Teenes

New member

Experience the revolution where SWIR (Short-Wave Infrared) and NIR (Near-Infrared Radiation) camera innovations on VR20i G2 redefine reel-to-reel inspection for WLCSP specifications.

According to Verified Market Research, the Global Wafer-Level Packaging Market is anticipated to record a CAGR of 6.10% from 2024 to 2030 and reach $25.7 billion at the end of the forecast period, which is 2030.

However, WLCSP's advanced manufacturing flow poses significant challenges. The singulation process from wafer to die can potentially affect both inner and surface performance. Additionally, fastening WLCSP to protective packaging before cutting complicates the inspection of micro defects using traditional methods.

To address these challenges, ViTrox proudly presents the VR20i G2 Post Seal Vision Handler solution. This advanced vision inspection technology, with its customisable features, integrates a specialised SWIR solution and the high resolution of the NIR camera. The VR20i G2 ensures precise defect detection in in-tape components, making it the ultimate solution for efficient post-seal inspection. It greatly assists WLCSP manufacturers in overcoming the obstacles in their advanced manufacturing processes.

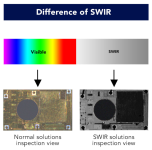

Here is the difference between the inspection views using the SWIR inspection solution and standard inspection solutions in ViTrox Post Seal Vision Handler - VR20i G2.

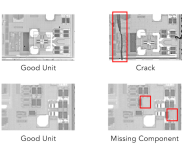

For the WLCSP package, inspecting the IC requires special light sources and lenses with penetration properties. VR20i G2 utilises SWIR technology paired with a military-grade SWIR camera, which can accurately detect internal defects by producing processed images that distinguish components of similar colour, thereby enhancing inspection efficiency. VR20i G2, equipped with the SWIR vision solution, can inspect inner die crack defects down to 25 μm. The inspection criteria include inner cracks, missing components, delamination, chip-off, and more. Thus, SWIR technology minimises escape rates and significantly enhances product quality.

In addition to our groundbreaking integration for WLCSP inspection, the VR20i G2 brings a series of exciting benefits:

Wafer Level Chip Scale Package (WLCSP)

Wafer Level Chip Scale Package (WLCSP) is a package integration of integrated circuits at the wafer level. With this specification, it is able to minimise die-to-PCB inductance, reduce size, and enhance thermal conduction, leading to cost savings and improved device performance. Consequently, WLCSP has garnered significant traction in industries necessitating unwavering reliability which usually are Automotive, Consumer, Industrial, Aerospace and Defense, etc.According to Verified Market Research, the Global Wafer-Level Packaging Market is anticipated to record a CAGR of 6.10% from 2024 to 2030 and reach $25.7 billion at the end of the forecast period, which is 2030.

However, WLCSP's advanced manufacturing flow poses significant challenges. The singulation process from wafer to die can potentially affect both inner and surface performance. Additionally, fastening WLCSP to protective packaging before cutting complicates the inspection of micro defects using traditional methods.

To address these challenges, ViTrox proudly presents the VR20i G2 Post Seal Vision Handler solution. This advanced vision inspection technology, with its customisable features, integrates a specialised SWIR solution and the high resolution of the NIR camera. The VR20i G2 ensures precise defect detection in in-tape components, making it the ultimate solution for efficient post-seal inspection. It greatly assists WLCSP manufacturers in overcoming the obstacles in their advanced manufacturing processes.

Short-Wave Infrared (SWIR)

Here is the difference between the inspection views using the SWIR inspection solution and standard inspection solutions in ViTrox Post Seal Vision Handler - VR20i G2.

For the WLCSP package, inspecting the IC requires special light sources and lenses with penetration properties. VR20i G2 utilises SWIR technology paired with a military-grade SWIR camera, which can accurately detect internal defects by producing processed images that distinguish components of similar colour, thereby enhancing inspection efficiency. VR20i G2, equipped with the SWIR vision solution, can inspect inner die crack defects down to 25 μm. The inspection criteria include inner cracks, missing components, delamination, chip-off, and more. Thus, SWIR technology minimises escape rates and significantly enhances product quality.

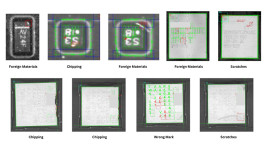

Near-Infrared Radiation (NIR)

ViTrox's VR20i G2 innovative solution integrates with a state-of-the-art 25MP NIR camera Resolution, specifically engineered to enhance differentiation between similar substances under visible light, thereby unveiling hidden details or compositions. With this feature, the surface defects can be identified obviously by capturing the infrared response, which separates the background and the components requiring inspection by reducing the effects of reflection and scattering of light. The NIR camera in VR20i G2 can pinpoint surface defects as minuscule as 30μm. The inspection criteria include chipping, scratches, foreign materials, and more.In addition to our groundbreaking integration for WLCSP inspection, the VR20i G2 brings a series of exciting benefits:

- Improved Productivity: Dual-track handle design delivers a surge in production efficiency

- Unmatched Flexibility: Supports various package types with advanced multiple vision inspection capabilities

- Hassle-Free Operations: Features an automated mechanism for track and dummy reel width adjustments and effortless tape insertion into the dummy reel

- Revolutionary Mark Inspection: Integrated AI Optical Character Recognition (OCR) ensures unparalleled accuracy and efficiency in mark inspection.