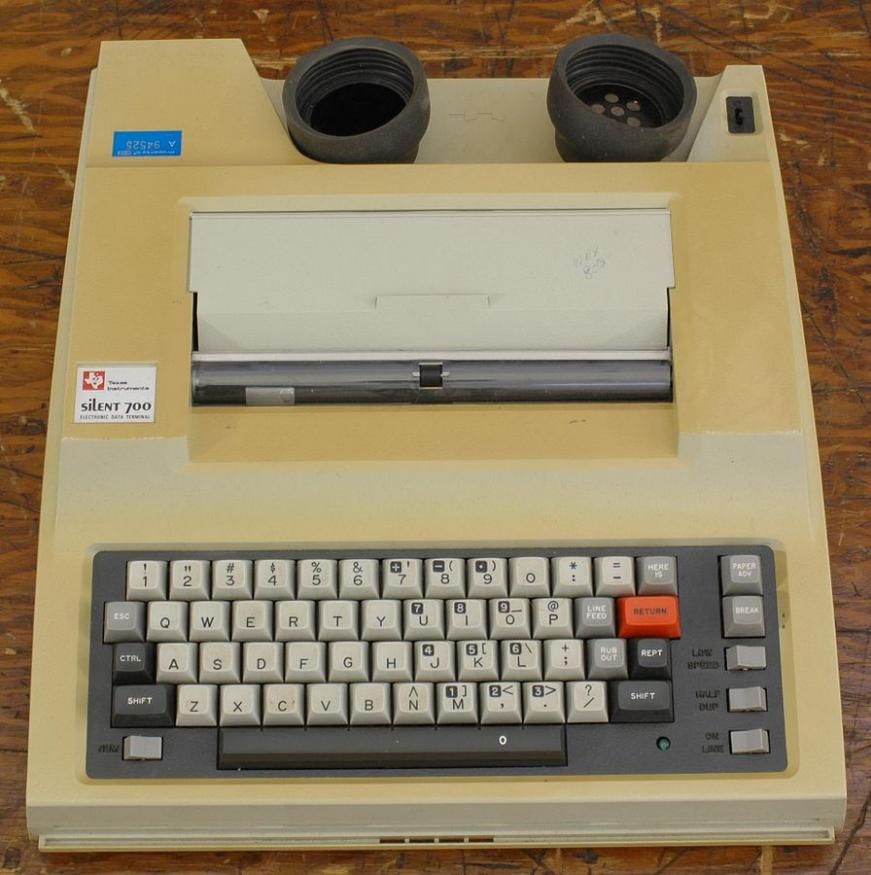

Ken Bean almost never saw a semiconductor manufacturing problem that he couldn’t solve. When TI had problems introducing the “thermal printer” that was used in the “Silent 700”, Ken had a solution that made the silicon print heads manufacturable. One of the most innovative patents that Ken filed was the patent on the slicing of silicon wafers. Easy, don’t you think? No. Ken addressed a problem for DUF (or diffusion under film) in bipolar integrated circuits. “Pattern shift” was a problem that occurred because early bipolar integrated circuits used wafers that were oriented to or crystal planes. As a result, subsequent layers of deposition “shifted” modestly as the epitaxial layer grew in the direction of crystal orientation. This caused a shift in the alignment of subsequent photomasks. Not a problem for Ken. He was called in to solve the problem and he did. Why not slice the wafers a few degrees off the perfect orientation. Then the DUF layer wouldn’t follow the crystalline orientation. It worked. Subsequently, wafers for bipolar integrated circuits were sliced slightly away from perfect orientation.

Ken Bean almost never saw a semiconductor manufacturing problem that he couldn’t solve. When TI had problems introducing the “thermal printer” that was used in the “Silent 700”, Ken had a solution that made the silicon print heads manufacturable. One of the most innovative patents that Ken filed was the patent on the slicing of silicon wafers. Easy, don’t you think? No. Ken addressed a problem for DUF (or diffusion under film) in bipolar integrated circuits. “Pattern shift” was a problem that occurred because early bipolar integrated circuits used wafers that were oriented to or crystal planes. As a result, subsequent layers of deposition “shifted” modestly as the epitaxial layer grew in the direction of crystal orientation. This caused a shift in the alignment of subsequent photomasks. Not a problem for Ken. He was called in to solve the problem and he did. Why not slice the wafers a few degrees off the perfect orientation. Then the DUF layer wouldn’t follow the crystalline orientation. It worked. Subsequently, wafers for bipolar integrated circuits were sliced slightly away from perfect orientation.

In the early 1970s Monsanto decided to get out of the semiconductor wafer business and showed up at TI with a list of patents for which they hoped to claim royalties (since TI still manufactured its own polysilicon and silicon wafers). After Monsanto showed their patents, TI lawyers passed Ken Bean’s patent to them, showing why wafers used for bipolar semiconductors are sliced a few degrees away from the perfect orientation (https://patents.google.com/patent/US3379584A/en). The story goes that the Monsanto lawyers looked at the patent and closed their brief cases. That was the last that the TI lawyers saw of them. It was truly a fundamental patent in the early days of semiconductor history. I loved my interaction with Ken and he loved our family. To his death, he communicated, kept our Christmas cards on his refrigerator and delighted in the success that TI ultimately achieved.

One of the things that Ken taught me was the importance of customer interaction in the innovation process. Ken had assignments in the Semiconductor Group and in the Central Research Labs as well as the Semiconductor Research and Development Lab. Interestingly, he generated patents at approximately the same rate per year regardless of where he was working. The same was true of Mike Cochran, who worked in a variety of organizations in TI, including both semiconductor product groups and research laboratories (and is partially responsible for the Cochran-Boone patents on the microprocessor). I decided to analyze the patent productivity of the truly great patent generators like Ken and Mike. Fortunately, TI had a system that helped me. After the TI DRAM lawsuits, TI management decided that patents were a very important source of royalty revenue, much to the dismay of many TI engineers who had been taught that patents should only be used defensively, to allow TI to enter new markets. So TI created a special segment of the annual performance review process that rewarded the creators of the most valuable patents. Those lawyers who negotiated the patent cross licenses voted on the most valuable patents. The result: I now had a list of the most “valuable” patents.

The result of the analysis amazed me although I wasn’t allowed to publish the results. But the conclusion was clear. People like Ken Bean and Mike Cochran generated about the same number of patents per year. But the ones that they generated when they were in product groups turned out to be much more valuable than those they generated when they worked in research organizations. Why? I concluded that, because the patents they filed when they were in product groups were developed in response to a customer problem, they grew in value as more competitors adopted similar solutions to the same type of problems. The other patents sounded great; they just weren’t as valuable because they were generated by innovative ideas rather than customer problem solving.

The 20 Questions with Wally Rhines Series

Share this post via:

An AI-Native Architecture That Eliminates GPU Inefficiencies