![]()

Rapidus 2nm is Japan’s flagship next-generation logic process node, under development by Rapidus Corporation in collaboration with IBM and imec, targeting high-performance, energy-efficient, leading-edge semiconductor manufacturing. The goal is to achieve mass production readiness by 2027, marking Japan’s re-entry into the forefront of advanced logic manufacturing after decades of decline.

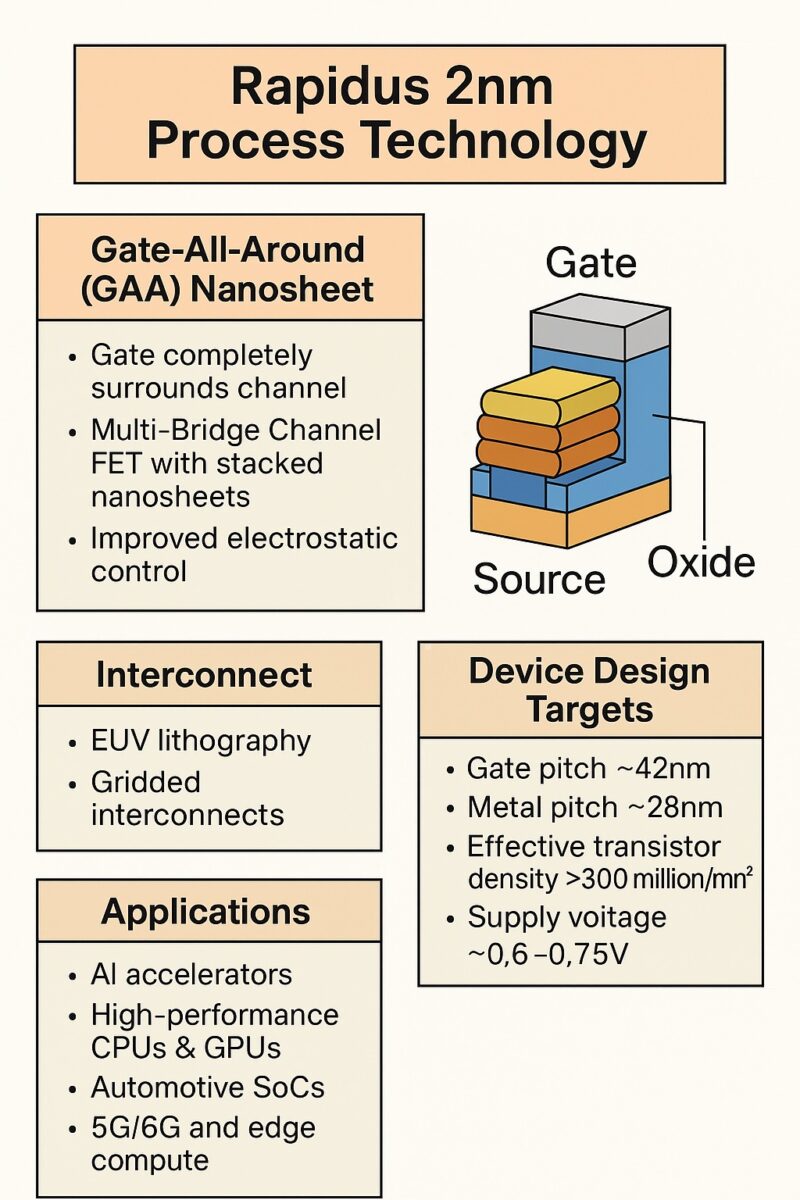

Built upon Gate-All-Around (GAA) nanosheet transistor architecture, the 2nm node represents a leap beyond FinFET scaling limits and is designed for applications in AI, HPC, automotive, and 6G communications.

