We live in an exploding AI world, and this has put pressure on foundries to deliver new products faster than ever before. Any help to accelerate the semiconductor R&D goes a long way to make the life of Fab engineers easier. EDA tools in the TCAD (Technology Computer Aided Design) category are critical for TCAD engineers to accelerating R&D by simulating semiconductor process and devices before anything is manufactured in the Fab. TCAD engineers work with process, integration, and device engineers to provide critical insight into semiconductor manufacturing to reduce R&D cost, optimize the technology node and product faster, and make foundry more profitable.

Synopsys is the industry-leader for TCAD tools, and its Sentaurus suite of TCAD products are considered as the gold standard. One of the main challenges of TCAD engineers is to calibrate the tools to manufacturing data and improve accuracy for their workflows. I recently attended a webinar on Sentaurus Calibration Workbench (SCW), which is one of the recent TCAD tools from Synopsys, that uses ML to help TCAD engineers automate the calibration.

The first time that I heard about Sentaurus it reminded me of the galaxy named Centaurus.

This webinar had three Synopsys people presenting:

- Saurabh Suryavanshi, Product Manager

- Youngkwon Cho, Senior Staff Engineer

- Dipanjan Basu, Principal Engineer

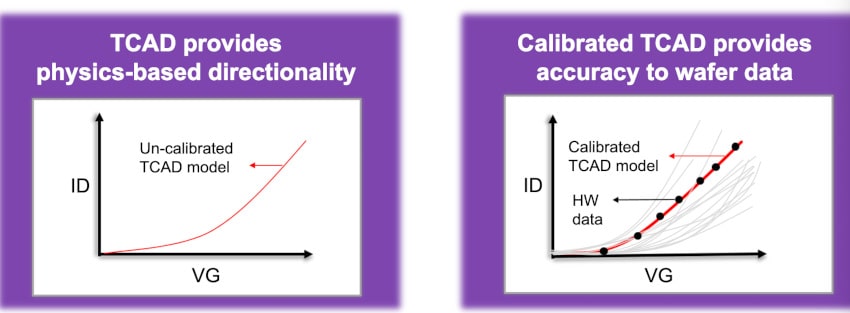

Saurabh explained that TCAD tools provide physics-based directionality and helps engineers perform “what-if” analysis during early stages of R&D. Furthermore, by calibrating the TCAD tools to experimental data the users can improve the accuracy of the models and use the TCAD simulations to supplement wafer-based learning during Technology development and Process Ramp. Calibration of TCAD tools, essentially further elevates the value provided by TCAD tool from “what-if” analysis to improving the efficiency of Fab by reducing R&D cost and time to market.

In the past, TCAD engineers primarily relied on manual methods for calibration, but that approach took too much time and provided sub-optimal results, because it is a complex task and provided little exploration of the parameter space. A newer approach for calibration proposed by Synopsys uses automation by having re-usable workflows with expert modules, adopting the Python language and a simple GUI to improve ease of use, and shortening the calibration time with gradient-based and Machine Learning (ML) algorithms.

