Together with our R&D partner CEA-Leti, we recently completed an environmental initiative in which we analyzed the environmental impact of Weebit’s Resistive Random-Access Memory (ReRAM / RRAM) technology compared to Magnetoresistive Random Access Memory (MRAM) – another emerging non-volatile memory (NVM) technology. The results were extremely positive for Weebit’s Oxide-based ReRAM (OxRAM), which was jointly developed with Leti, showing the environmental impact of ReRAM is much lower than that of MRAM.

A bit of background

The overall contribution of the semiconductor industry to global greenhouse gas (GHG) emissions is increasing as demand for semiconductors continues to grow. To mitigate negative impacts, environmental programs are extremely important for all players in the semiconductor ecosystem. In addition to CO2 emissions, semiconductor manufacturing can use a significant amount of energy, water, rare natural resources, and chemicals, which can contribute to global warming. The choices semiconductor companies make in design and specification phases, including their memory technology choices, are key to reducing a company’s overall carbon footprint.

MRAM is effectively the only other kind of emerging NVM that is commercially available today at foundries. It stores data as resistance using magnetic fields (versus ReRAM which stores it as resistance of a solid dielectric material, and flash which stores data as electric charges). MRAM has high endurance and is more often used as a replacement for embedded SRAM than for embedded flash. Still, there are companies using MRAM today as a replacement for embedded flash that do so because until now there hasn’t been a production-ready alternative at smaller geometries.

Compared to MRAM, Weebit ReRAM is the logical choice for embedded applications, with the number one reason being ease of manufacturing. Weebit ReRAM requires significantly fewer layers and masks and doesn’t use exotic materials or special equipment, so it can be manufactured in the standard CMOS production line and doesn’t require designated cleanroom facilities. All this translates to lower costs. MRAM adds an estimated 30-40% to wafer cost, compared to ReRAM’s 5-7%. We will go into more depth on MRAM in a future article, but for now, suffice it to say that ReRAM has a long list of advantages over MRAM, and in our new study, we’ve outlined yet another advantage – ReRAM is much more ecologically friendly!