Key Features

| Feature | Description |

|---|---|

| Transistor Type | GAA nanosheet (also known as Nanosheet FETs) |

| Gate Length | Sub-20nm, multi-stack sheets |

| Node Scaling | True 2nm-class dimensions based on metal pitch and contacted gate pitch |

| EUV Lithography | Uses extreme ultraviolet (EUV) lithography throughout the BEOL and FEOL |

| High Performance | Expected >45% performance gain compared to 7nm FinFET |

| Energy Efficiency | Estimated >75% power reduction at equivalent performance |

| Density | >2x transistor density improvement over 7nm |

| Backside Power Delivery (Planned) | Pathfinding for future node extensions, not first-gen |

Foundational Technology

Based on IBM 2nm Research Platform

-

Developed originally by IBM Research Albany (announced in 2021).

-

First public demonstration of stacked nanosheets with 12nm gate length.

-

Rapidus licensed IBM’s device architecture, process flow, and DTCO methodology.

imec Collaboration

-

Supports process integration, mask development, and material modeling through imec’s platform in Leuven, Belgium.

Timeline

| Year | Milestone |

|---|---|

| 2021 | IBM announces 2nm GAA prototype |

| 2022 | Rapidus founded and licenses IBM 2nm tech |

| 2023 | Construction of Chitose R&D fab begins |

| 2024 | EUV tools ordered, pathfinding with imec begins |

| 2025 | Pilot line operational in Hokkaido |

| 2026 | Process qualification |

| 2027 | Volume production of 2nm logic devices begins |

Technical Architecture

Gate-All-Around (GAA) Nanosheet

-

Multi-Bridge Channel FET structure: several nanosheets stacked vertically and fully surrounded by a gate.

-

Offers improved electrostatic control, lower leakage current, and greater scalability than FinFET.

-

Sheet width modulation enables tuning of performance and leakage tradeoffs.

Interconnect

-

EUV patterning with 1D gridded interconnects for tighter pitch.

-

Advanced middle-of-line process integration for signal routing.

Device Design Targets

| Metric | Target |

|---|---|

| Gate pitch | ~42nm |

| Metal pitch | ~28nm |

| Effective transistor density | >300 million/mm² |

| Supply voltage | ~0.6–0.75V |

| Frequency scaling | >4GHz design feasibility |

Applications

The Rapidus 2nm node is being designed for:

-

AI accelerators

-

High-Performance CPUs & GPUs

-

Automotive SoCs (ASIL-D target)

-

5G/6G and edge compute

-

Low-power mobile/embedded systems

Competitive Landscape

| Company | Node | Target Year |

|---|---|---|

| TSMC | N2 | 2025–2026 (risk prod), 2026–2027 (HVM) |

| Intel | Intel 20A / 18A | 2024 (pre-2nm, ribbonFET) |

| Samsung | SF2 / SF1.4 | 2025+ |

| Rapidus | 2nm | 2027 |

Although Rapidus trails TSMC and Samsung by 1–2 years in ramp, it is targeting a “leapfrog” approach through ecosystem co-development and tight design-technology co-optimization (DTCO) with global partners.

Challenges

| Area | Details |

|---|---|

| Workforce | Recruiting and training engineers for GAA and EUV is ongoing |

| Ecosystem | Japan lacks native EDA, IP, and 2nm tapeout flow vendors |

| Yield Ramp | High defect sensitivity due to small feature sizes |

| Capital Investment | 2nm fabs cost $15–20B; needs sustained government support |

Government Support

-

Supported by METI (Ministry of Economy, Trade and Industry)

-

Expected $5–10 billion in subsidies over multiple years

-

Aligned with Japan’s economic security and semiconductor sovereignty initiatives

Summary

The Rapidus 2nm process represents a bold national effort by Japan to re-enter the top tier of semiconductor manufacturing. With IBM’s GAA nanosheet platform, imec collaboration, and Japanese industrial strength, Rapidus seeks to become a trusted, high-performance foundry for advanced AI and compute semiconductors in the post-FinFET era.

Also Read:

Share this post via:

A Century of Miracles: From the FET’s Inception to the Horizons Ahead