Semiconductors have been central to the information revolution which is reshaping society. The modern world would not exist without this critical resource. Further, semiconductors are central to many sustainability solutions such as the enablement of smart infrastructure, electrification, and virtualization. One of the consequences of this tremendous growth is the ever increasing generation of e-waste. How big is this problem ? Is there a way to solve this problem ? Let’s examine the situation.

What is the nature of the e-waste problem ?

E-waste is the result of electronic products which have outlived their usefulness. Waste electronics contain several toxic additives or hazardous substances such as mercury, brominated flame retardants (BFR), chlorofluorocarbons (CFCs), or hydrochlorofluorocarbons (HCFCs). Without safe disposal, this waste stream poses significant risks to the environment and to human health. In fact, the toxic nature of E-waste has caused countries such as China to stop accepting e-waste shipments from the west, and prompted this Atlantic article to ponder “ Is This the End of Recycling?” Other locations for e-waste disposal have included third-world countries such as Ghana (Video Story) and Pakistan (Video Story). The e-waste problem is increasingly becoming visible in the popular consciousness. Recent articles include:

- The World Has an E-Waste Problem (Time)

- We dissected nearly 100 devices to study e-waste. What we found is alarming (fast company)

- News by Numbers: India’s mountain of e-waste (Forbes)

How did we get here ?

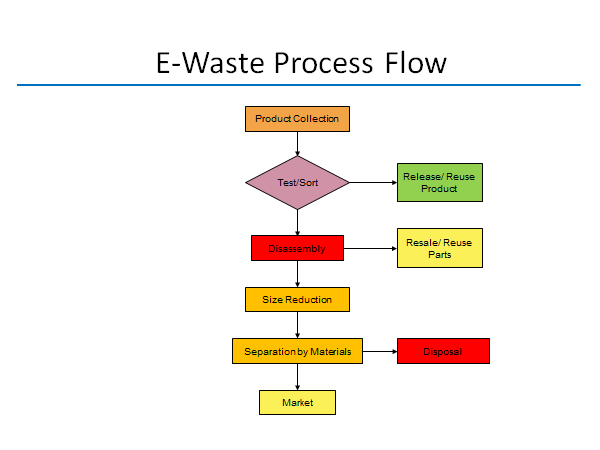

Of course, the starting point is the explosion of consumer devices which are reshaping society. Consumer devices are of particular concern because of the both high volume and short lifetime of use. After their end of useful life, electronic products turn into e-waste and follow a backwards deconstruction flow as shown in the figure below. The fundamentals of the flow are to use a managed process to salvage value when economically appropriate, and if value cannot be found, the product results in a landfill. The large steps are:

- Product Collection: A percentage of e-waste (only 35% in US) is collected in “official” e-waste where it goes through a reclamation process. The rest end-up in landfills.

- Disassembly: Products are disassembled into major components if the cost of disassembly is viable. Otherwise the product is shredded. As an example, Apple has built robots such as daisy which employs mass volume techniques to reduce the costs dramatically.

- Chip Reuse: Valuable chips can be extracted and reused based on the economics of doing so (extraction, secondary markets). Unfortunately, the secondary markets for these chips are dark, and prone to issues of counterfeiting. In some cases, these can even lead to national security issues.

- Materials Extraction: Finally, valuable elements such as gold/silver can be extracted in a chemical deconstruction process.

In the best of circumstances, these processes are done in safe working conditions, but as the video stories above show, these processes often occur in third-world countries under less than ideal conditions.

What is the pathway to a solution ?

The electronics industry has spent countless billions on research to build fantastic products at incredibly low costs. Today, for the most part, when a product moves into the e-waste bucket, it’s value moves from an incredibly engineered machine down to its base value in elemental materials. This is akin to viewing the human body for its mineral value.

A very critical issue is the ability to capture value at higher levels of reuse because that changes the economic dynamics of collection and disposal to a landfill. Today, the research investment in the backwards flow is remarkably lacking. Research and a minor amount of industry wide standards cooperation along a number of vectors can change the economics of e-waste significantly. These vectors include:

- Mechanical Disassembly: Mechanical disassembly is a key cost which must be managed. Robotics based high throughput, low cost mechanical disassembly is critical to addressing these costs. With a sufficiently efficient process, the economics of recycling become enabled. Research: Novel design-for-disassembly techniques which enable high volume, low cost disassembly while not compromising product performance are required. Standards/Industry Cooperation: Ideally, any robotics based disassembly techniques are provided in open standards which enable the e-waste eco-system.

- Board and Subsystem Reuse: If the whole product cannot be reused, research in productive ways to reuse natural subsystems is desirable. Research: Most dominant consumer devices contain more powerful capability than the Apollo space computers. This capability should have a value which is useful for other domains. Computer architecture research which finds valuable repurposing the major consumer platforms (laptops, mobile phones, tablets, etc) can significantly shift the economics of reuse. Standards/Industry Cooperation: To fruitfully use a board, the first step is to validate its correctness, so standards for testing the boards with associated test suites are invaluable. OEMs may even consider a “Certified Board” construct to enable this process.

- Chip Reuse: Safe and scaled manufacturing methods for board disassembly can lower the costs to obtain chips. Once the chip is available, the reuse flow is well understood, and this process occurs today. However, the chips themselves are in dark secondary markets. Standards/Industry Cooperation: To fruitfully use these chips, Semiconductor companies should consider a “Certified Chip” construct where they are actively engaged in the validation process.

- Materials Extraction and Disposal: Today, various chemical techniques are used to harvest key elements from e-waste. Research: Continued research on lowering the cost of extraction and extracting more value in a safe manner can lead to positive consequences. A recent example is the work of ex-Tesla employees with Redwood Materials to extract lithium from batteries. Standards/Industry Cooperation: Standards on the major processes for extraction and disposal of these materials is likely to lead to lowering of costs and higher levels of reuse.

Why now ?

Good citizenship and the potential for building profitable businesses are good reasons for the electronics industry to pursue solving the e-waste problem. This work can certainly be part of any ESG reporting for the investment community. However, an urgency to this process may well be to address the rise of the coming regulatory response. Significant activity to date includes:

- Europe: In the european Union, the fundamental concepts of circular material flows and “right to repair” are gaining traction.

- US States: In the US, over 25 states have enacted electronics waste laws.

Recently, some industry wide movement has happened recently with the World Economic Forum’s announcement of the Circular Electronics Partnership (CEP), and there has been some investment from the US Government in e-waste research with entities such as the Re-Made institute ($70M). However, to make progress, it is very likely that the traditional standards bodies such as CTA and SIA will have to get involved. In addition, the traditional funders of the forward flow research such as Semiconductor Research Consortium (SRC), NSF, and perhaps even DoD will need to participate. Overall, Industry focus on standardization, market formation, and reuse research, can significantly impact e-waste.

Note 1: There has been some churn on the e-waste issue direction in the popular media. The article “Is E-Waste Declining ? The rest of the story “ addresses this topic.

Note 2: The Global E-waste Monitor 2020 report by Vanessa Forti, Cornelis Peter Baldé, Ruediger Kuehr, and Garam Bel from the United Nations University provides a decent background to this topic.

Share this post via:

A Century of Miracles: From the FET’s Inception to the Horizons Ahead