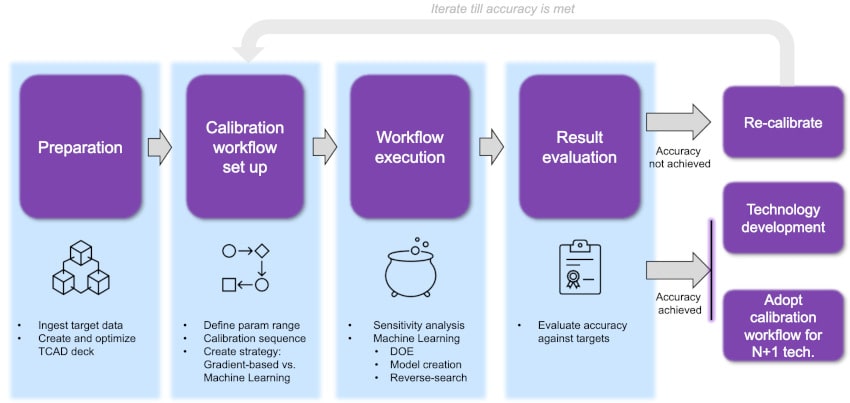

Here is what an end-to-end calibration workflow looks like –

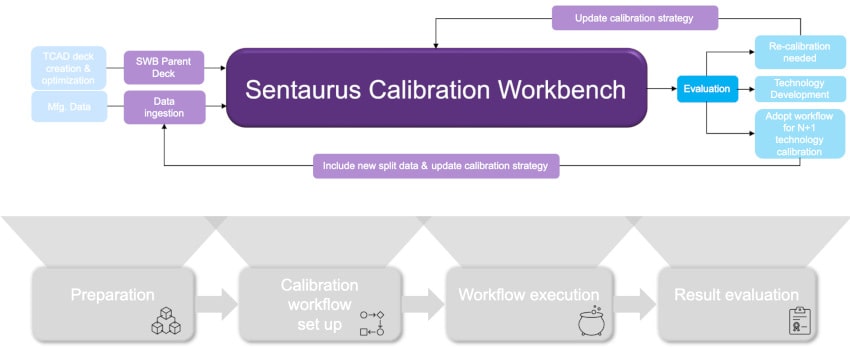

The Sentaurus Calibration Workbench helps a TCAD engineer navigate the end-to-end calibration workflow by helping with set up and execution of the calibration workflow, from data preparation to workflow setup to execution to evaluating the results.

Youngkwon showed how you can prepare a new project from a Sentaurus Workbench (SWB) parent deck in developing a calibration workflow, then use that in SCW. For the calibration workflow setup phase, you can use both the tool GUI and a Python API. SCW provides both gradients based as well as machine learning model for calibration.

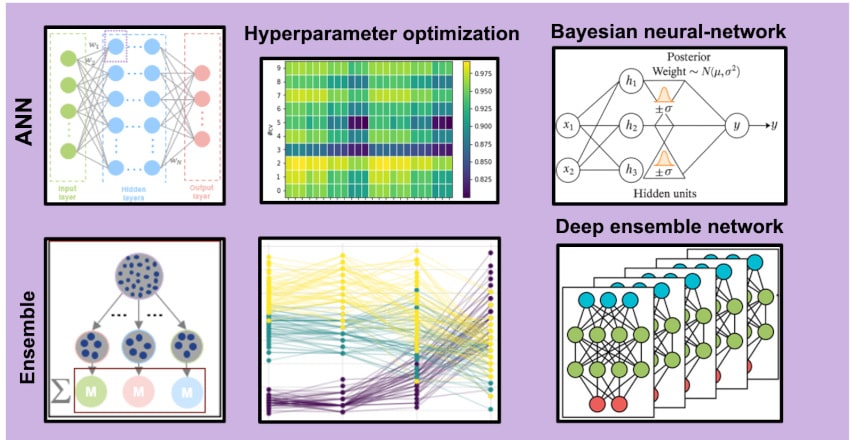

Synopsys has adopted and enhanced open-source models for the ML-based workflows. SCW provides support to both expert users as well as new users by supported low-level as well as high level ML models. In addition, Synopsys provides expert written application notes that provide an end-to-end calibration workflow for critical calibration applications such as CMOS and SIMS. The high-level ML model as well as application notes provide a quick start-up option for users. For expert users, SCW also allows users to bring in their own custom model written either in PyTorch or TensorFlow.

For ML-based workflow, you define the DOE and optimize the number of simulations. Furthermore, the user can run sensitivity analysis to identify most critical parameters. Youngkwon highlighted these two features as most critical for reducing the time to calibration.

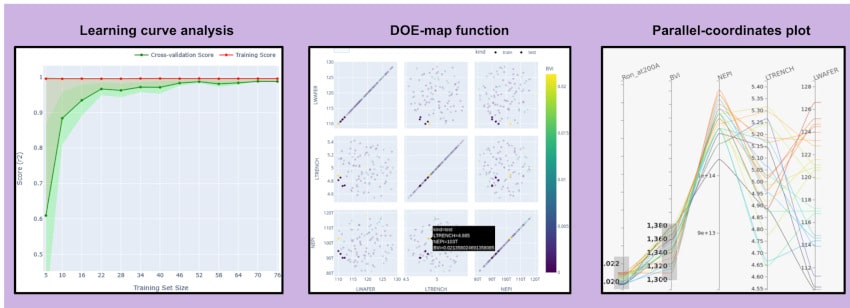

The final phase of using SCW is the result evaluation where ML visualization provides interactive graphs for advanced analytics, plus you may create custom tasks with your own ML models. With learning curve analysis, you examine how model scores change with training set size. The DOE map function examines the error distributions, finding areas of low predictive power. On the parallel coordinates plot it shows optimal conditions or finds outliers through the connections between input and output.

