GDS and LEF/DEF each came about to support data exchange in different types of design flows, custom layout and place & route respectively. GDS (or stream format) was first created in the late 1970s to support the first generation of custom IC layout tools, such as Calma’s GDSII system. Of course, the GDS format has been updated over the years to support the capabilities of newer IC design tools. LEF/DEF (library exchange format & design exchange format) came along later to support the larger but somewhat simpler data found in P&R flows. Yet there has always been a dichotomy of support for these formats among various design tools. DFM has tended to fit in between custom layout and P&R, with the general assumption that reading LEF/DEF and writing GDS made sense because at or near tape out the flow would move to GDS. However, this has always been problematic because P&R systems have grown more powerful and designers want to see the final layout in them as opposed to custom tools at the end of the flow.

DFM (design for manufacturing) tools, such as Siemens EDA’s Calibre YieldEnhancer, provided a path to DEF so DFM changes could be brought into P&R tools. But the flow was cumbersome and often required steps not in foundry approved rule decks. Siemens EDA now has a white paper that discusses the addition of a fully bidirectional DEF flow for their DFM tools. The paper, titled “Optimizing the Integration of DFM and P&R” by Armen Asatryan and James Paris describes the limitations of the previous extra conversion step to get to DEF and then talks about their new direct write to DEF.

The previous DEF conversion process involved a utility called fdiBA which ran as a separate operation. It involved extra steps and needed inputs for attaching net names to geometry. It had limitations on geometry shapes and did not deal well with multiple orientations of vias. With larger design sizes it tended to face capacity limits and long runtimes.

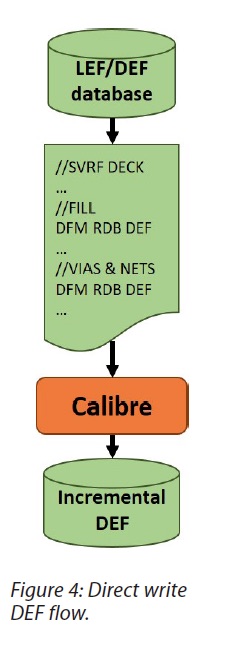

The new direct write DEF feature in Calibre can create a DEF format database without the need for an intermediate GDS (or OASIS) database conversion. To take advantage of this, only one rule deck option needs to be added – “DFM RDB DEF”. Along with the obvious simplicity of the flow, there are a number of added benefits. Direct write to DEF supports all-angle metal shapes, including metal extension end-caps and via caps. It recognizes multiple orientations of via instances. To reduce size, it performs via array detection. Direct write DEF also provides automated via repair.

One area that will make a big difference is the treatment of fill. Compressed fill is handled properly with direct write to DEF so Calibre YieldEnhancer SmartFill can efficiently transfer fill to P&R tools.

Having been in this industry as long as I have, I am often amazed at the longevity of the GDS format. I actually knew Sheila Brady, the woman who created the GDS format. Even back in the 80’s she would comment on how it had taken on a life of its own and was initially really just intended as a quick and reliable back up for GDSII databases. Yet here we are with complicated flows that rely on legacy formats such as this. Making rational the movement of P&R data between essential tools in the flow with DEF is vital as design size and complexity increase. The full white paper is available for download here.

Also Read:

Automotive SoCs Need Reset Domain Crossing Checks

Siemens EDA is Applying Machine Learning to Back-End Wafer Processing Simulation

CDC, Low Power Verification. Mentor and Cypress Perspective

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.