- MEMS technology has become mainstream.

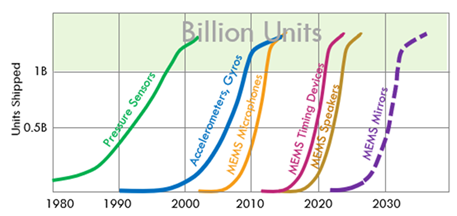

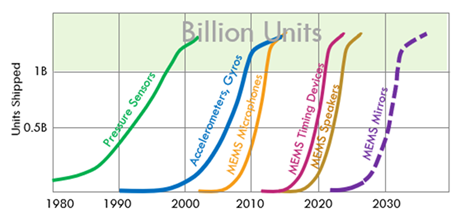

- Multiple product categories have reached high volumes of shipping more than a billion units/year. These are: pressure sensors, accelerometers and gyros, microphones, silicon timing devices, and speakers.

- The next big wave in MEMS technology in the next ten years is MEMS Mirrors. They are expected to reach a high volume in shipping of billions/year.

Last month, Lj Ristic delivered an invited talk on MEMS technology as a driving force at the Laser Display and Lighting Conference 2025, held at Trinity College Dublin. His talk included a review of some major successes of MEMS industry. We used that occasion to talk to him and discuss some major achievements and the status of MEMS technology today.

Dr. Lj Ristic is recognized for his pioneering contributions to the field of semiconductors, particularly in the development and commercialization of MEMS technology. He has been instrumental in creating innovative MEMS products, with hundreds of millions of units shipped globally. He is also credited with inventing a microprocessor with integrated sensing capabilities—widely adopted in smart sensors. Among his other notable achievements is the development of a novel method for integrating front-end antenna solutions for RF and wireless systems, which has been widely used by the mobile telecommunications industry. He has also conducted groundbreaking research in magnetic field sensors, advancing one- to three-dimensional sensing using lateral bipolar transistors. Dr. Ristic has also published ‘Sensor Technology and Devices’, the first book to introduce MEMS technology to general public.

In addition to his technical accomplishments, he has held senior leadership roles at major corporations and startups alike, including Motorola, ON Semiconductor, Alpha Industries, Sirific, Coniun, Crocus, and SensSpree. He currently serves as Chief of Business Development and Strategy at Mirrorcle Technologies, a leader in the development of MEMS mirror technology and products.

What can you tell us about the status of MEMS Technology today?

Let us briefly look at the history of leveraging Si as mechanical material. In the early 80’s Kurt Petersen opened the eyes of the rest of the world by saying, look silicon is not the only majestic material for integrated circuits, but it is equally majestic for its mechanical properties at micro scale. Why not leverage that? Of course, at the time it was considered to be exotic and on fringe. Then in 1983 Roger Howe and Prof. Muller came with surface micromachining, creating an additional toolbox for making micromechanical structures. And the race was on. Big companies jumped in, including Motorola (I was there), and they focused on leveraging this technology for automotive applications. Where there is a will and funding, there is success. 40 years later MEMS technology is the mainstream and MEMS products are delivered in billions per year serving all possible markets including automotive, commercial, consumer, communications, industrial, biomedical, space, and robotics.

What was the first MEMS product to gain credibility?

It is important to point out that the acronym MEMS was coined by Jacobs and Wood in 1986 in their proposal for grant to DARPA, and it was used to describe micro electro-mechanical systems consisting of micro-mechanical devices and driving electronics. Since micromechanical devices described in the proposal were made using surface micromachining, often the phrase MEMS at that time was associated with surface micromachining. In years to come, the acronym MEMS technology has evolved into an umbrella to include all aspects of micromachined devices, from bulk machining, to wafer bonding, to surface micromachining.

Going back to the question, considering the historic content and initial meaning of MEMS, one can say the first product that gave credibility to MEMS technology was an accelerometer developed for automotive industry. In the late 1980s and early 1990s, Motorola and Analog Devices led the development of accelerometers for airbag applications, neck and neck. While Analog Devices adopted the comb-structure approach invented by Howe and Lee, Motorola pursued its own distinct path of developing a three-polysilicon-layer surface micromachining technology and a differential capacitive device as the vertical stack, that became the foundation for its accelerometers. Ultimately, both companies were successful in introducing accelerometers to automotive customers, in volume production, and they showed that surface micromachining may take many shapes and flavors. Thus, the MEMS accelerometer has a distinct place of putting MEMS technology on the industrialization map. It should be also pointed out that the success of MEMS accelerometer without coupling the sensing element with CMOS ICs would have been impossible. This is an excellent example of the fusion of two technologies, MEMS and CMOS, to give something new that none of these technologies could do on their own,

Since the 1990s, MEMS accelerometers have significantly expanded their range of applications. Advances in miniaturization, high-yield manufacturing, and cost-effective production have driven their continued growth in the automotive market and facilitated their widespread adoption across new markets, including consumer electronics, industrial automation, robotics, medical devices, the Internet of Things (IoT), and defense. Today, MEMS accelerometers play a crucial role in applications such screen orientation detection, movement monitoring, step counting, gesture recognition, structural health monitoring, and vibration monitoring of machinery, among many others.

Current leaders in accelerometer products are Bosch, TDK-InvenSense, NXP, STM, ADI, Murata, and others.

Where do pressure sensors stand in acceptance of MEMS technology?

