Everyone knows design complexity is exploding. What used to be difficult is now bordering on impossible. While design and verification challenges occupy a lot of the conversation, the problem is much bigger than this. The new design and manufacturing challenges of 3D innovations and the need to coordinate a much more complex global supply chain are examples of the breadth of what lies ahead. The opportunity of ubiquitous use of AI creates even more challenges. I’m not referring to designing AI chips and systems, but rather how to use AI to increase the chances of design success for those systems.

Data is the new oil, and the foundation of AI. That statement is quite relevant here. What is needed to tame these challenges is a way to collect data upstream in that complex global supply chain and find ways to extract insights that will be used to drive decisions and actions further down the supply chain. Doing that across a complex supply chain requires a highly scalable and secure platform. It turns out PDF Solutions has been quietly building what’s needed to make all this happen. Let’s examine what they’ve been doing and what comes next as PDF Solutions adds security and scalability to manufacturing and test solutions.

Building the Foundation

There are two key products from PDF Solutions that build an infrastructure for the future. A bit of background will set the stage.

First is the Exensio® Analytics Platform, which automatically collects, analyzes and detects statistical changes in manufacturing test, assembly, and packaging operations that negatively affect product yield, quality, or reliability, wherever those operations occur.

The suite of modules in this product enables fabless companies, IDMs, foundries, and OSATs to securely collect and manage test data, assure high outgoing quality, deploy machine learning to the edge, establish controls around the test process, and improve efficiency across the manufacturing supply chain.

The machine learning capabilities will be key to what comes next. More on that in a moment. The product has quite a large footprint across manufacturing and test operations worldwide.

