Full Name: High Numerical Aperture Extreme Ultraviolet Lithography

Abbreviation: High-NA EUV

Technology Type: Advanced semiconductor photolithography

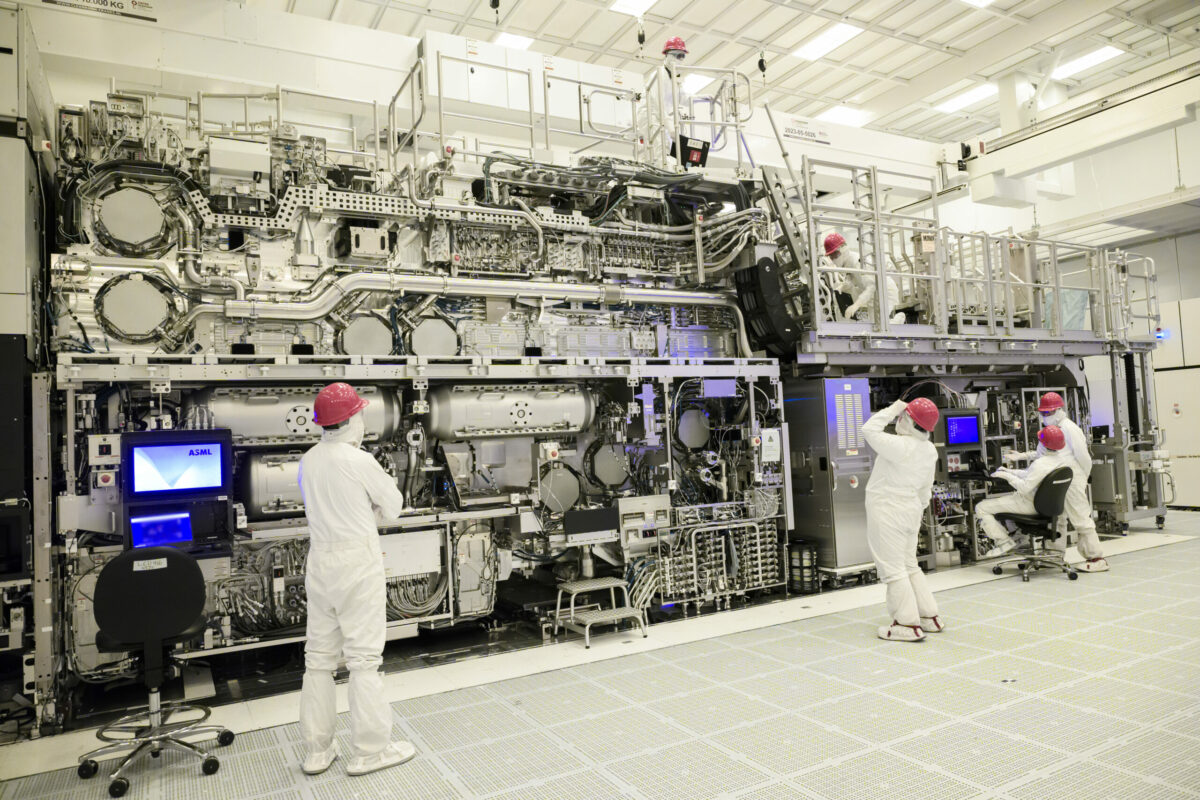

