Overview

TSMC N3 is the 3-nanometer FinFET semiconductor manufacturing node developed by Taiwan Semiconductor Manufacturing Company (TSMC). It is a major milestone in TSMC’s process technology roadmap and represents the first step into the 3nm era, succeeding the N5 and N4 nodes.

Unlike Samsung, which introduced Gate-All-Around (GAA) technology with its 3nm, TSMC continues to use FinFET transistors at the N3 generation. GAA will debut in TSMC’s N2 (2nm) node, expected in late 2025.

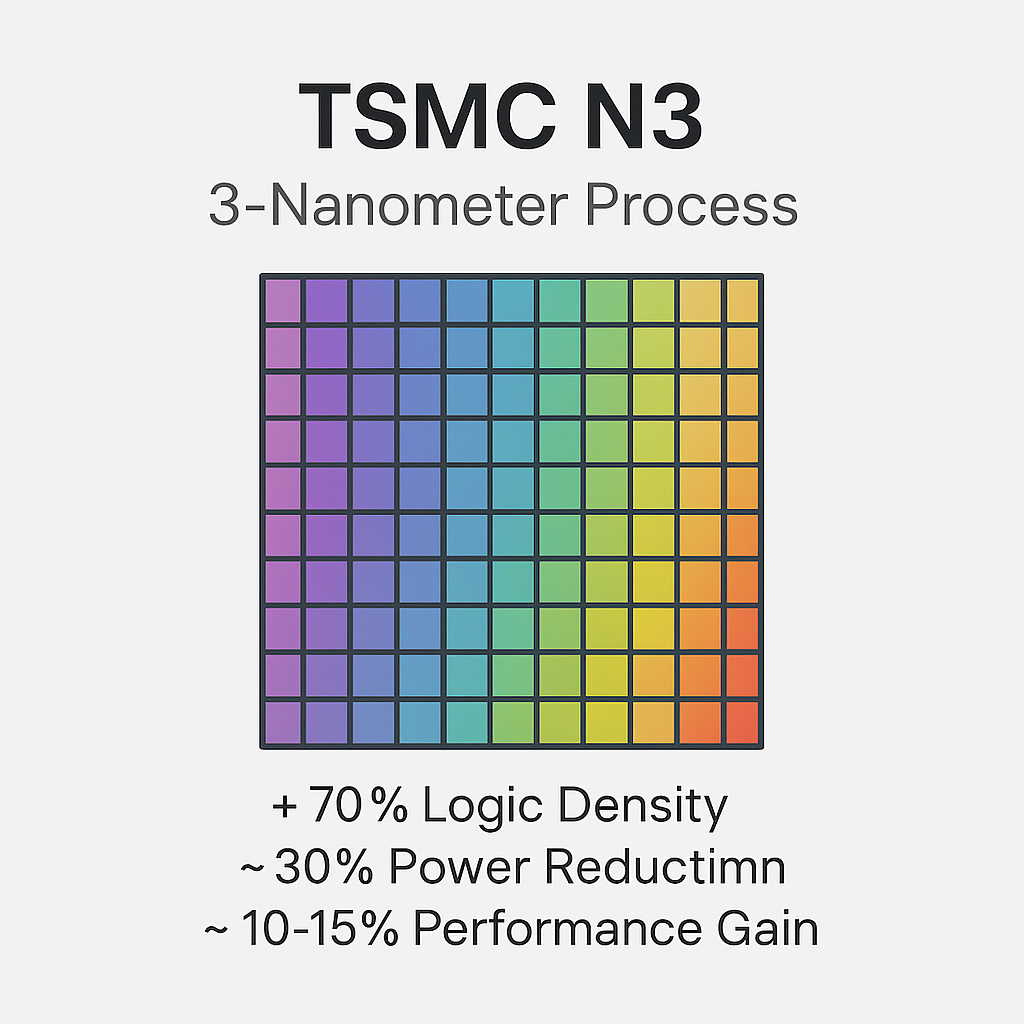

Technical Highlights

| Feature | TSMC N3 (N3B Baseline) | Compared to N5 |

|---|---|---|

| Transistor Type | FinFET | — |

| Density Increase | +70% logic density | vs. N5 |

| Power Consumption | ~30% lower | at same speed |

| Performance | ~10–15% faster | at same power |

| EUV Layers | ~25–28 EUV layers | vs. ~14 in N5 |

| Gate Pitch Shrink | Tightened metal and poly pitch | Enables higher density |

| SRAM Cell Size | ~5–10% smaller | vs. N5 |

| BEOL Scaling | Advanced multi-patterned metallization | More RC delay optimized |

SRAM Comparison: TSMC N3 vs. N5

| Feature | TSMC N5 | TSMC N3 (N3B) | TSMC N3E |

|---|---|---|---|

| SRAM Bitcell Size | ~0.021 µm² | ~0.0199 µm² | ~0.021 µm² |

| Area Scaling | – | ~5–10% smaller vs. N5 | Roughly same as N5 |

| Performance | Mature, good Vmin behavior | Lower Vmin, but more variability | Improved stability vs. N3B |

| Leakage Power | Baseline | Slightly higher | Lower than N3B |

| Yield | High | Lower for SRAM than logic | Better than N3B, but not as strong as N5 |

Process Notes:

-

N3B is not IP-compatible with N5/N4, unlike N3E.