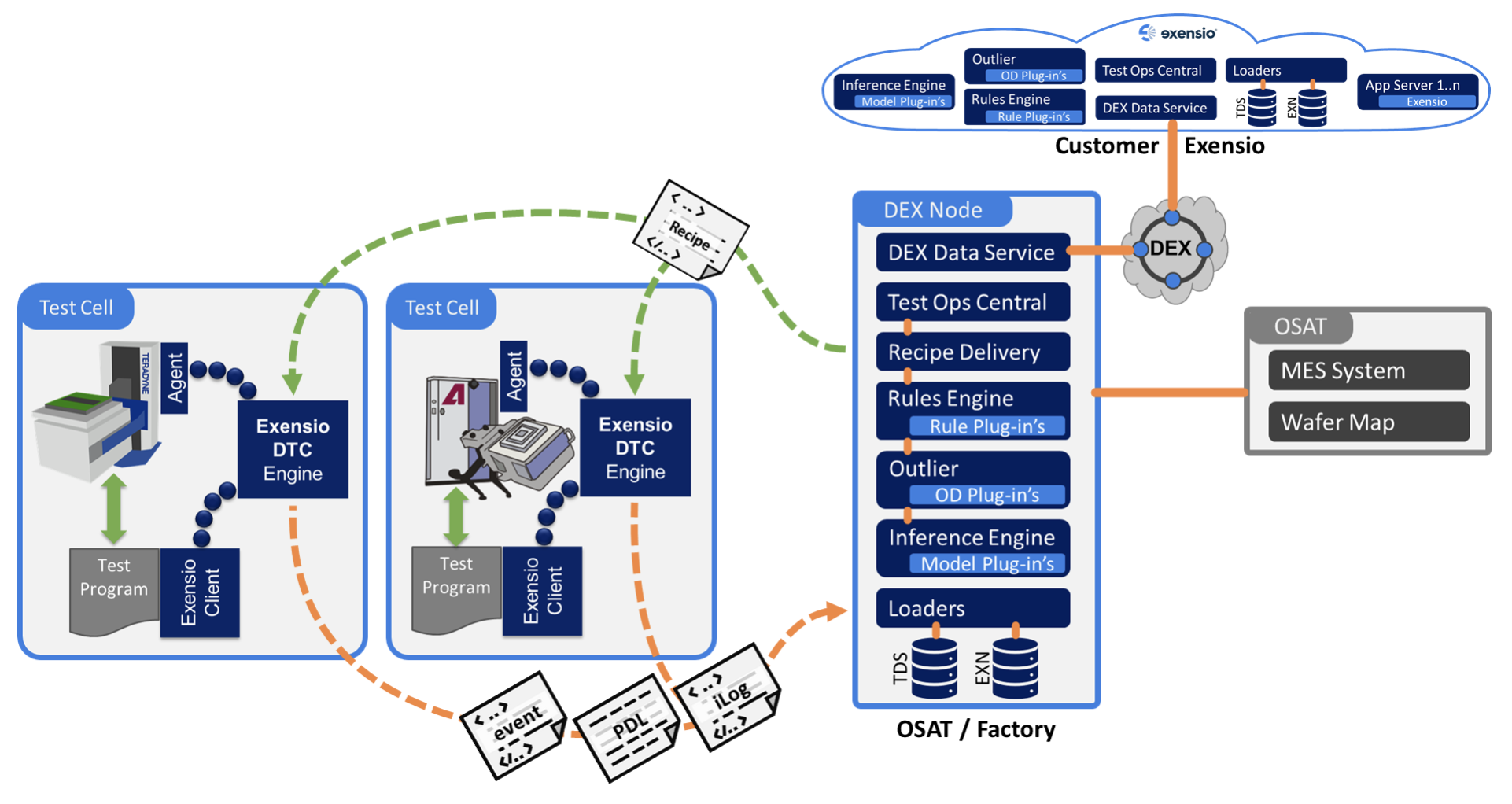

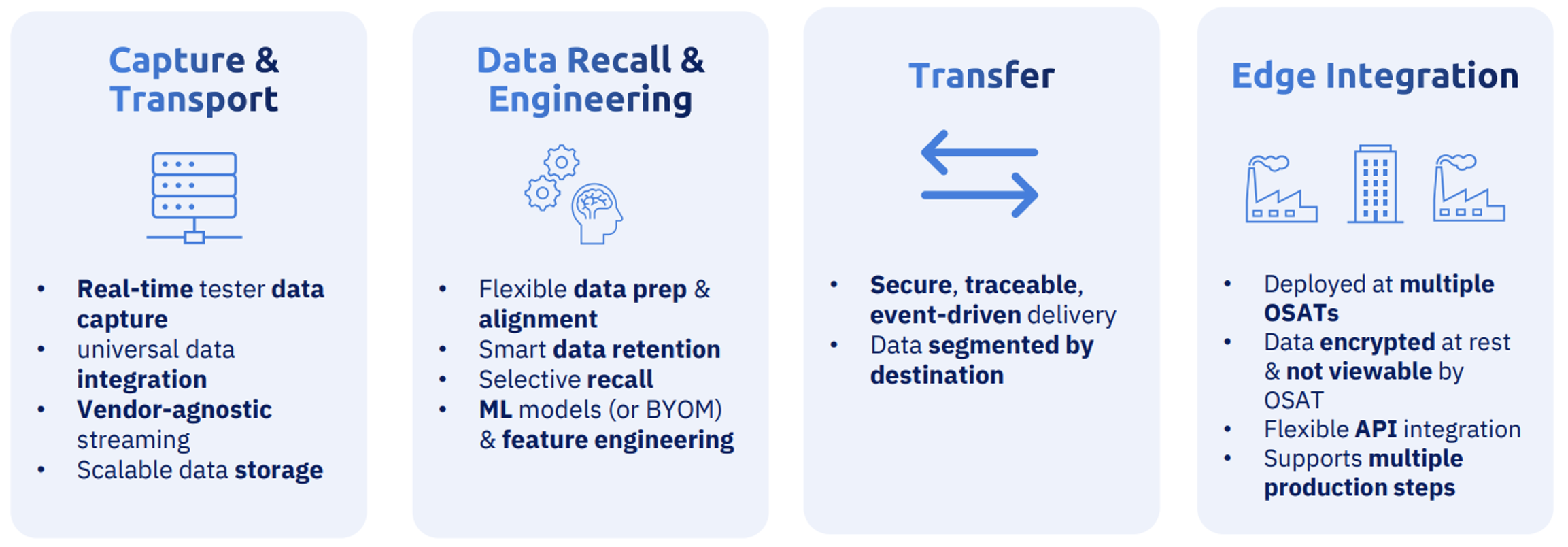

Of course, a massive data analytics platform like this needs many sources of data across the worldwide supply chain to power it. To enable this part of the platform there is DEX, PDF’s data exchange network. DEX is an infrastructure deployed globally at OSAT locations that connects to potentially every test cell or test and assembly equipment across the worldwide supply chain. It automatically delivers test rules, models & recipes, and brings, in real time, all of that test data back to Exensio. There, it will be normalized using PDF Solutions semantic model that ensures it is always complete, consistent and ready for analysis. DEX is the plumbing for test rules, models and data for Exensio if you will.

