Samsung Foundry held the 'SAFE Forum 2025' for its partners at the Samsung Finance Campus in Seocho-gu, Seoul on the 1st. The 'Samsung Foundry Forum (SFF)' was not held and was replaced with a VIP dinner.

Samsung Electronics' foundry division has officially announced the postponement of mass production of 1.4 nanometer (nm) semiconductors. It has set a target for mass production in 2029, which is two years later than previously. This can be interpreted as an attempt to improve profitability by increasing the perfection of the 2㎚ or higher process and increasing the operating rate instead of delaying the mass production of 1.4㎚. Samsung Electronics shared this strategy at the ' SA

FE Forum 2025' held for its partners at the Samsung Finance Campus in Seocho-gu, Seoul on the 1st . It was understood that during the announcement made by Shin Jong-shin, Vice President and Head of Design Platform Development at the Foundry Division, the date of introduction of the 1.4㎚ process was specified as 2029. Samsung Electronics had previously announced in 2022 that it would mass produce 1.4㎚ semiconductors starting in 2027, but this has been adjusted. This is one year later than 2028, which its rival TSMC announced as its target date for mass production of 1.4㎚.

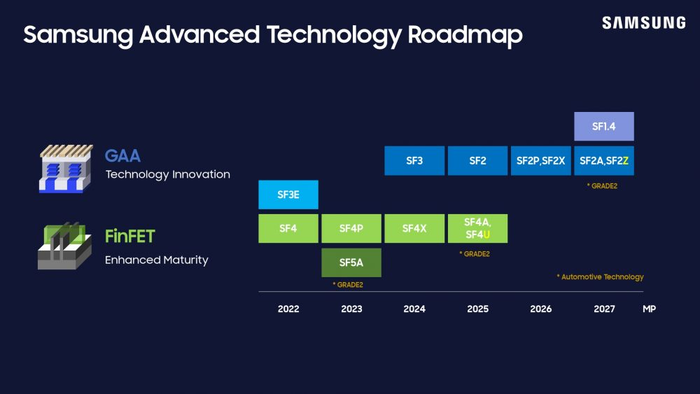

This is interpreted as a solution to the current situation where it is recording a deficit due to a decrease in the operating rate. It is estimated that Samsung Foundry posted a deficit of 4 trillion won last year alone due to a decrease in the operating rate after major customers withdrew from the advanced process. Accordingly, the 2㎚ (SF2) process will proceed with mass production this year as originally planned, but the technology roadmap has been revised thereafter. It plans to focus on stabilizing the 2㎚ process such as SF2P (2nd generation) and SF2X (3rd generation) until 2028. It also plans to focus on securing profitability by increasing the operating rate of the 4, 5, and 8㎚ processes, whose technology has been relatively stabilized.

To this end, it is reported that it has asked its partners to develop design assets (IP) to improve the process perfection and to attract customers. Telechips and Rebellion, which use the process, also announced cases of collaboration with Samsung Foundry on this day. Meanwhile, Samsung Foundry has been competing with TSMC for the title of 'world's first' in the advanced process. It also achieved mass production of the 10㎚ process in 2016 and the 3㎚ process in 2022 ahead of TSMC. However, it has been evaluated that it falls behind in terms of process perfection.

Technology roadmap announced at 'Samsung Foundry Forum (SFF) 2024' last year

삼성 파운드리, 1.4㎚ 2029년 양산…'가동률 회복' 집중

삼성전자 파운드리사업부가 1.4나노미터(㎚) 반도체 양산 순연을 공식화했다. 기존 대비 2년 늦은 2029년 양산을 목표로 내세웠다. 1.4㎚ 양산을 늦추는 대신 2㎚ 이상 공정 완성도를 높이고 가동률을 끌어올려 수익성을 개선하려는 시도로 풀이된다. 삼성전자는 1일 서