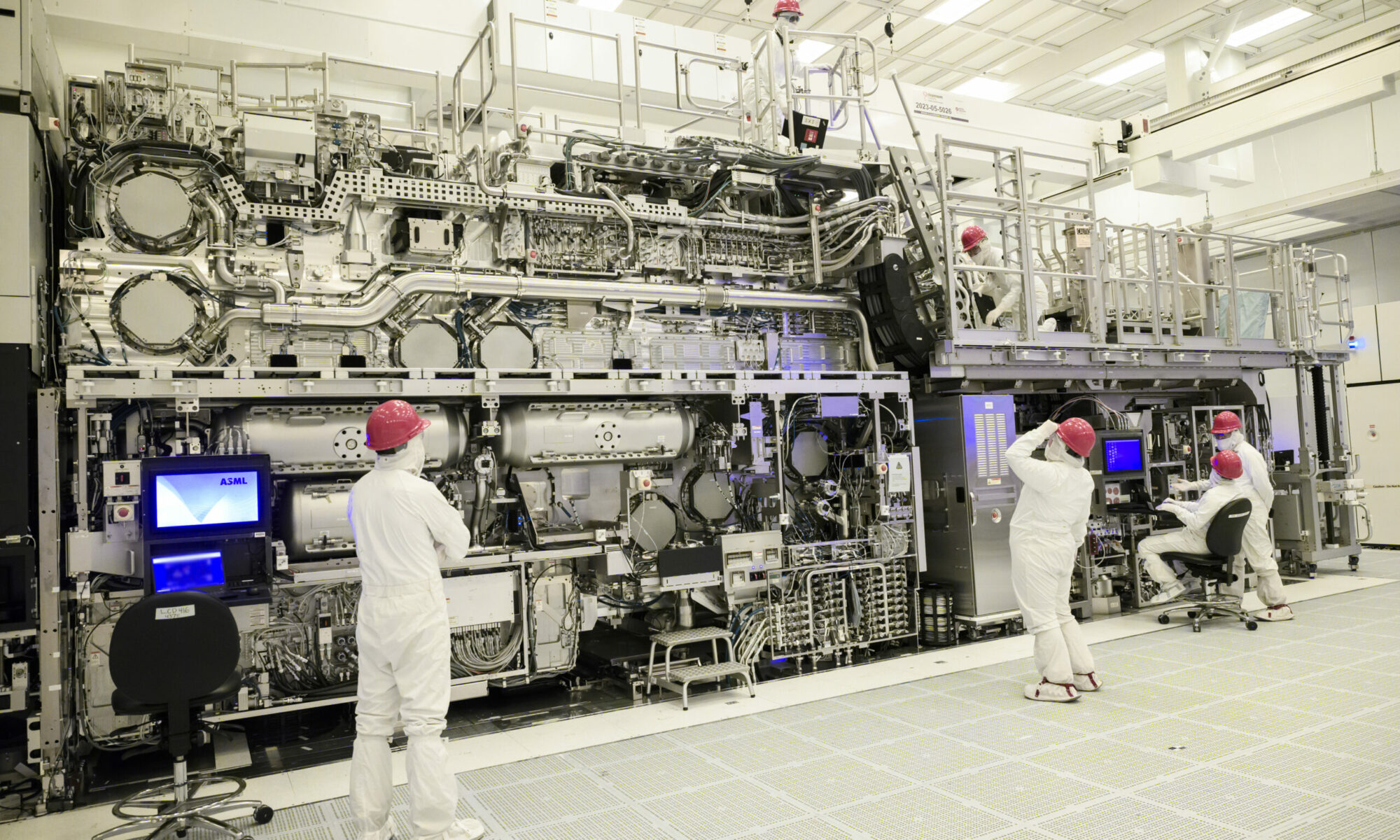

Developed By: ASML, Zeiss, in collaboration with Intel, TSMC, imec, and others

First Deployment Target: Intel (expected ~2025–2026)

