Chip-on-Wafer-on-PCB (CoWoPCB) is a heterogeneous integration flow in which bare dies (“chips”) are first assembled and interconnected at wafer scale (on an interposer or fan-out carrier). The completed wafer-level module is then finished with board-pitch I/O and mounted directly to a printed circuit board (PCB)—eliminating the traditional package substrate. The goal is to combine wafer-level density and short interconnects with PCB-level cost, area, and system modularity.

Typical targets include AI accelerator cards, networking line cards, high-bandwidth storage controllers, RF front-ends, and compact embedded compute modules where z-height, latency, and cost per function are critical.

Why CoWoPCB?

-

Substrate removal: Skips the package substrate to cut cost and stack height while reducing thermal interfaces.

-

Wafer-level density: Chiplets, SRAM tiles, and HBM/base dies can be joined at fine pitch (micro-bump or hybrid bond).

-

Board-level modularity: The module becomes a directly solderable (or socketable) “system brick,” simplifying mechanics and inventory.

-

Latency & power: Shorter interconnects from logic↔memory and logic↔I/O reduce RC delay and I/O power.

Architecture & Building Blocks

-

Wafer-level carrier

-

Silicon interposer with TSVs for extreme wiring density and skew control.

-

Fan-out RDL-on-wafer (TSV-less) for low z-height and cost efficiency.

-

Glass wafer carriers (emerging) for improved dimensional stability and low loss; TGVs optional.

-

-

Die attach & interconnect

-

Micro-bump pitches from ~45 μm trending to ≤20 μm; hybrid bonding ≤10 μm for ultra-low resistance/capacitance.

-

-

Board-pitch interface

-

Wafer-side RDL hierarchy that fans out from micron-scale wiring to BGA/LGA suitable for PCB assembly (e.g., 0.5–1.0 mm ball pitch, design-dependent).

-

Underfill, corner staking, or compliant interposers for solder-joint reliability.

-

-

Thermo-mechanical elements

-

Stiffeners/frames, lids, vapor chambers or cold plates; optional cavity PCBs for co-planarity and z-height control.

-

Representative Process Flow

-

Carrier fabrication (wafer level): Build TSV/TGV (if used), multilayer RDL, and UBM on silicon/glass/fan-out carrier.

-

Chip attach (wafer level): Place logic tiles, HBM stacks (or HBM base dies), analog/RF chiplets; micro-bump or hybrid bond; apply NCF/MUF; cure and clean.

-

Wafer thinning & finish: Back-grind/polish; add backside RDL/PDN; probe for known-good-module where feasible.

-

Board-pitch I/O formation: Build bump/land arrays (BGA/LGA) and protective structures on the wafer module’s underside to meet PCB assembly rules.

-

Singulation: Dice the wafer into modules; add lids/stiffeners/thermal hardware as required.

-

Board assembly: SMT attach module directly to PCB; underfill/stake as needed; attach heat spreaders/cold plates; system-level test.

Flows may be “chip-first” or “RDL-first,” and board attach can be solder reflow, thermocompression with adhesives/films, or LGA + compression frame.

Design & Integration Considerations

-

PDN co-design: Stack-up must bridge wafer planes to PCB planes with low inductance paths; consider hierarchical decoupling (on-wafer MIM, interposer planes, board VRM proximity).

-

Signal integrity: Ultra-wide HBM buses and die-to-die fabrics demand controlled impedance, short stubs, back-drilled vias, and low-loss board dielectrics.

-

Thermals: High-TDP modules (>300 W possible) require direct-attach lids, high-k TIMs, and board-level cooling hardware. Thermal gradients drive mechanical stress—simulate early.

-

CTE mismatch: Silicon ↔ FR-4/low-CTE laminates need compliant joints, underfill, and symmetric build-ups to manage fatigue and warpage.

-

Test strategy: Invest in KGD; add wafer-module test pads and PCB boundary-scan/JTAG access; plan for system-in-test (SiT) vectors and on-board monitors.

Variants You’ll Hear About

-

CoWoPCB-Si: Silicon interposer at wafer level, direct BGA to PCB. Max density and performance.