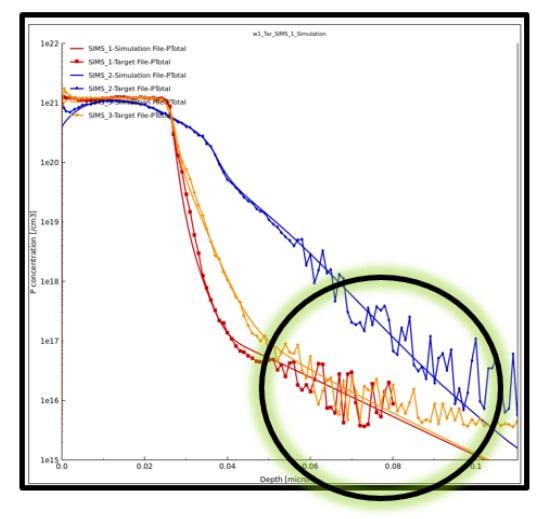

Dipanjan shared key use-cases on CMOS calibration, 1D SIMS calibrations, hierarchical model calibration, and mobility calibration in GaN devices. All these applications are available for existing users through SolvNet. The CMOS calibration, which usually involves dozens of parameters, showed the true power of workflow automation provided by SCW. The entire calibration was divided into 5 workflows, where parameters were calibrated one step. The SIMS calibration is a great example of using SCW to not-only handle multiple parameters but also multiple targets and multiple implant species. The final validation step re-runs the TCAD simulation with the calibrated parameters to evaluate the model, showing that the model fits closely with experimental data post-calibration as shown by the figure below.

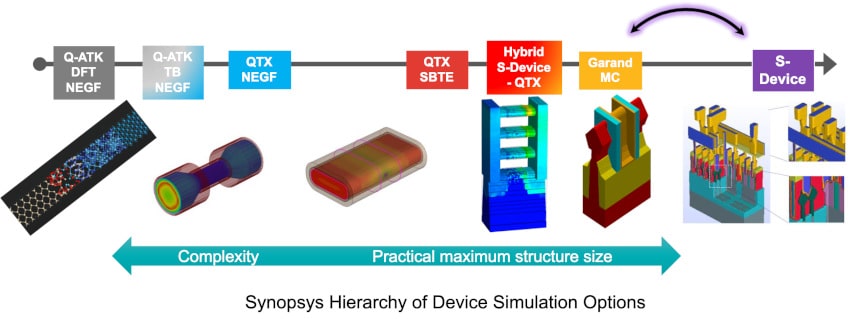

Dipanjan also shared Hierarchical modeling using the Garand Monte Carlo (GMC) in the Sentaurus Device (S-Device) tool was presented for 3D structures. This was a unique case, where calibration is not done against the experimental data but between two modeling frameworks. Such calibration allows users to attain accuracy of GMC simulation, while maintaining the speed of continuum modeling in S-Device.

Towards the end, Saurabh shared three customer success stories. In the first story, he showed an order of magnitude improvement in calibration at a memory customer. This was possible by following the right practices throughout the end-to-end calibration workflow and utilizing SCW as prescribed in the workflow. He also shared a success story at an advanced logic customer, where they had a 3X improvement in simulation time by moving from gradient-based calibration to ML-based calibration. Lastly, he shared the success at a mature node customer where the calibration was impossible by manual methods. They used SCW to define an iterative flow and used ML to achieve calibration with mere low hundreds of DOE simulations. All these success stories showed significant quality of result while helping users to reduce the time-to-calibration.

Summary

Device and process development are daunting tasks for foundries to undertake, so any automation is welcomed to speed up TCAD simulations. Synopsys has responded to this challenge by bringing ML technology into the TCAD calibration flow in their Sentaurus Calibration Workbench (SCW) tool, bringing about 10X faster time to results even with more than 50 parameters. This tool is widely application across the industry including memory, logic, as well as specialty device manufacturer.

View the archived webinar online.

Related Blogs

- TCAD Enables Moore’s Law to Continue

- FinFET Modeling and Extraction at 16-nm

- Designing with FinFETs

- Samsung, Synopsys, GLOBALFOUNDRIES and ARM at DAC

Comments

There are no comments yet.

You must register or log in to view/post comments.