Main Use: Sub-2nm logic node patterning

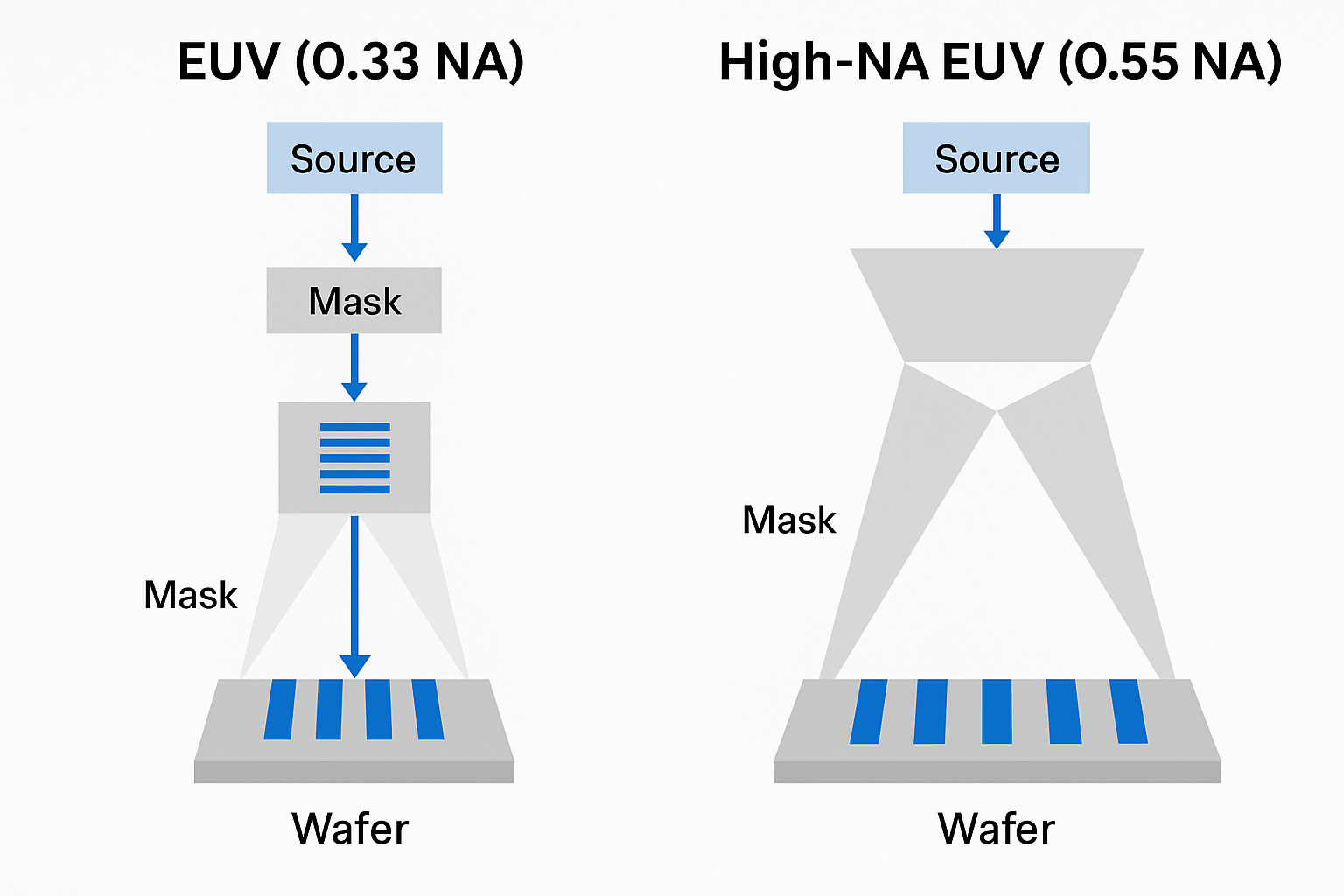

Predecessor: EUV (0.33 NA systems – ASML NXE series)

Tool Platform: ASML EXE series (e.g., EXE:5000, EXE:5200)

Key Collaborators: ASML, Zeiss, Intel, imec, TSMC, Samsung

Overview

High-NA EUV is the next major advancement in photolithography technology designed to extend the scalability of extreme ultraviolet (EUV) lithography into the sub-2nm process node era. “NA” stands for numerical aperture, a measure of the lens system’s resolution power.

While today’s production EUV systems use a 0.33 NA lens, High-NA EUV will increase that to 0.55 NA, dramatically improving the resolution and enabling single-exposure patterning at tighter pitches. It is considered a key enabler for advanced semiconductor nodes like Intel 14A, TSMC A14, and beyond.

What is Numerical Aperture (NA)?

Numerical Aperture (NA) in lithography is a measure of a system’s ability to focus light into fine patterns. Higher NA means:

-

Better resolution

-

Ability to print smaller features

-

Tighter pitches and higher density patterns

The Rayleigh resolution formula helps express this:

Minimum Feature Size=k1⋅λNA\text{Minimum Feature Size} = k_1 \cdot \frac{\lambda}{\text{NA}}

Where:

-

λ\lambda is the wavelength (13.5 nm for EUV)

-

NA is numerical aperture

-

k1k_1 is a process constant

By increasing NA from 0.33 to 0.55, High-NA EUV can pattern features ~70% smaller with the same process complexity.

