We have been tracking automotive related articles on SemiWiki since 2015 and have published more than 300 automotive blogs thus far that have garnered more than one million views. The automotive publishing pace has picked up quite a bit lately and the number of domains reading them has increased exponentially. So yes, automotive is a big deal for the semiconductor business, absolutely!

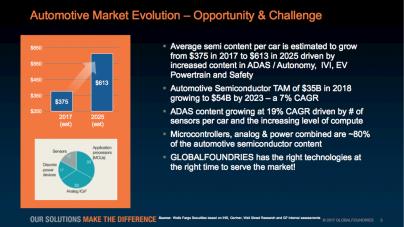

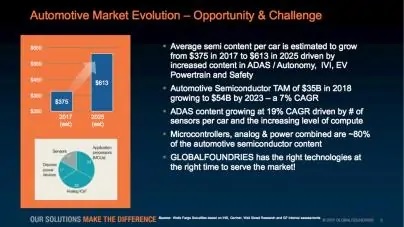

GlobalFoundries has a very nice automotive landing page to get you started. If you look at the market overview you will see the different market segments: Powertrain, Advanced Driver Assistance (ADAS), Infotainment, Body (human) Electronics, Instrument Cluster, Chassis and Safety, and EV.

FD-SOI is also a popular topic on SemiWiki. Since 2013 we have published 90 blogs that have been viewed close to one million times. FD-SOI is also one of the most commented on topics on Semiwiki. In fact, when I first blogged about FD-SOI I immediately thought of two markets: China and Automotive.

Today the automotive market is hot around the world especially in China so the question I had for GlobalFoundries after their latest FD-SOI design win with Arbe Robotics for Resolution Imaging Radar to Enable Safety for Autonomous Cars was: How does FD-SOI compare to FinFET or bulk planar technology for reliability aging?

Reliability aging is one of my biggest concerns with automotive semiconductors especially when talking about autonomous cars. My wife and I generally keep our cars for about 10 years (100,000 miles) and we keep our iPhones for 1-2 years. The National average for new car ownership seems to increase every year and is close to 6 years according to Kelly Blue Book. But the average life of a vehicle is at an all-time high of 10.8 years which matches us since we generally buy new cars.

Jamie Schaeffer, Sr. Director of product line management, at GF gave me the answer I was looking for:

All technologies are qualified to industry standard specifications, performance is the variable that is maximized while still satisfying the reliability limits of a predefined lifetime specification.22FDX, however, provides three unique advantages for reliability aging compared to bulk planar or FinFET technologies:

First, utilizing body-bias to boost frequency has inherently less impact on reliability lifetime compared to the traditional approach of applying voltage overdrive. Body-bias has zero to minimal impact on typical reliability parameters (TDDB, BTI, HCI) compared to voltage overdrive which strongly accelerates reliability aging and restricts design parameters such as Temperature, Lifetime, Area, or PPM.

Second, by using adaptive body-bias techniques the designer can compensate for reliability aging effects in their design. This enables power and area efficiencies by designing with less margin and compensating, real-time, for aging induced performance degradation through the use of on-die process monitors, controller IP, and body-bias generators. The use of body-bias is also more precise, less noisy, and less sensitive to IR drop than applying voltage overdrive techniques.

Third, 22FDX has superior soft-error rate for alpha and neutron radiation compared to bulk technologies giving it an intrinsic advantage compared to bulk technologies for radiation induced aging effects. For single-cell upsets 22FDX demonstrates 30x better FIT/Mbit (failure in time per Mbit) and for multi-cell upsets 22FDX demonstrates >1000x better FIP/Mbit compared to the historical trend of bulk technologies including 28, 40, and 45nm nodes. The improved SER in 22FDX saves layout space and computation overhead for ECC.

Jamie is one of my favorite sources/speakers at GF. He has a PhD from the University of Texas at Austin in Material Science and Engineering and started his career at Freescale in 1997 before joining GF in 2010. If you have more questions for Jamie post them here and I will make sure they get answered.

Share this post via:

TSMC vs Intel Foundry vs Samsung Foundry 2026