The transformation of the vertically integrated electronics value chain to a disaggregated supply chain has brought tremendous value to the electronics industry and benefits to the consumers. This transformation has driven the various players to become highly specialized in order to support the market trends and demands of the marketplace, creating a highly complex and specialized electronics supply chain network.

While this transformation has helped deliver very advanced and highly complex electronics systems, information exchange still relies on outdated methods from decades ago. Thus, component manufacturers and system design companies still use PDF and Excel files to exchange information during the design and manufacturing phases of a product. These means of communication won’t go away, but it is high time they be augmented with high bandwidth, dynamic methods that more tightly bring together the nodes of the value chain, while speeding the delivery and ensuring the quality of data. To make this a reality, the electronics industry is embracing the adoption of component data exchange through a digital thread. A digital thread is the communications framework that allows a connected data flow and an integrated view of product data throughout the product life cycle– spanning ideation, realization, and utilization.

Siemens EDA recently published a whitepaper that examines how the emergent component digital thread will revolutionize the electronics industry by connecting all nodes of the value chain.

Industry Standard for Data Exchange

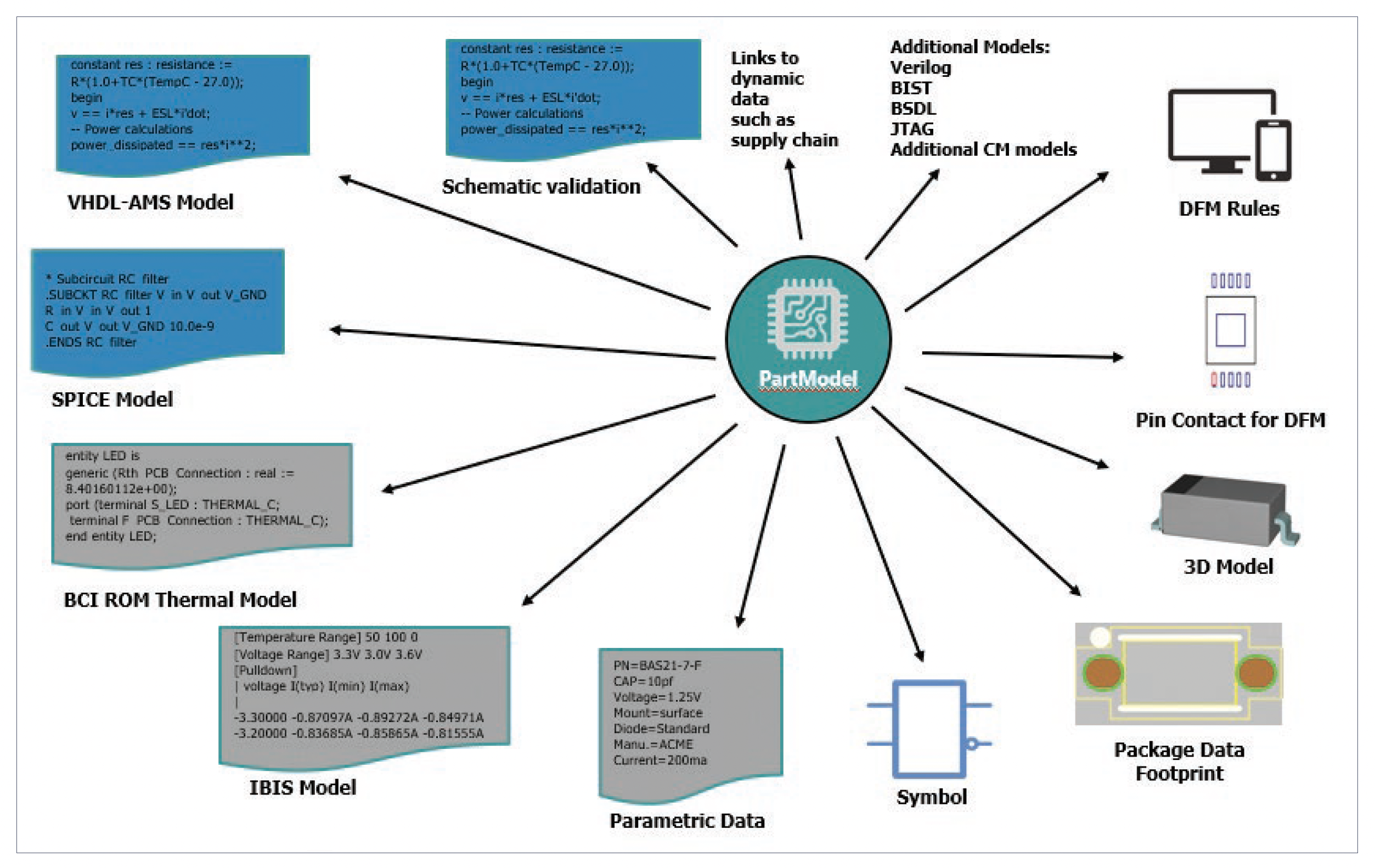

The component digital thread relies on an industry standard known as the JEDEC JEP30 Part Model. This standard, ratified in 2018, establishes requirements for exchanging part data in the electronics industry. The JEP30 Part Model defines the digital twin for electronic components, connecting the virtual and physical worlds across the value chain. It combines comprehensive component information into an industry-standard-based digital container, allowing seamless data exchange and integration throughout the product creation lifecycle. The adoption of this standard is a game-changer, enabling frictionless value and direct consumption by tools in the electronics industry.

Creating and Driving Value and Trust into the Supply Chain

The component digital thread empowers component manufacturers to provide accurate and intelligent data, eliminating errors and accelerating the design-in process. These threads contain embedded trust and supply chain intelligence, enabling better decision-making throughout the product lifecycle. The industry is embracing the JEDEC JEP30 Part Model standard to create high-bandwidth connections and leverage AI-enabled insights. As more tools become available to support the transition, component manufacturers are shifting towards part model representations to enhance collaboration and streamline processes.

Inserting Trust

