Foreign media reported that Apple has contracted more than half of TSMC's 2nm production capacity by 2026. Reuters

Foreign media reported that Apple has booked more than half of TSMC's 2nm production capacity in 2026. The industry speculates that Apple's early booking of the most advanced production capacity with the wafer fab in the Apple silicon plan will prevent competitors from using the most advanced process technology, becoming one of its winning strategies and continuing to be the largest user of TSMC's most advanced production capacity.

TSMC will begin mass production of 2nm in the second half of 2025, with further expansion expected next year. MacRumors reports that Apple has secured at least half of TSMC's 2nm process capacity through 2026.

Apple contracts TSMC's 2nm production capacity

TSMC's largest customer remains Apple. According to TSMC's annual report, this largest customer will contribute a record NT$624.3 billion in revenue in 2024, a 14.2% year-over-year increase and accounting for 22% of total revenue. Analysts estimate that Apple is TSMC's largest customer. TSMC is fundamental to Apple's success in developing its own chips, as its advanced process technology enables higher performance for Apple chips.

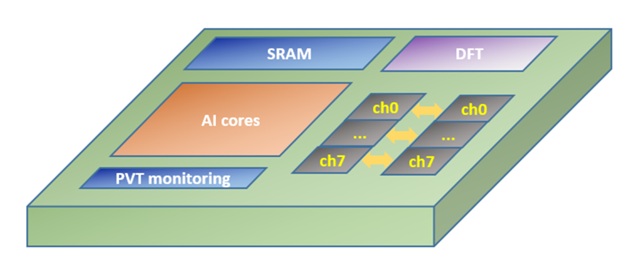

In addition to contracting the foundry capacity, industry sources have reported that Apple may use TSMC's latest packaging technology, Wafer-Level Multi-Chip Module (WMCM), for several of its product chips. This technology is expected to be used in the MacBook Pro's M6 chip, the Vision Pro helmet updated in 2026, and entry-level new iPhone models.

For nearly a decade, Apple has been one of TSMC's first and largest customers for its most advanced process technology. Tim Millet, Apple's Vice President of Platform Architecture, has previously shared the secret to Apple Silicon's success: the key lies in competitors being unable to directly access the latest technologies, such as the second-generation 3nm process. Apple has benefited greatly from this, benefiting both its products and its customers.

TSMC's current 2nm production bases are planned for the Baoshan and Kaohsiung plants in Hsinchu Science Park. Industry sources have reported that Apple has already fully booked TSMC's first batch of 2nm production capacity at Baoshan, while Kaohsiung's 2nm production capacity is planned to support non-Apple customer groups. This means that the Baoshan plant's capacity will support Apple's flagship applications, while the first batch of non-Apple application production capacity will be produced at the Kaohsiung plant. Intel is also striving to put 2nm into production this year.

TSMC's future capacity expansion plan is to expand the Baoshan plant in Hsinchu Science Park to four phases, and the Kaohsiung plant area to more than five phases. It is rumored that the Southern Taiwan Science Park plant can also dynamically upgrade production lines to introduce 2nm and even A16 processes to meet the strong demand from the customer base.

TSMC previously pointed out at a legal briefing that 2nm will enter mass production as scheduled in the second half of 2025. The number of product design finalizations in the first two years will be higher than that of 3nm and 5nm in the same period. Its mass production curve is similar to that of 3nm. It will also launch N2P process technology as an extension of the 2nm family for application in smartphones and HPC, and mass production is expected in the second half of 2026.

台積2奈米傳蘋果包過半產能 將讓對手用不到最先進技術 | 產業熱點 | 產業 | 經濟日報

外電報導,傳出蘋果包下台積電2026年2奈米過半產能,業界推測,蘋果在蘋果矽(Apple silicon)計畫提早和晶圓...