mustache143

New member

While confirmation came over the Easter weekend that Globalfoundries 14nm finfet process was in full production ramp, it was the Chipworks tear down of a retail S6 that caught my attention.

Inside the Samsung Galaxy S6 | Chipworks Blog

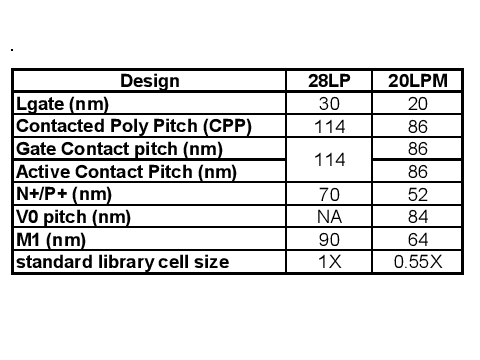

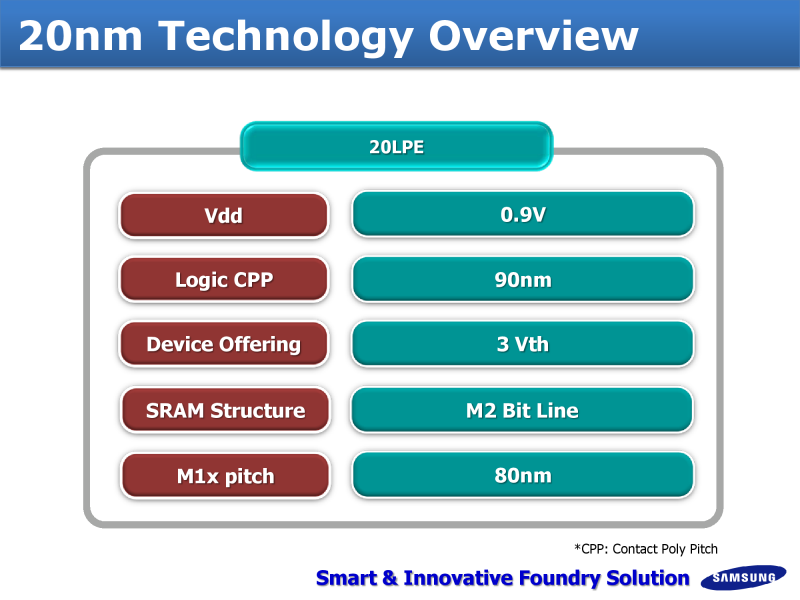

It seems Global may actually be making some of the chips for the S6, as indicated by the marking on the retail chip itself. Living in Albany, I can say the barroom buzz would confirm this. Perhaps Samsung needed additional fab capacity or this chip at ~78sq-mm is a good process validation chip for the copy-'almost exact' that Samsung and GF are using. I'd be interested in people's opinion on the shrink from the 20-nm 5433 to the 14-nm finfet 7420 from ~113 to ~78mm. Definitely not just 20nm with finfet... although denser libraries could have helped a lot.

Inside the Samsung Galaxy S6 | Chipworks Blog

It seems Global may actually be making some of the chips for the S6, as indicated by the marking on the retail chip itself. Living in Albany, I can say the barroom buzz would confirm this. Perhaps Samsung needed additional fab capacity or this chip at ~78sq-mm is a good process validation chip for the copy-'almost exact' that Samsung and GF are using. I'd be interested in people's opinion on the shrink from the 20-nm 5433 to the 14-nm finfet 7420 from ~113 to ~78mm. Definitely not just 20nm with finfet... although denser libraries could have helped a lot.