I began my career in test data analytics. Back then, the number and type of testers that were part of that process was extremely small compared to what exists today. In spite of that, I can tell you that interfacing to each source of test data, acquiring the data and ensuring it was accurate and timely was a huge challenge. The problem has gotten much, much bigger. DEX is a combination of hardware and software developed by PDF Solutions that interfaces to all data sources, validates the information and transports it to the required location for timely analysis. This is a very complex process.

The system is optimized to handle the unique challenges of semiconductor data acquisition, enabling PDF Solutions to manage petabytes of information on cloud. The diagram below illustrates how DEX feeds critical data to Exensio.

What’s Next

Systems the size and scope of Exensio and DEX have already created a substantial impact on the semiconductor industry. The graphic at the top of this post illustrates some of the areas that have benefited from these systems. The next chapter of this story will focus on a concept called Data Feed Forward or DFF. PDF sees DFF providing an enterprise solution to collect, transform and distribute data across a customer’s supply chain to enable advanced test methodologies utilizing feed-forward data.

Using PDF’s global infrastructure, test data can be captured upstream and transported to the edge to be used to inform optimized strategies for downstream testing. The concept of feed forward data enablement isn’t new. It has been used successfully to optimize physical implementation by using early data to inform estimates for late-stage implementation. In the case of manufacturing and test, a globally available, secure and scalable data infrastructure can be used to optimize test in the chiplet and advanced packaging era.