-

CoWoPCB-RDL: TSV-less fan-out carrier; thinnest z-height, attractive cost/performance.

-

CoWoPCB-Glass: Glass carrier and/or glass-core PCB for flatness and low loss (ecosystem maturing).

-

Cavity CoWoPCB: Module recessed into a PCB cavity for mechanical support and lower profile.

-

Socketed CoWoPCB: LGA compression or mezzanine connector for field-replaceable modules.

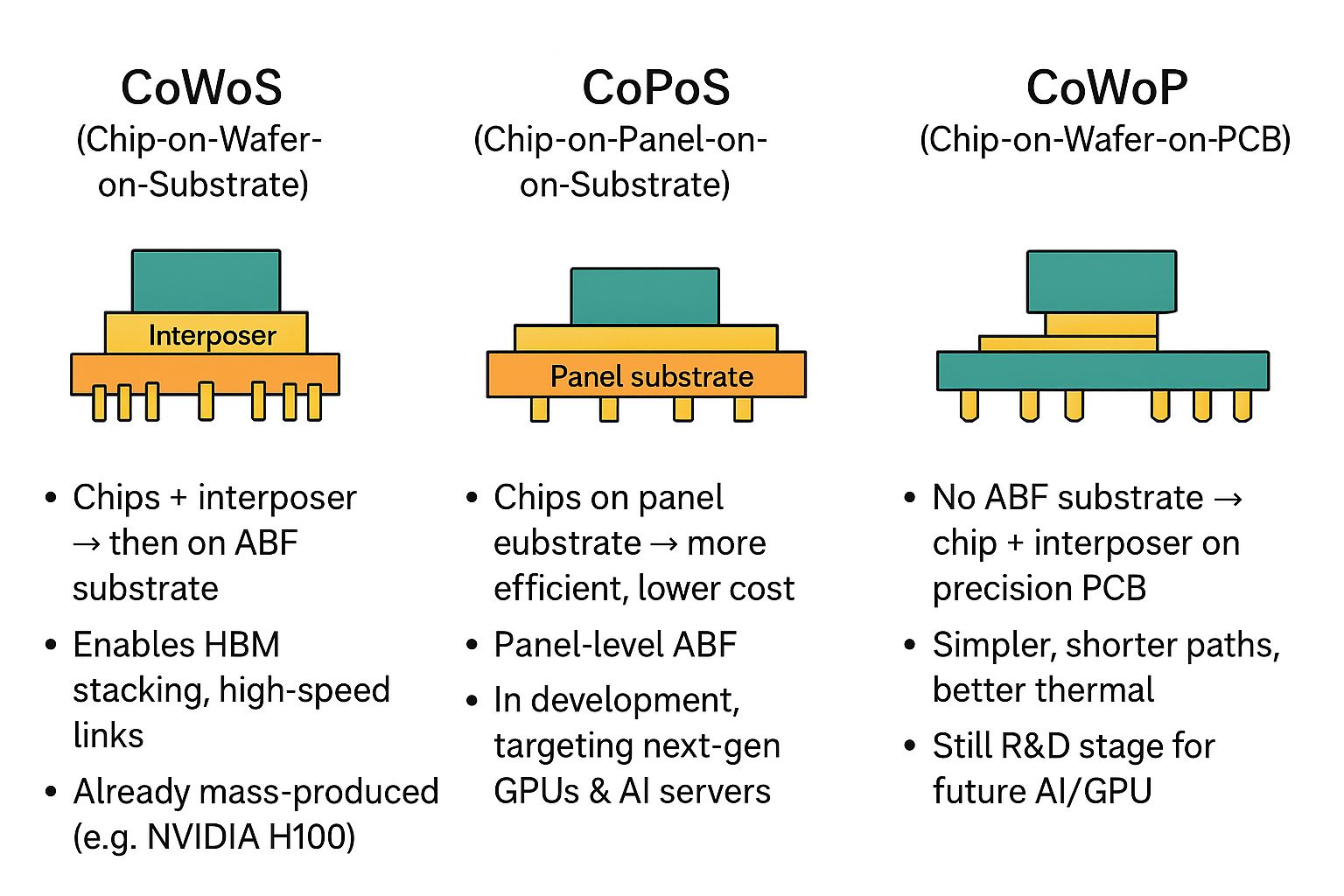

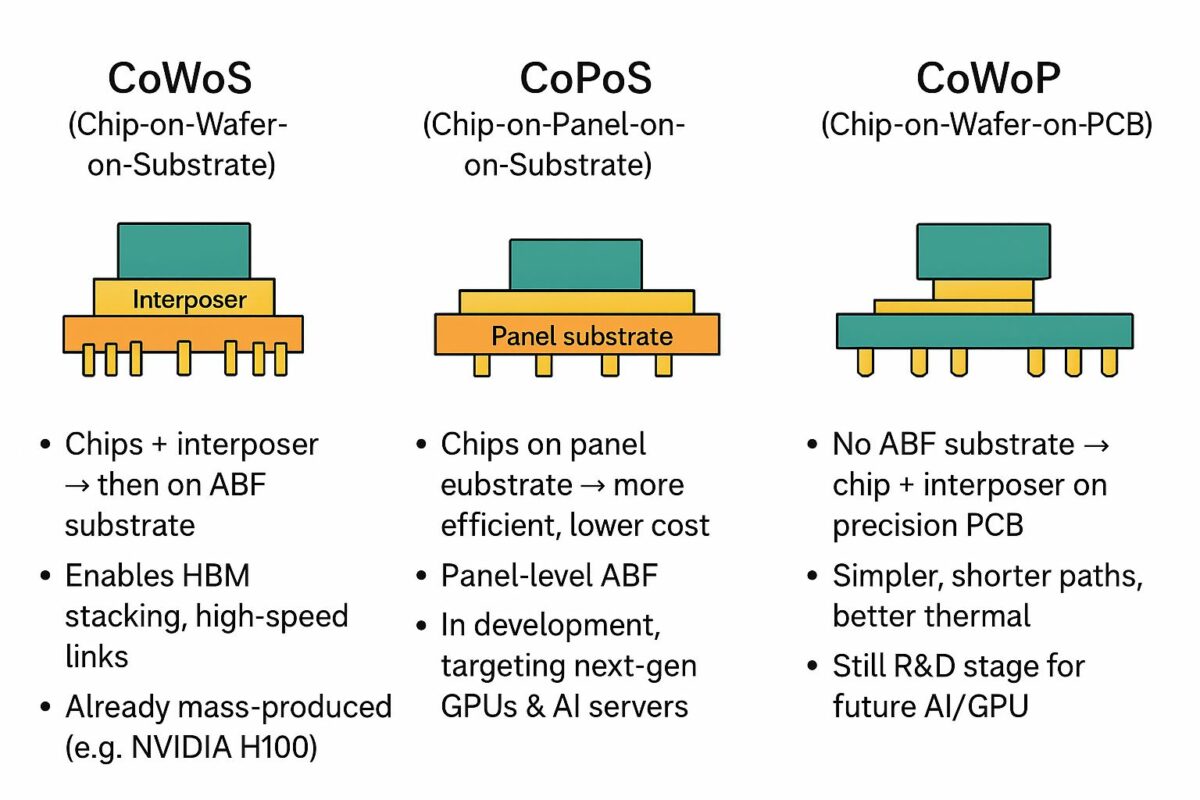

CoWoPCB vs. Other Approaches (quick take)

-

vs CoWoS: Removes the package substrate; relies on wafer-side fan-out to reach board pitch, trading some routing freedom for lower cost/z-height.

-

vs Fan-Out Panel-Level Packaging (FO-PLP): FO-PLP embeds dies in mold on a panel; CoWoPCB leverages wafer-level precision and then goes straight to PCB, benefiting modules that need extreme intra-module density.

-

vs EMIB/bridge substrates: Bridges excel inside a package substrate; CoWoPCB externalizes the module to the PCB, simplifying system assembly at the expense of some substrate-level routing options.

-

vs Package-on-Package (PoP) / SiP: CoWoPCB targets board integration directly, favoring large, high-power modules and aggressive thermals.

