Also known as: TSMC 1.4nm, A14 process node

Node class: Advanced logic technology (1.4nm)

Foundry: Taiwan Semiconductor Manufacturing Company (TSMC)

Expected HVM (High Volume Manufacturing): 2028

Predecessor: TSMC N2 (2nm)

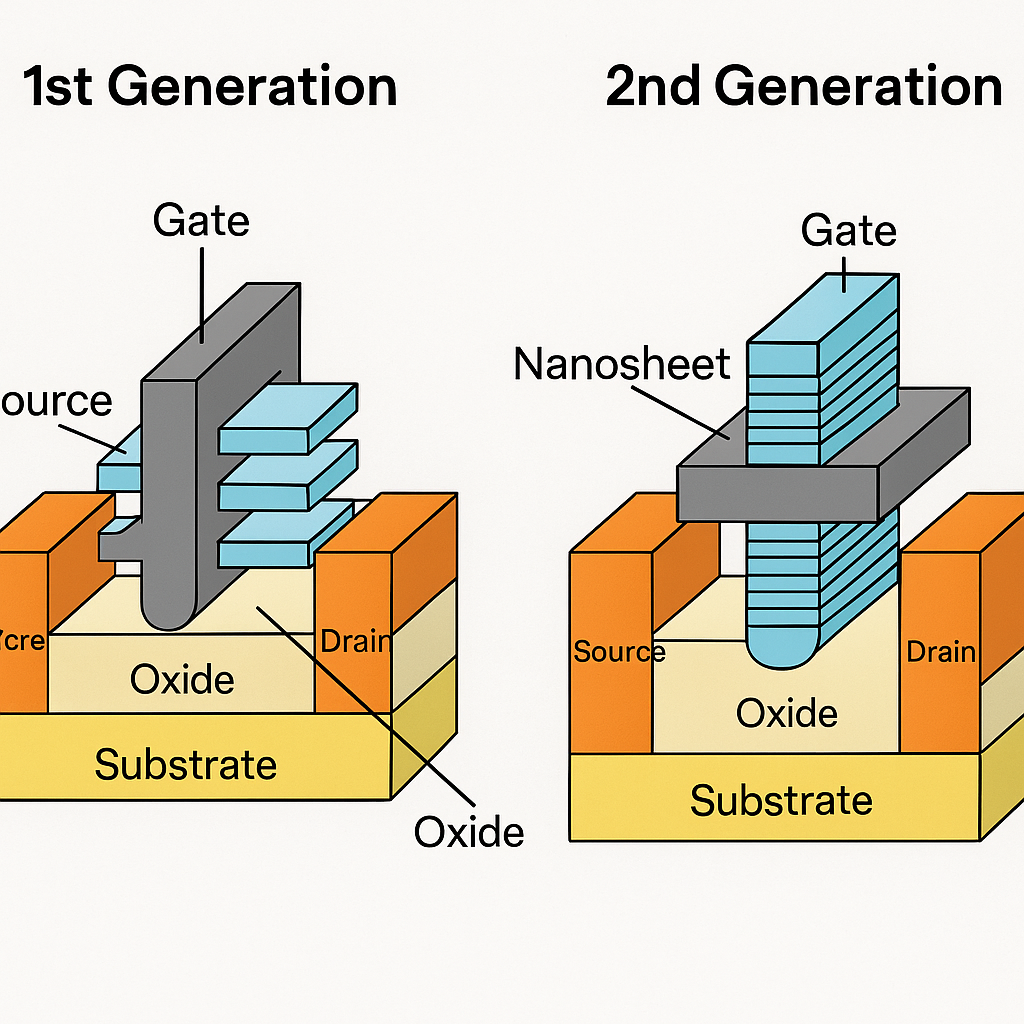

Transistor architecture: 2nd Generation GAAFET (nanosheet)

Backside power variant: A14P (planned for 2029)

Overview

TSMC A14 is the company’s next full-node technology after TSMC N2, representing a significant leap in logic transistor density, power efficiency, and performance. It is built using second-generation Gate-All-Around Field-Effect Transistors (GAAFETs) and is co-optimized with TSMC’s NanoFlex™ Pro architecture to support flexible transistor design across power, performance, and area trade-offs.

Unlike many industry expectations, TSMC will not use High-NA EUV lithography for A14; instead, it continues leveraging its current EUV technology with innovative patterning techniques, thereby reducing cost and complexity.

Process Technology Features

| Feature | Description |

|---|---|

| Node Class | Full node advancement from N2 |

| Transistor Type | 2nd-generation GAAFET (stacked nanosheet) |

| Gate Control | Improved electrostatics over N2; better subthreshold leakage and drive current |