What we looked at

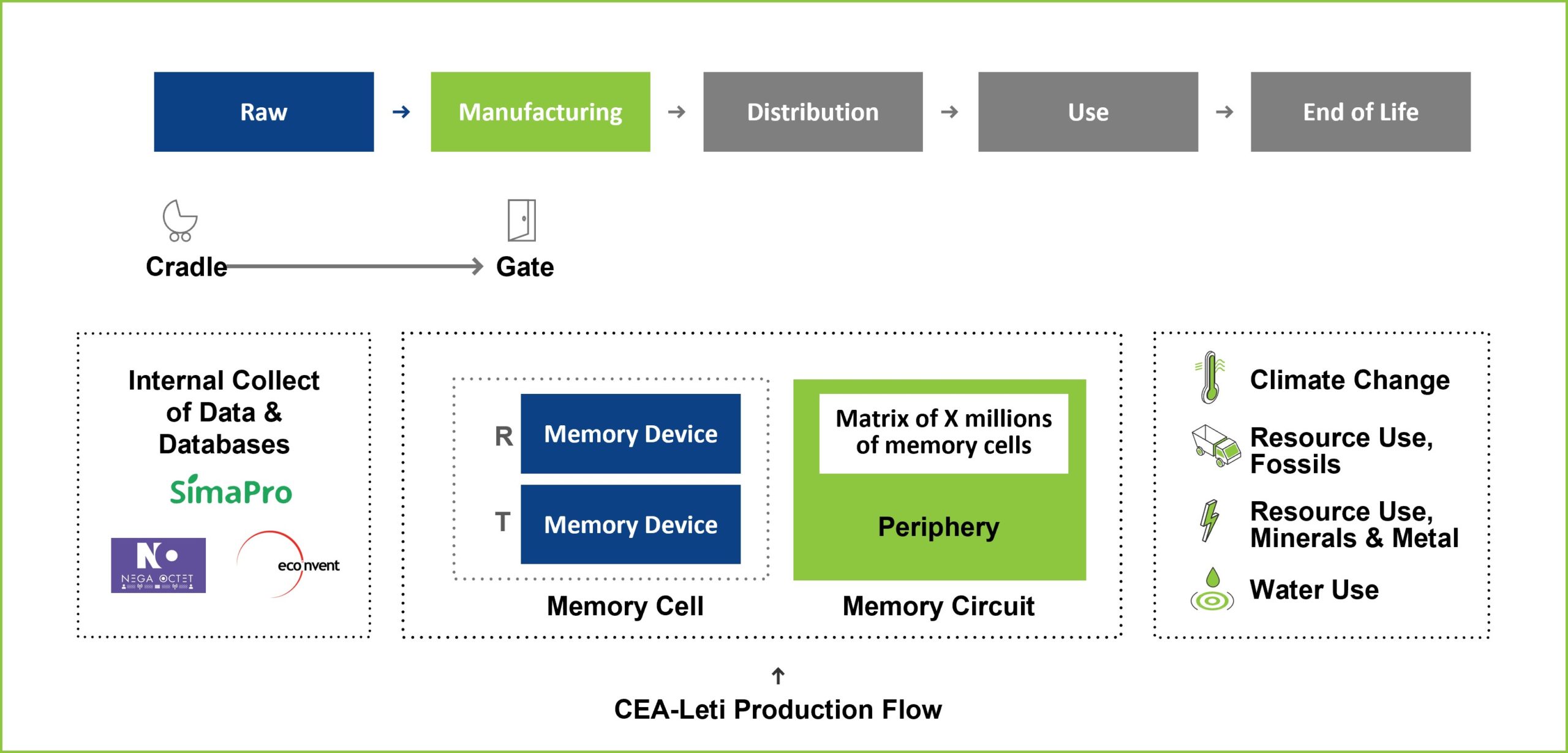

The team at CEA-Leti estimated the contribution of both OxRAM and MRAM to climate change, focusing on the production flows of each technology. To enable a fair comparison, the study looked at each technology in an identical die area in a similar process node and considered only the memory cell portion. They looked at raw materials and manufacturing processes (cradle to gate) without including infrastructure and abatement. Scroll to the end of the article to learn more about the data collection for the study*.