Prime Use Cases

-

AI/HPC accelerator modules: Multi-tile logic + 6–12× HBM with short, dense channels and board-level cooling.

-

Switch/Router ASICs: High-lane-count SerDes, co-packaged optics adjacency on the board.

-

Edge/embedded compute: Thin modules in cavity PCBs for robotics, avionics, and telecom.

-

RF/mixed-signal front-ends: Short path to antennas/filters on the board while keeping analog dies close together on wafer.

Manufacturing & Ecosystem

-

Foundry/OSAT alignment: Interposer and wafer-level assembly must align with PCB fab/assembly DFM, including stencil, paste, profile, and co-planarity specs.

-

PCB partners: Low-loss, high-Tg, low-CTE laminates; blind/buried vias, via-in-pad and back-drill capability; tight impedance control.

-

Equipment & materials: Large-format bonders, precise warpage control fixtures, robust underfills, high-reliability solder alloys, advanced TIMs and lids.

Key Challenges

-

Board-level reliability: Solder-joint fatigue under thermal cycling and vibration; mitigated via underfill, corner staking, and compliant interposers.

-

Warpage budgets: Module flatness across reflow; manage through symmetric build-ups, frames, cavity boards, and tuned profiles.

-

I/O fan-out: Bridging from ≤10 μm wafer wiring to 500–1000 μm board pitch without crosstalk or IR drop penalties.

-

Reworkability: Direct-attach modules are harder to rework than socketed cards; design service strategies accordingly.

-

Test coverage: Ensuring high coverage before permanent board attach; plan for board-level diagnostics and field telemetry.

Roadmap & Metrics to Watch

-

Hybrid-bond adoption: Moving chiplet and memory base-die joins to ≤10 μm mainstream.

-

RDL scaling: Stable 1–2 μm L/S on wafer carriers plus robust board-pitch transition stacks.

-

Low-CTE boards: Wider availability of low-CTE glass/organic cores to reduce solder strain.

-

Thermal density: Module-level heat flux targets and standardization of liquid-cool plate interfaces.

-

Yield orchestration: Known-good-die, known-good-module, and board-level screening to control compounded yield loss.

Practical Design Tips

-

Partition chiplets to keep the noisiest fabrics closest and shortest; isolate analog/RF islands with guard structures at the wafer level.

-

Use hierarchical PDN: on-wafer MIM caps, interposer planes, then thick board planes with local VRMs.

-

Add sacrificial test pads on the wafer module and boundary-scan hooks on the PCB for bring-up and field debug.

-

Co-design thermals and mechanics early: lid selection, clamp points, cavity depth, and keep-outs for cold-plate plumbing.

-

Specify board fab rules that match your BGA escape and back-drill assumptions; validate in 3D EM/thermal-mechanical sims.

Notable Quotes (unattributed)

-

“If you can wire it at wafer pitch and land it at board pitch, you’ve built a bridge from physics to economics.”

-

“CoWoPCB turns packaging into a system module, not just a protective shell.”

-

“Eliminate the substrate and you remove a cost layer and a thermal interface—but only if reliability keeps up.”

-

“Board attach makes test strategy a first-class citizen; what you don’t catch before reflow becomes a field problem.”

-

“In the chiplet era, PDN integrity is the new floorplan.”

-

“Glass brings flatness; design brings yield.”

-

“Short wires save watts; good mechanics save products.”

Glossary

-

Interposer: Dense wiring layer (often silicon) that connects multiple chiplets at fine pitch; may use TSVs.

-

RDL (Redistribution Layer): Thin-film metallization that reroutes I/O to different pitches/locations.

-

Hybrid Bonding: Cu-to-Cu and dielectric direct bonding enabling ultra-fine pitch interconnects with low resistance.

-

BGA/LGA: Ball-grid or land-grid array interfaces suitable for standard PCB assembly or compression sockets.

-

CTE (Coefficient of Thermal Expansion): Mismatch between materials that drives stress during temperature changes.

-

Cavity PCB: Board with a recessed pocket to host a module, improving planarity and reducing z-height.

Also Read:

Share this post via:

A Century of Miracles: From the FET’s Inception to the Horizons Ahead