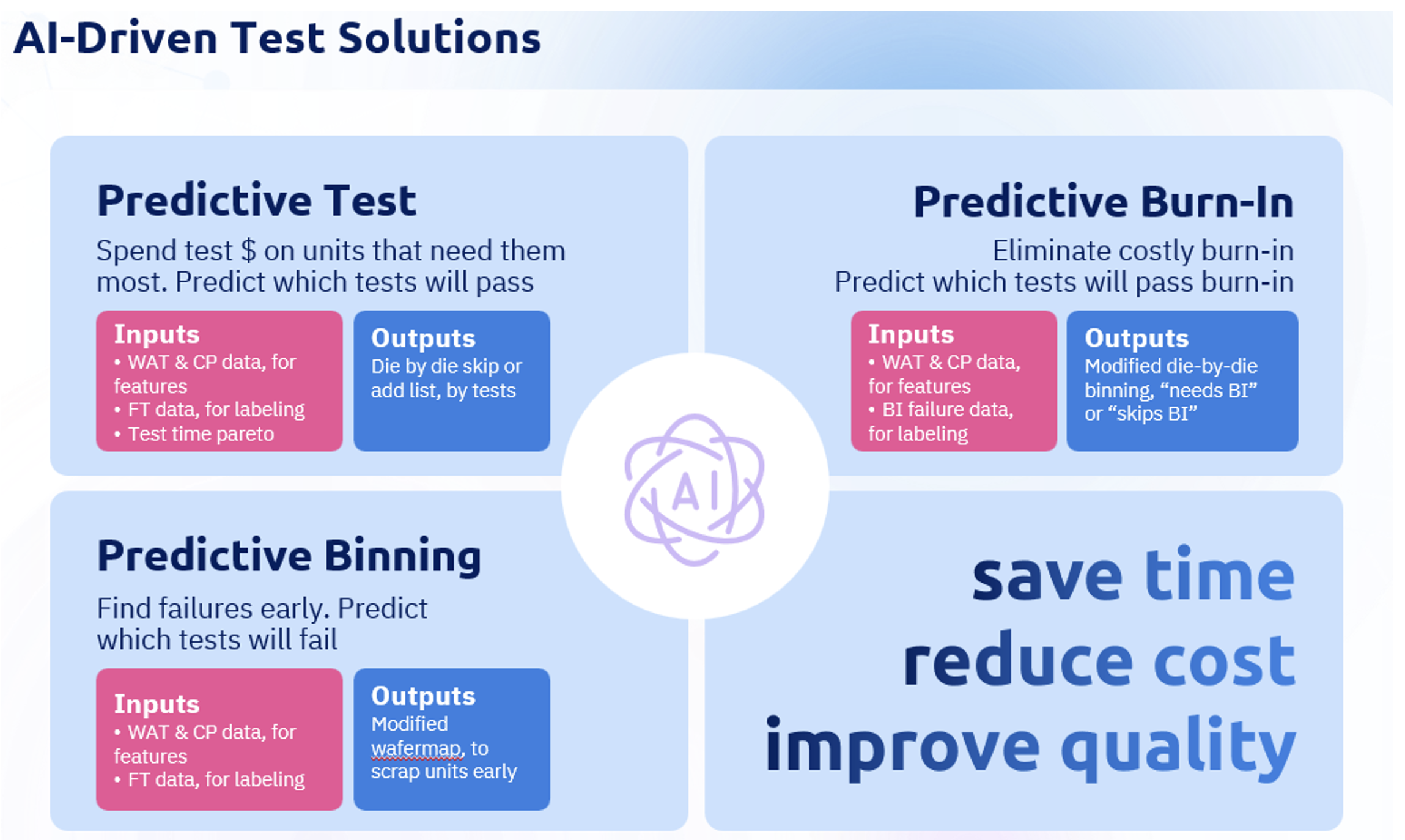

We are seeing the dawn of AI-driven test from PDF Solutions based on this technology. The goal of AI-driven test is to save time, reduce cost and improve quality. The diagram below summarizes the current three focus areas for this capability.

Digging Deeper

I had the opportunity recently to speak with Ming Zhang, vice president of Fabless Solutions at PDF. I’ve worked with Ming in the past and I’ve always found him to be insightful with a strong view of the big picture and what it all means. So, getting his explanation of AI for test was particularly valuable. Here’s what I learned about the three AI-driven test solutions summarized above.

Ming explained that Predictive Test has an optimization focus. As we all know, test insertions are expensive in terms of manufacturing time and tester cost. Most test strategies apply the same test program to all chips. But what if that could be optimized? Using feed forward data, the parts of a design that are both robust and potentially weak can be identified. Using this kind of unit-specific data, a test program can be developed that is optimized for the specific part. Ming explained what that meant is that test for parts of the design that were demonstrated as robust could be minimized or even skipped.

On the other hand, parts of the design that showed potential weakness could be tested more rigorously. In the end, the actual test time might be the same as before, but the tests applied would be more effective at finding good and bad die, so quality would improve for the same, or lower test cost.

We then discussed Predictive Binning. Ming described this approach as a straight cost saving measure. He explained that based on early data, chips that were likely to fail a test step could be removed or binned out. This essentially avoids test costs that would result in a failure so test cost would be reduced.

We then discussed Predictive Burn-in. This is another cost saving measure. In this case, the devices that have exhibited robust behavior can be identified as not requiring burn-in. Since this process requires hundreds to thousands of hours using expensive measurement and ambient control equipment, a significant cost saving can be realized by avoiding burn-in where it’s not necessary.

Ming pointed out that all of these technologies apply advanced AI algorithms to the massive worldwide manufacturing database managed by PDF Solutions. The initial AI models are developed by PDF. Ming went on to explain that some of its customers want to build proprietary models to drive test decisions as well. PDF support this process also, creating an environment where certain customers can build their own AI for test models and algorithms to enhance competitiveness.

I was quite energized after my discussion. Ming painted a rather upbeat and exciting view of what’s ahead. By the way, if you happen to be in Taiwan on September 12, Ming will be presenting this work at the SEMICON event there.

The Last Word

PDF Solutions’ president, CEO and co-founder Dr. John Kibarian made a comment recently that steps back a bit and takes a bigger picture view of where this can all go. He said:

“Collaboration from the system company, all the way back to the equipment vendor, is important today in order to get out new products. Then once those products are launched, the collaboration for the ongoing maintenance of that production flow is requiring a lot more effort. The collaboration required is going to go up. It will be doable at scale only because the industry is going to require it to be doable.”

The vision painted by John is quite exciting as PDF Solutions adds security and scalability to manufacturing and test.

Also Read:

PDF Solutions and the Value of Fearless Creativity

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.