-

Contacted poly pitch (CPP) and metal pitch were both aggressively scaled.

-

Still uses DUV + EUV lithography, but with significantly more EUV steps than N5.

-

Introduces tighter layout design rules, requiring extensive PPA co-optimization.

N3 Platform Variants

TSMC has extended the N3 platform into multiple specialized versions:

| Variant | Description | Key Features |

|---|---|---|

| N3B | Baseline node, used by Apple first | Most EUV layers, higher density, lower yield |

| N3E | Enhanced version, mass-market ready | Lower cost, better yield, improved performance |

| N3P | Performance-focused N3E derivative | Targeted at HPC and AI SoCs |

| N3X | High-performance extension | For ultra-high-performance computing |

| N3AE | Automotive-grade N3E (planned) | For ADAS and vehicle processors |

Manufacturing & Supply Chain

-

Main Fab: Fab 18, Tainan, Taiwan

-

Risk Production Start: Q3 2021 (N3B)

-

Volume Production (N3B): Late 2022 (limited customers)

-

Volume Production (N3E): Late 2023 onward

-

Geographic Expansion:

-

N3 not expected to be deployed at Arizona Fab 21 (focused on N4/N5).

-

N3/N2 to remain in Taiwan due to fab complexity and talent concentration.

-

Real-World Adoption

🔹 Apple

-

A17 Pro (iPhone 15 Pro/Pro Max) — First mass-produced chip on N3B

-

M3 Series (M3, M3 Pro, M3 Max, M3 Ultra) — 2023–2024 Mac chips on N3B/N3E

-

M4 Series — 2024–2025 on N3E

🔹 Other Expected Customers

| Company | Notes |

|---|---|

| Intel | Planning to use N3E/N3P for chiplets in upcoming CPUs and SoCs |

| AMD | Expected to move GPU and CPU chiplets to N3P in 2025–2026 |

| MediaTek | Flagship Dimensity SoCs on N3E starting in 2024 |

| Qualcomm | Evaluating N3P/N3X; may stay on N4/N5 until mid-2025 |

| Broadcom, Marvell, NVIDIA | Targeting N3E and N3X for networking, AI accelerators, and HPC |

Challenges and Lessons from N3B

TSMC’s N3B was more aggressive in design and less optimized for yield, leading to:

-

High defect rates initially, making it viable only for large-volume, high-margin customers like Apple.

-

Reluctance from other chipmakers to adopt until N3E.

TSMC acknowledged this by pivoting future customers toward N3E, which:

-

Has better performance-per-watt

-

Lower manufacturing cost per wafer

-

Is design-rule compatible with future N3 derivatives (P, X, AE)

EDA & IP Ecosystem

-

Full PDK (Process Design Kit) support from:

-

Cadence (Innovus, Spectre)

-

Synopsys (Fusion Compiler, PrimeTime)

-

Ansys (RedHawk, Totem)

-

-

IP library vendors providing:

-

Standard cell libraries

-

SRAM compilers

-

Interface IP (DDR5, LPDDR5, PCIe 5.0/6.0, USB4, CXL)

-

TSMC also expanded its Open Innovation Platform (OIP) to support early tapeouts and test chips from partners on N3E.

Roadmap: N3 to N2 and Beyond

| Node | Year | Key Change |

|---|---|---|

| N3B | 2022 | First-generation 3nm, high EUV |

| N3E | 2023 | Enhanced node, better yield |

| N3P | 2024 | Performance-focused N3E |

| N3X | 2025 | High-performance for AI/HPC |

| N2 | Late 2025 (risk), 2026 (volume) | GAA (Nanosheet) + Backside Power Delivery |

-

N2 will be TSMC’s first nanosheet (gate-all-around) node.

-

Introduces backside power delivery network (BSPDN) for power integrity and IR drop reduction.

Comparison With Competitors

| Company | Node | Type | Notes |

|---|---|---|---|

| TSMC | N3B/N3E | FinFET | Most mature, Apple-exclusive early |

| Samsung | SF3E/SF3 | GAA | First to market with GAA, but lower yield/adoption |

| Intel | Intel 3 | FinFET | Matches TSMC N5/N3E in performance; used for internal and foundry clients |

Advancing Automotive Memory: Development of an 8nm 128Mb Embedded STT-MRAM with Sub-ppm Reliability