Pressure sensors are a granddaddy of silicon sensors and transducers. They typically leverage a piezoresistive effect that was discovered in mid 50s in silicon and germanium. It took more than a decade before the first commercial pressure sensors started appearing in the late 60s. They were made by using bulk micromachining to create thin silicon diaphragm that contain resistors diffused into it. Kulite was the first company to leverage piezoresistive effect using silicon. Many others followed. I firmly believe that without pressure sensors MEMS technology would not have been today where it is. The pressure sensors were predecessors to the broader field of MEMS technology as we know it today. They were the base on which we started building to achieve the status of mainstream technology – the MEMS is currently.

It should be mentioned that among numerus pressure sensor products in existence two product categories deserve a special place because of the impact they have had since their introduction. These two are MAP (Manifold Absolute Pressure) sensor and TPMS (Tire Pressure Measurement System). MAP is essential in maintaining efficient fuel injection of the engine, while TPMS is used for real-time pressure monitoring. Motorola/Freescale (today part of NXP), as a leading supplier of semiconductor products to the automotive industry, has contributed significantly to the reputation of these two products. Both are crucial in improving overall efficiency and safety management of vehicles and that is what puts these two in the special category on their own.

Current leaders in pressure sensor products are Bosch, STM, NXP, Honeywell, Infineon, and others.

What are the other significant achievements that have contributed to the credibility of MEMS technology?

With the success of accelerometers, the progress in development of other products was relatively fast. The MEMS gyro followed and then the integration of MEMS accelerometer and gyro in the single chip. Then others. Today, the list of MEMS products in existence is literally endless, but I will focus here on the exclusive club of products that have unique distinction of being made in billions per year. In addition to pressure sensors and accelerometers and gyros, the other products that make exclusive 1 billion units/year club are microphones, speakers, and timing devices.

Microphones have significantly benefited from ongoing advancements in MEMS technology, leading to substantial miniaturization of these devices. As a result of their small size and low power consumption, MEMS microphones are well-suited for applications in compact, battery-powered devices such as smartphones, tablets, smartwatches, earbuds, hearing aids, laptops, smart speakers, etc.

Current leaders in microphone products are Knowles, Goertek, Bosch, Cirus Logic, Infineon, and others.

MEMS speakers are among the latest product families to leverage MEMS technology, with commercial products emerging only over the last decade. Their development has generally been more challenging compared to MEMS microphones. This challenge is primarily driven by the need for large diaphragm displacement. On one hand, sufficient power is required to generate enough force to move the diaphragm, while on the other hand, the structural integrity of the diaphragm must be preserved despite the large displacement requirement. The advantages of MEMS speakers over traditional non-MEMS technologies (such as electrodynamic and balanced armature speakers) are their small form factor, lower power consumption, and ease of integration with electronics. These benefits make them highly attractive for many applications in consumer electronics and other size- and power-constraint applications.

Current leaders in speaker products are xMEMS, Usound, Bosch, Sonitron, SonicEdge, and others.

The MEMS timing devices are used to provide clock functions that are required in modern electronic products. From a functional point of view, they can be divided in three categories: resonators, oscillators, and clocks, and all of them can be made as silicon MEMS devices. They are an excellent alternative to classical quartz crystal timing devices and are gaining acceptance in many market segments including automotive, aerospace and defense, telecommunications, IT, consumer, and medical applications. They offer reliable performance, low power consumption, high stability, small form factors, and low cost. Current leaders in MEMS timing device segment are Si-Times, Microchip, Kyocera, Abracon, Rakon, and others.

In the end, a general assertion can be made for all MEMS products: they gained reputation because they perform reliably, they offer small power consumption, small form factor, and low cost, and that is a winning combination.

What is the latest in MEMS Technology?

One of the latest group of products developed in MEMS technology are silicon MEMS Mirrors that are essential for many applications in optoelectronics. MEMS Mirrors are small silicon-based devices capable of tilting along a single axis (one-dimensional mirror) or in two axes (two-dimensional mirror). Depending on their design they can also move along a third axis making a piston action. What makes them special are small diameters usually ranging from 0.5 mm to 10 mm, and their thickness, around only 40 um, which is thinner than the average thickness of human hair. The technology for making MEMS mirrors has significantly matured over the last two decades and these products are at the cusp of experiencing tremendous growth in the next decade.

A MEMS mirror’s primary function is to deflect a focused beam of light in different directions. The light beam can be steered along a single axis (one-dimensional mirror) or along two axes (two-dimensional mirror). This ability to receive and redirect a focused beam of light is fundamental to scanning technology.

The scanning capability of MEMS mirrors is cleverly utilized to enable two basic functions for manipulating laser light: directed light projection and directed light acquisition (imaging). In almost all MEMS Mirror applications these two basic functions are explored, and the rest are custom additions tailored to specific applications. And customers tell us applications are numerus from automotive and transportation to AR/VR, from consumer and commercial to industrial, from biomedical to free space optical communications, from robotics to smart city. I firmly believe MEMS Mirrors are the next big wave in MEMS technology in the next decade, poised to reach an annual production volume of billions/year.

Current leaders in MEMS Mirror products are Mirrorcle, Hamamatsu, Bosch, Sercalo, Ultimems, and others.

Stay tuned!

Also Read:

WEBINAR Unpacking System Performance: Supercharge Your Systems with Lossless Compression IPs

Siemens EDA Unveils Groundbreaking Tools to Simplify 3D IC Design and Analysis

Share this post via:

Facing the Quantum Nature of EUV Lithography