Patrick Gelsinger

And as you think about the turnaround story for Intel, I'd really like to say that we've now begun phase two. You know, in phase one of the transformation was this rebuilding of the company and being able to get back to process and product leadership and laying out our IDM 2.0 strategy. And I think about that as the most significant rebuilding of the company since the memory to microprocessor, transition.

And this idea that we had to get back to process leadership. We described that as our five nodes and four-year journey. And we see the finish line in the site. And since we released the fifth of those, right, the PDK for Intel 18A, we've seen a market uptick in activities in the industry. We now have about a dozen customers that are actively engaged with us around that PDK.

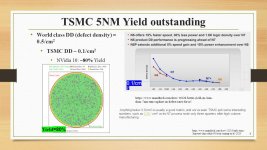

We have eight product tape-ins that we expect to finish by the middle of next year. And of course, Panther Lake and Clearwater Forest, our first client and server product. And I'm happy to update the audience that we're now -- for this as a production process, we're now below 0.4d0 as defect density. As we touched on last night, Ross, this is now a healthy process that we're looking forward, and we'll start production wafers with Panther Lake before the end of the year. So, we're on track to deliver that.

We're seeing an uptick in activity from the industry since the PDK 1.0 went out. And as we've also talked about in our advanced -- in our foundry strategy, our advanced packaging remains a huge differentiator. And since the beginning of the year, we have about a tripling of our deal pipeline in advanced packaging. So that continues to be the on-ramp for many of our foundry customers.

And as you think about the turnaround story for Intel, I'd really like to say that we've now begun phase two. You know, in phase one of the transformation was this rebuilding of the company and being able to get back to process and product leadership and laying out our IDM 2.0 strategy. And I think about that as the most significant rebuilding of the company since the memory to microprocessor, transition.

And this idea that we had to get back to process leadership. We described that as our five nodes and four-year journey. And we see the finish line in the site. And since we released the fifth of those, right, the PDK for Intel 18A, we've seen a market uptick in activities in the industry. We now have about a dozen customers that are actively engaged with us around that PDK.

We have eight product tape-ins that we expect to finish by the middle of next year. And of course, Panther Lake and Clearwater Forest, our first client and server product. And I'm happy to update the audience that we're now -- for this as a production process, we're now below 0.4d0 as defect density. As we touched on last night, Ross, this is now a healthy process that we're looking forward, and we'll start production wafers with Panther Lake before the end of the year. So, we're on track to deliver that.

We're seeing an uptick in activity from the industry since the PDK 1.0 went out. And as we've also talked about in our advanced -- in our foundry strategy, our advanced packaging remains a huge differentiator. And since the beginning of the year, we have about a tripling of our deal pipeline in advanced packaging. So that continues to be the on-ramp for many of our foundry customers.