Teenes

New member

Traditional manual inspections and conventional AOIs often face challenges like inefficiency, human error, and limited adaptability. The ViTrox V9i Advanced Robotic Vision (ARV) Solution addresses these issues by automating vision inspection tasks with unparalleled precision and reliability.

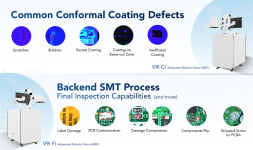

The V9i ARV Solution features a cutting-edge vision module mounted on a 6-axis COBOT robotic arm, enabling flexible 2D and 3D multi-angle inspections up to 90°. Its Advanced Smart Learning Algorithm excels at detecting defects in conformal coatings, screws, cosmetics, connectors, and labels—without requiring CAD data. Supporting PCB sizes up to 840mm x 620mm, the V9i ARV XL variant handles even larger boards, offering unmatched versatility.

Engineered for efficiency, the system boosts throughput by up to 200% compared to manual inspections, providing high-resolution images with clarity down to 14µm/px. It operates 24/7, ensuring consistent, cost-effective results while seamlessly integrating into production lines via SMEMA connectivity and Industry 4.0-ready solutions like ViTrox’s V-ONE platform.

Ideal for industries including automotive, aerospace, telecommunications, and industrial manufacturing, the V9i ARV Solution is a game-changer in quality control. Discover how this innovation enhances inspection efficiency, consistency, and scalability for your production line. Get specified details on this excellent machine over here. For official inquiries to get your hands on the machine, you may visit us at Vitrox or drop an email to enquiry@vitrox.com

The V9i ARV Solution features a cutting-edge vision module mounted on a 6-axis COBOT robotic arm, enabling flexible 2D and 3D multi-angle inspections up to 90°. Its Advanced Smart Learning Algorithm excels at detecting defects in conformal coatings, screws, cosmetics, connectors, and labels—without requiring CAD data. Supporting PCB sizes up to 840mm x 620mm, the V9i ARV XL variant handles even larger boards, offering unmatched versatility.

Engineered for efficiency, the system boosts throughput by up to 200% compared to manual inspections, providing high-resolution images with clarity down to 14µm/px. It operates 24/7, ensuring consistent, cost-effective results while seamlessly integrating into production lines via SMEMA connectivity and Industry 4.0-ready solutions like ViTrox’s V-ONE platform.

Ideal for industries including automotive, aerospace, telecommunications, and industrial manufacturing, the V9i ARV Solution is a game-changer in quality control. Discover how this innovation enhances inspection efficiency, consistency, and scalability for your production line. Get specified details on this excellent machine over here. For official inquiries to get your hands on the machine, you may visit us at Vitrox or drop an email to enquiry@vitrox.com