| Lithography | Conventional EUV with advanced multi-patterning |

| NanoFlex Pro Support | Enables per-block transistor width optimization |

| Backside Power (SPR) | Not in base A14; added in A14P variant (2029) |

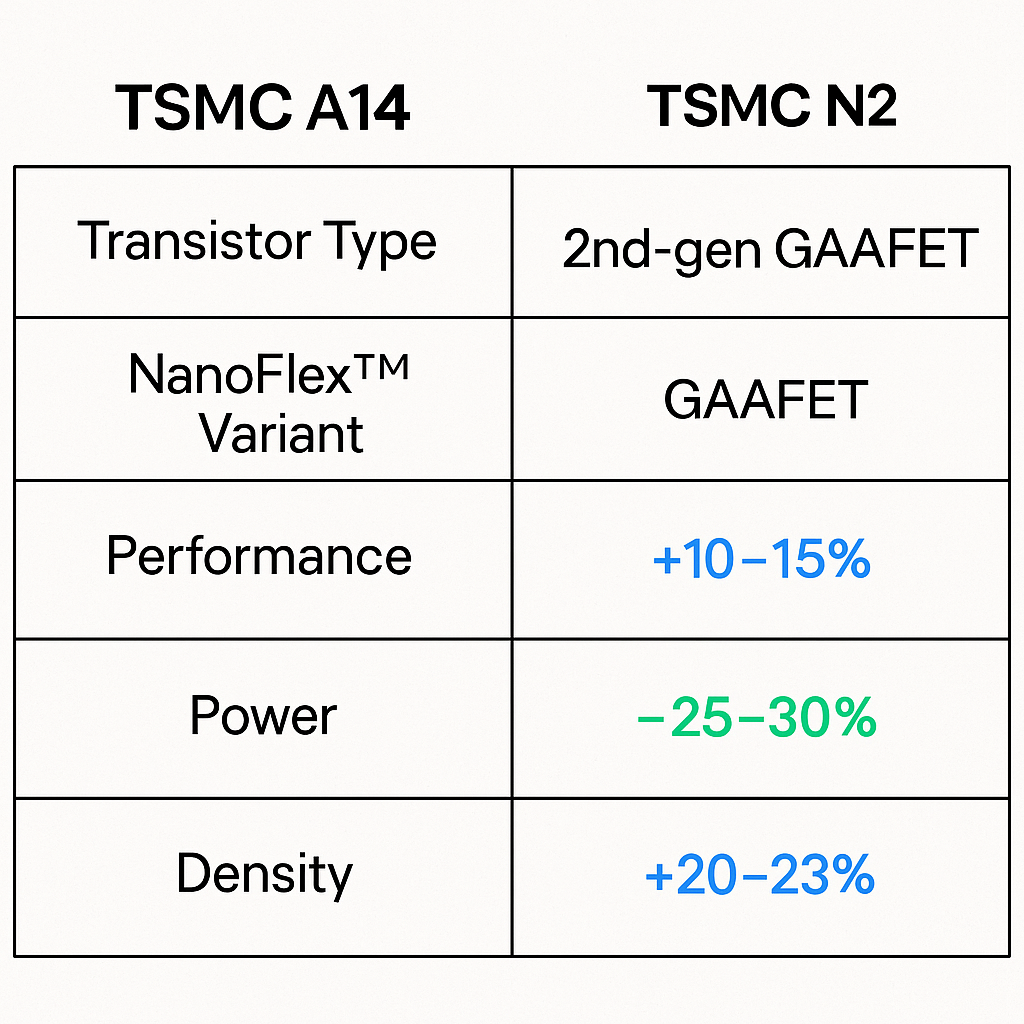

Performance, Power, and Density (PPA)

Compared to TSMC N2, the A14 node delivers:

-

+10–15% performance gain at the same power

-

– 25–30% power reduction at the same speed

-

+20–23% logic density improvement

These improvements reflect a full node advancement, unlike the intra-node optimizations (e.g., N3E → N3P) seen in previous generations.

Architectural Innovations

◾ 2nd-Gen GAAFETs

TSMC’s A14 transistors benefit from refinements in channel control and nanosheet stacking, allowing tighter pitches, higher drive current, and better leakage characteristics.

◾ NanoFlex™ Pro

An advanced evolution of the original NanoFlex technology used in N2, NanoFlex Pro enables finer-grained transistor width tuning. Designers can choose wider nanosheets for high performance or narrower ones for power efficiency—block by block.

◾ EUV Strategy

TSMC is not adopting High-NA EUV for A14. Instead, it pushes standard NA EUV with more mature multi-patterning and alignment schemes, reducing capital cost and design risk.

Design Ecosystem and IP Readiness

-

EDA and IP partners (Arm, Synopsys, Cadence, etc.) are expected to tape out IP platforms starting 2027.

-

AI accelerators, HPC SoCs, and advanced chiplets will be first to adopt the A14 node.

-

A14 will support 3DIC and chiplet architectures via CoWoS, InFO, and SoIC.

Timeline

| Year | Milestone |

|---|---|

| 2023–24 | A14 announced during TSMC Technology Symposium |

| 2026 | N2P/N2X in production, used as A14 design base |

| 2027 | A14 risk production begins |

| 2028 | A14 enters high-volume manufacturing (HVM) |

| 2029 | A14P variant with backside power delivery (SPR) launches |

Strategic Impact

Industry Leadership

A14 keeps TSMC in the lead for logic process scaling. While Intel plans to introduce 18A (2nm-class) and eventually move to High-NA EUV, TSMC’s more measured approach leverages tool maturity over radical equipment shifts, enabling cost-effective ramp.

AI and HPC Readiness

TSMC positions A14 for AI accelerators, datacenter CPUs, and chiplets, where power density and bandwidth are critical.

Chiplet Integration

A14 will be a key enabler for heterogeneous integration, allowing multiple dies (different nodes and functions) to interconnect with advanced 2.5D/3D packaging.

Beyond A14

TSMC is actively exploring Forksheet FETs and Complementary FETs (CFETs) for post-A14 nodes (e.g., A10 or 1.0nm-class). These may introduce vertical stacking of N- and P-type devices or integration with optical and neuromorphic systems.

Summary

| Feature | TSMC A14 |

|---|---|

| Node Size | ~1.4nm (naming) |

| Transistor Type | 2nd-gen GAAFET |

| Density Gain | +20–23% over N2 |

| Power Reduction | –25–30% |

| Performance Gain | +10–15% |

| EUV Type | Standard NA |

| Backside Power | A14P (2029) |

| High-NA EUV | Not required |

| Volume Production | 2028 |

The Name Changes but the Vision Remains the Same – ESD Alliance Through the Years