Jennifer, an OEM hardware designer, is planning a product around a microcontroller she thinks will meet her needs and wants to supply power from a 3V coin cell battery which she must connect though a boost controller. Jennifer searches a rough description of the part she needs, generating a long list of component manufacturers who are all anxious to attract her attention. She clicks through the websites, scans the headlines and tries to drill down through white papers and technical datasheets. She ends her day with a headache and still no clear idea of who would be the best fit since tradeoffs in how she builds her design depend on component details that are difficult to extract from multiple dense PDFs.

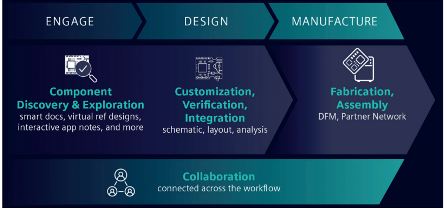

Suppose instead she started her parts search along a path designed to guide her painlessly to a decision. She can do all the discovery she wants without having to leave her terminal, without needing to read through lengthy datasheets, or committing to a purchase. She can experiment with interactive reference designs, exploring parameter changes that will more closely match her needs. At every step Jennifer becomes more confident that she has found the right component to fit her objectives. This component manufacturer is on track for a design win before sales ever picks up a phone, and she will be drawn naturally to look for her next component from the same supplier.

Redesigning initial component discovery for the OEM engineer

Nobody wants to wade through datasheets and technical specs in the early stages of discovery. This is the age of AI and chatbots. We should be able to ask natural language questions about configurations and operating parameters and expect to get helpful answers — more detailed answers than are available through a generic GPT-like search.

This more effective search might narrow the field perhaps to a couple of options. Our engineer now wants to experiment with the component she thinks might be the best fit, but without having to get into detailed eCAD yet. The manufacturer offers an interactive reference design in which she can experiment with parameters, maybe battery voltage and internal resistance, and directly view impact on behavior, say for load current draw.

The manufacturer also offers exploration tools to view schematics, PCB layout, and BOM for the reference design so she can develop a sense of how this may translate to her product objectives. At the same time, she can check availability, supply chain issues, and regional compliance issues, minimizing time wasted on manufacturing mismatches and forestalling any late-stage manufacturing surprises.

A Siemens white paper has an interesting way of describing this interaction. Unlike traditional marketing-centric web pages and PDFs, this is engineering outreach, not marketing outreach.

Now that she is committed to this path, Jennifer can transition her trial experiments into full eCAD development around her design, through a natively supported tool suite accessible through this interactive design enablement flow or through a preferred in-house flow supported by direct eCAD model downloads based on the parts she’s selected — while continuing to keep an eye on potential manufacturing hiccups as geopolitical realities evolve.

Collaboration, enhancing manufacturer stickiness

Jennifer may have questions which can’t be answered through AI searches or interactive references. Collaborative discussion with an expert application engineer can guide her through these concerns. With permission, the apps experts can review detailed and more open-ended questions in the context of a design example and suggest possibilities through markup, comments or examples — without the need to schedule meetings.

This interaction has obvious benefits both for the designer and for the component manufacturer. The designer has a simple glide path to component selection using the language she speaks: natural language filters, trials against an interactive reference design and schematic and PCB layout to confirm the fit to her objective. The manufacturer gets a prospect already invested in how their components fit her solution without the overhead of meetings. Everyone wins.

Does this vision sound appealing? Read this Siemens white paper for a more detailed understanding of how they have enabled this solution together with Microchip as a component manufacturer.

Also Read:

AI-Driven DRC Productivity Optimization: Revolutionizing Semiconductor Design

Visualizing hidden parasitic effects in advanced IC design

Protect against ESD by ensuring latch-up guard rings

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.