As the shift towards digital twins of component data accelerates, establishing trust in the component information becomes crucial. Part models serve as complete digital representations of parts, and in the future, different sections of these part models may assimilate digital signatures to create an immutable ledger that builds trust throughout the design chain. Parts will have a “root of trust” tied to their digital certificates, verifying their authenticity and integrity. Similarly, at the product level, manufacturers will establish a “root of trust” through digital certificates that attest to the integrity of the manufacturing process. The digital thread is essential for enabling this trust-building process, as it ensures transparency and traceability throughout the supply chain.

Digital Data Sheets

The part model approach offers additional benefits in the form of interactive data sheets and application notes in digital form. With interactive data sheets, users can access 3D views of the package, interact with live test setups tailored to their specific application conditions, and evaluate real-time supply chain information. They can also access the latest ECAD and mechanical models derived directly from the source part model.

Interactive Virtual App Notes and Eval Boards

Component manufacturers can enhance the evaluation process by deploying cost-effective and instantly available virtual evaluation boards. These boards can be accessed directly from the manufacturer’s website, eliminating the need for logistics, assembly, and shipping. Virtual evaluation boards offer the advantage of being application-specific, allowing end customers to explore the capabilities of a component in a system context and address performance issues upfront.

Accelerating Resilient Electronics Systems Designs

By leveraging part models, first-pass success rates are improved as risks associated with time delays and human error are minimized. Part models enable advanced searches for specific component features, facilitating easier selection and incorporation into designs. Furthermore, the design capture process is transformed, significantly reducing the time required to capture complex designs. The overall impact is substantial time and budget savings, eliminating the need for extensive model content searching, resolving data integrity errors, decoding naming conventions, and avoiding unnecessary respins.

Summary

The electronics industry is undergoing a significant transformation by converting component data into industry-standard digital twins. This shift from PDF-based interactions to high-bandwidth, intelligent digital part model threads will unleash innovation and revolutionize the industry. It will accelerate the design process, increase profitability, and unlock the full potential of engineering teams. This digital transformation will have a profound impact on all stakeholders in the electronics value chain, enabling greater efficiency and fostering new levels of innovation.

The whitepaper will be a valuable read for everyone involved in the design and manufacturing of electronic products.

Also Read:

DDR5 Design Approach with Clocked Receivers

Getting the most out of a shift-left IC physical verification flow with the Calibre nmPlatform

Securing PCIe Transaction Layer Packet (TLP) Transfers Against Digital Attacks

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.