I remember it like it was yesterday. I was sitting at lunch with good friend Scott Santandrea, explaining my struggles to get traction with the sales channel for the Analog to Digital Converter product line I was managing. My business line had been spending a lot of resources developing high-performance 24-bit delta sigma and 20-bit SAR ADCs. I was frustrated with being aced out by microcontrollers with crummy integrated ADCs. As we kicked around ways to gain mindshare with the Maxim and distributor sales forces, Scott dropped a line on me that I’ve never forgotten:

“Do you care about what you’re measuring?”

That’s it! Because if you care about what you’re measuring for your analog to digital conversion, you should clearly choose my product line. I loved it. I started using the tagline with the field immediately. If you care about what you’re measuring, why would you use an ADC inside a microcontroller? One that was specified as 12 bits but with 8 actual bits. Or listed at 16 bits and providing 10 or 11 bits.

Now, in fairness, the year was 2011 and microcontroller ADCs have come a long way since then. As have discrete ADCs. More on that later.

On a personal level, I look back and it’s a sentence that has defined my career. From my years of marketing ADCs and DACs, to my current role as an account manager, “do you care about what you’re measuring?” has guided me (and many others in the measurement field, I’m certain). If you’re an industrial company measuring eddy currents on turbines, you care about what you’re measuring. If you’re making weigh scales for trucks, you care about what you’re measuring. If you’re detecting particulates in blood or other fluids and need a high degree of accuracy, you definitely care about what you’re measuring. If you’re developing a MIMO WLAN transceiver and need to upgrade from 1024 QAM to 4096, you care about what you’re measuring.

The beauty of the question is that it applies for so many different applications.

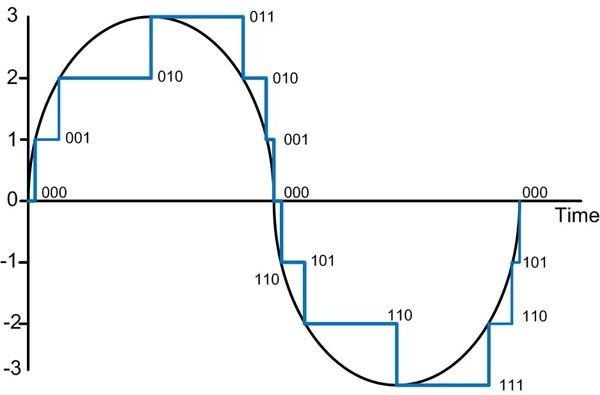

Having spent the majority of my career in the analog mixed signal space, I’ve loved countering the notion that “everything is going digital” with “the real world is analog and always will be.” In order go get those measurements into the digital domain, or from digital back to analog, you need ADCs and DACs. The truth is that not every ADC or DAC conversion needs to be high quality. Sometimes, you just need to know your battery voltage is 3.3V and not 2.5V. Or that a temperature reading across a thermistor equates to 25C and not 50C. In those cases, a micro’s ADC will work just fine – and the cost is essentially free in 2020. But when you care about the difference between 3.31V, 3.30V and 3.29V, or the difference between 24.9C and 25.0C, that’s when you care about what you’re measuring.

For the next few weeks, I’ll be writing a series of posts centered around the question of “Do you care about what you’re measuring?” I’ll cover ground sensing in server applications. Vibration analysis in turbines and windmills. Error vector magnitude for QAM modulation. Accurately measuring sleep state currents in CPUs and GPUs.

What’s the toughest thing you’ve had to measure? What’s your favorite data converter and why? I welcome your feedback on your experiences working in the analog mixed signal domain.

Memory Matters: Signals from the 2025 NVM Survey