In a significant example of how high-tech manufacturing can embrace environmental stewardship without compromising operational excellence, Taiwan Semiconductor Manufacturing Company has launched a sustainability initiative within its advanced packaging operations that both reduces waste and generates meaningful economic value. This drive, centered on TSMC’s CoWoS® (Chip on Wafer on Substrate) advanced packaging technology, demonstrates how innovation in recycling and circular practices can transform manufacturing byproducts into valuable resources resulting in annual green benefits of approximately NT$700+ million ($22M+ USD), alongside substantial carbon reduction.

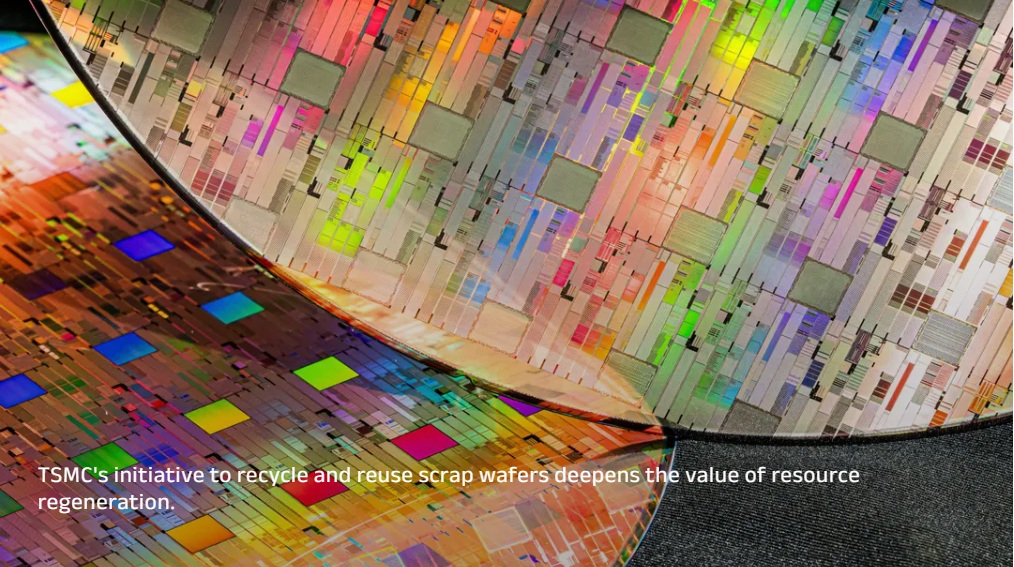

At the heart of this sustainability effort is the repurposing of scrap or “waste” wafers, silicon discs produced and later deemed unsuitable during front-end production. Traditionally, such wafers are discarded once they fail to meet performance or quality specs. However, these silicon substrates still contain high-grade material and structural integrity valuable for secondary uses. Recognizing this, TSMC’s Materials Supply Chain Management Organization, in collaboration with its Advanced Packaging Technical Board and external suppliers, developed a specialized processing technology that turns scrap wafers into dummy dies, components essential in the CoWoS packaging process to maintain structural stability.

Dummy Dies and CoWoS®

To understand the significance of this initiative, one must appreciate the role of dummy dies in advanced semiconductor packaging. In CoWoS® technology, multiple active chips are stacked and integrated onto an interposer and substrate to create powerful multi-chip modules for high-performance computing, AI accelerators, and networking devices. During this process, dummy dies are inserted to fill space, balance mechanical stress, and maintain uniform thermal and electrical profiles. These are typically cut from brand-new wafers, which makes them a non-trivial fraction of packaging consumption—especially as demand for CoWoS® scales with burgeoning markets like AI, cloud computing, and advanced graphics.

Instead of using all new wafers to produce these dummy dies, TSMC’s cross-functional team developed a rigorous recycling methodology for scrap wafers. This involves selection, grinding, cleaning, and precision inspection to ensure recycled wafers meet the same strict quality requirements as newly sourced material. After processing, these recycled wafers are cut into dummy dies that are functionally and structurally suitable for CoWoS® assembly. This innovation not only salvages silicon that would otherwise go to waste, but also significantly shifts material sourcing dynamics toward sustainability.

Economic, Environmental, and Operational Impact

Early reports on the initiative’s outcomes have been compelling. As of late 2025, recycled wafers re-manufactured into dummy dies have been deployed across multiple advanced backend facilities, including Advanced Backend Fab 3, Fab 5, and Fab 6. The result is an estimated reduction of 10,205 metric tons of carbon emissions annually, underscoring a meaningful contribution toward TSMC’s broader climate goals. On the financial front, TSMC anticipates that this reuse of scrap wafers will generate a green benefit amounting to NT$746 million per year surpassing the NT$700 million mark cited in sustainability narratives.

This initiative exemplifies a practical circular economy model within semiconductor manufacturing: instead of viewing scrap material as waste to be disposed of at environmental cost, it becomes a resource to be refined and reintegrated into production. Beyond direct savings and emissions reductions, there are supply-chain ripple effects that encourage vendors and partners to invest in recycling technologies, improve material lifecycle tracking, and innovate in waste valorization.

TSMC’s approach aligns with its broader Environmental, Social, and Governance (ESG) strategy, which emphasizes resource circularity, energy efficiency, and environmental protection across its global operations. The company has consistently integrated sustainable practices—such as waste recycling programs and comprehensive environmental management—into its long-term operational blueprint.

Looking Forward

Looking ahead, TSMC plans to further expand the scope of recycled wafer use across different packaging technologies and processes, potentially including InFO (Integrated Fan-Out) packaging and beyond. By continually optimizing these techniques and extending collaboration across its supply chain, the company seeks to maximize resource efficiency while maintaining the highest product quality standards, a hallmark of its global leadership in semiconductor manufacturing.

Bottom line: TSMC’s CoWoS® sustainability drive encapsulates how bold environmental action and industrial innovation can work hand-in-hand, turning what was once waste into wealth economically and ecologically alike.

Also Read:

TSMC’s 6th ESG AWARD Receives over 5,800 Proposals, Igniting Sustainability Passion

TSMC based 3D Chips: Socionext Achieves Two Successful Tape-Outs in Just Seven Months!

Why TSMC is Known as the Trusted Foundry

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.