Key results

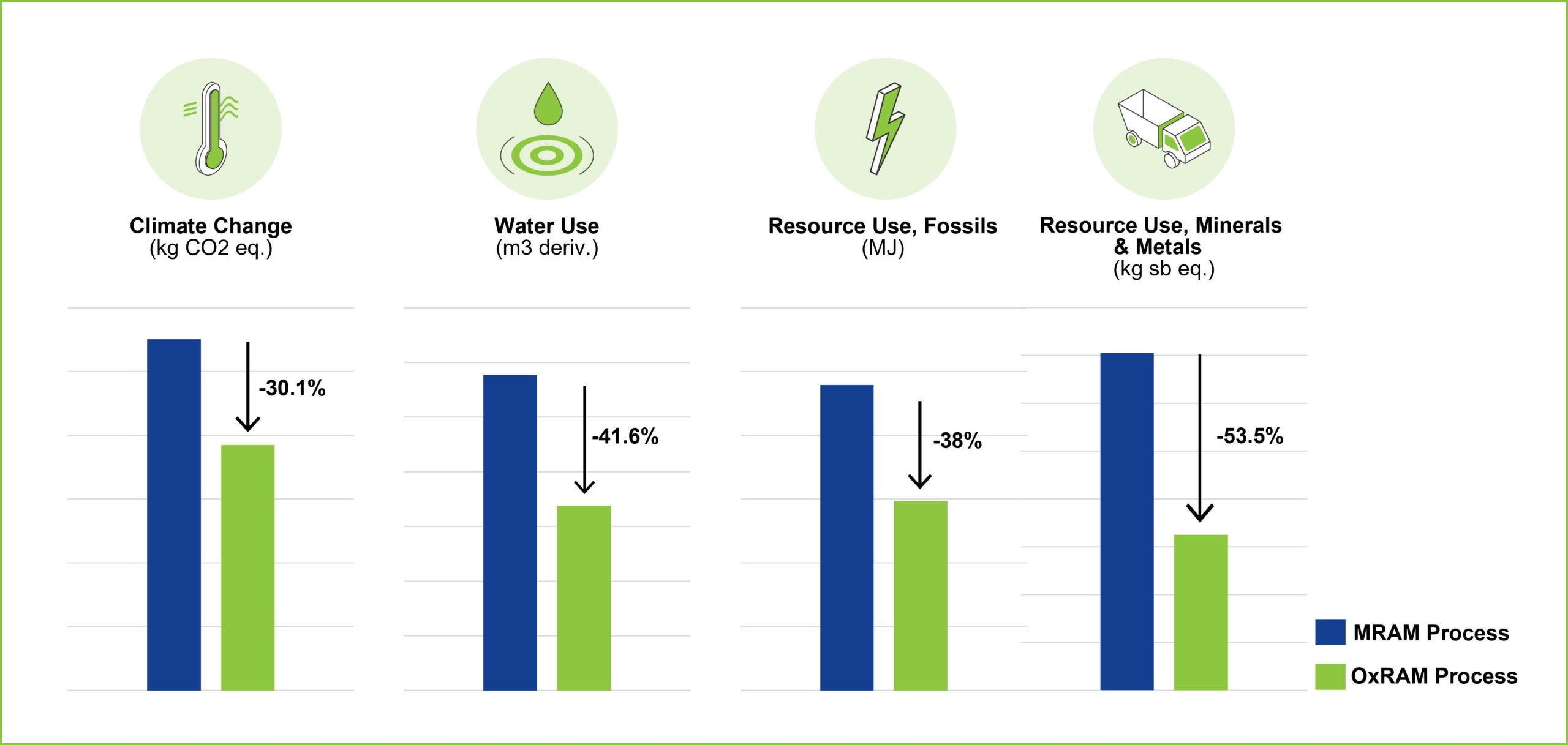

The study found that on all measured parameters, OxRAM demonstrated a better GHG related profile than MRAM. Below we’ve listed some of the key results.

ReRAM demonstrated the following benefits over MRAM:

- 30% reduction in GHG emissions

- 41% reduction in water use

- 53% reduction in use of minerals and metals

- 36% less electricity to process

The importance of critical materials

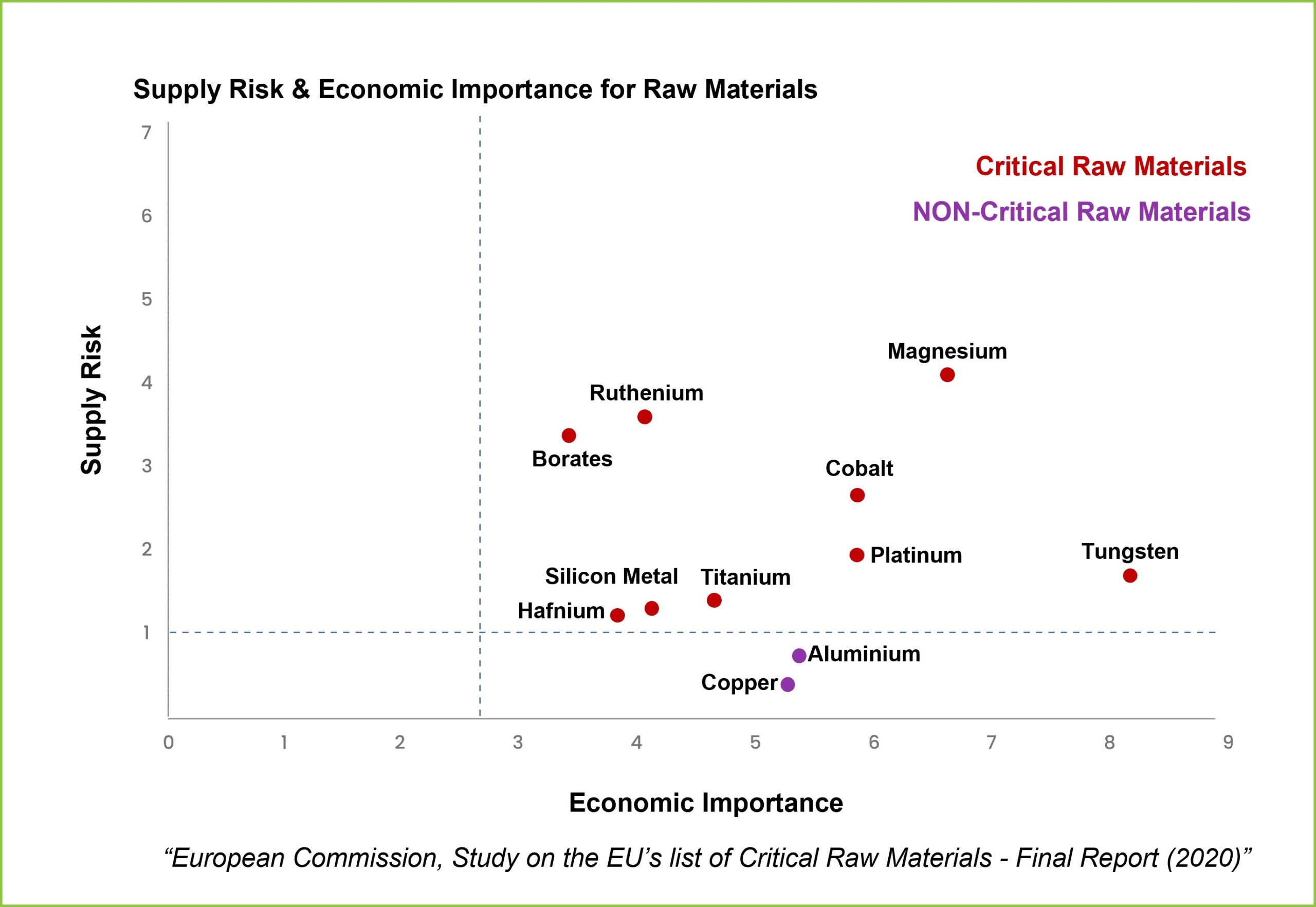

One of the key study findings is that the MRAM flow contains 2X more critical raw materials than the OxRAM flow. As defined by the European Union, the two main factors that define the criticality of a material are supply risk and economic importance. Supply risk is determined by criteria including supply concentration, import reliance, governance performance of suppliers, trade restrictions and criticality of substitute materials. Economic importance is based on a material’s added value, importance in end use applications, and the performance of any substitute materials. In the below chart you can see the criticality of various materials used in semiconductor manufacturing.

Many of the materials required for MRAM are at high supply risk, and some – like magnesium, platinum and cobalt – are critical in terms of both supply risk and economic importance. Any disruption of access to such materials, whether from political challenges, extreme weather, COVID lock-downs, or other issues can put a project at risk. In addition, the borates that are used in MRAM manufacturing have a very poor recycling input rate (less than 1%) – yet another consideration when looking at environmental impacts.

The bigger picture

There are many environmental considerations that come into play for semiconductor technologies such as NVMs. In our study, we specifically looked at the memory cells and circuits themselves, without accounting for the rest of the chip (e.g., microcontrollers) or the environmental impacts of the product lifecycle, such as power consumption during its usage and end-of-life recycling.

The results we’ve shown here can provide customers with confidence that when they are choosing an alternative to flash for their next design, they can not only count on the many known advantages of ReRAM, but they now know that Weebit ReRAM has a lower environmental impact and less supply chain risk than MRAM.

* Notes about the study

- Primary data: All data about the steps of the production flow came from internal collection by Leti, which has broad expertise in both MRAM and ReRAM. Quantity and types of materials used (metals, chemicals and gases), water consumption, energy consumption, and air/water emissions were measured by Leti.

- Secondary data: All raw materials data came from the Eco Invent database.

- Production is in France and therefore the energy mix is the French mix.

Also Read:

How an Embedded Non-Volatile Memory Can Be a Differentiator

CEO Interview: Coby Hanoch of Weebit Nano

Share this post via:

Comments

One Reply to “Weebit ReRAM: NVM that’s better for the planet”

You must register or log in to view/post comments.