Technical Features

1. Lens System

-

Developed by Carl Zeiss SMT, the High-NA EUV lens features a larger mirror angle and numerical aperture of 0.55.

-

Uses Schwarzschild optics (multi-mirror reflective system) adapted to handle higher magnification and tighter tolerances.

2. Higher Resolution

-

Targeted for 20nm pitch single-pattern capability (vs. ~30nm for 0.33 NA).

-

Reduces the need for multi-patterning, improving throughput and design rule simplification.

3. EUV Source and Power

-

Based on the same 13.5 nm wavelength from tin-based plasma sources (LPP).

-

Requires higher EUV power and improved optics to compensate for smaller field size.

4. Field Size Reduction

-

High-NA systems have a smaller slit and field size, necessitating changes in chip layout strategy.

-

Die stitching techniques may be used to create large dies from smaller fields.

5. Metrology and Mask Challenges

-

Masks need higher precision and defect control.

-

Pellicles (protective membranes) must be thinner and more transparent to EUV.

-

New resist materials and line-edge roughness (LER) controls are required.

Tool Platform: ASML EXE Series

| Tool | NA | First Shipments | Customers |

|---|---|---|---|

| NXE series | 0.33 | 2016–ongoing | All leading fabs |

| EXE:5000 | 0.55 | 2023 (Intel) | Intel, imec |

| EXE:5200 | 0.55 | 2025+ (HVM) | Intel, TSMC, Samsung (planned) |

-

The ASML EXE:5000 is a development tool delivered to Intel for early R&D.

-

The EXE:5200 is the production model, capable of high-volume manufacturing (HVM) by 2025–2026.

Use Cases and Node Targets

High-NA EUV is expected to be deployed for the following nodes and beyond:

| Company | Node | High-NA Use Target |

|---|---|---|

| Intel | 14A | First adopter (2025–2026) |

| TSMC | A14 or N1 | Research underway (2026+) |

| Samsung | SF2 / SF1.4 | Expected in roadmap (TBD) |

| imec | Various R&D nodes | Process pathfinding |

Initial use cases:

-

Logic transistor scaling (GAA, CFET)

-

Interconnect scaling with tighter metal pitches

-

Chiplet I/O optimization (via UCIe + denser bonding)

Benefits

| Benefit | Description |

|---|---|

| Higher Resolution | Enables smaller features and denser designs |

| Fewer Multi-Patterning Steps | Simplifies manufacturing complexity |

| Better Edge Placement Accuracy | Crucial for yield and scaling |

| Enabler for 1.5nm and Beyond | Extends Moore’s Law scalability |

| Improved Performance & Power | Enables transistor and interconnect optimizations |

Challenges

| Challenge | Explanation |

|---|---|

| Tool Cost | Over $300 million per tool, high capital expenditure |

| Field Size Reduction | Smaller exposure areas complicate layout planning |

| New Resists Needed | High-NA requires stiffer and more precise photoresists |

| Mask and Pellicle Engineering | Demands ultra-clean and precise optics |

| Throughput Concerns | Higher resolution = more exposure time, affects wafer-per-hour (WPH) |

Intel’s Leadership in High-NA EUV

-

Intel is the lead customer for High-NA EUV.

-

First EXE:5000 tool delivered to Oregon R&D fab in 2023.

-

Planning to use High-NA for Intel 14A and future process nodes.

-

Intel collaborates closely with ASML and imec to optimize High-NA patterning, resist materials, and tool operation.

Future Outlook

-

High-NA EUV is a critical enabler for sustaining Moore’s Law into the angstrom era.

-

Could be combined with other techniques like CFET, advanced packaging, and hybrid bonding to enable future logic scaling.

-

Research into even higher NA, EUV double patterning, and patterned mask techniques continues at imec and national labs.

Conclusion

High-NA EUV represents the most advanced lithography platform ever developed, pushing optical resolution beyond previous limits. While it brings engineering, cost, and integration challenges, its potential to enable sub-2nm logic nodes with better PPA (Performance, Power, Area) scaling is unmatched.

As fabs like Intel and TSMC race toward the angstrom era, High-NA EUV will play a foundational role in next-generation chip manufacturing and semiconductor innovation.

A Century of Miracles: From the FET’s Inception to the Horizons Ahead