fansink

Well-known member

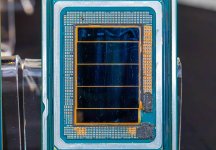

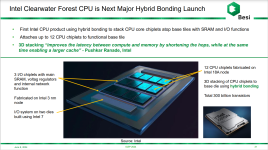

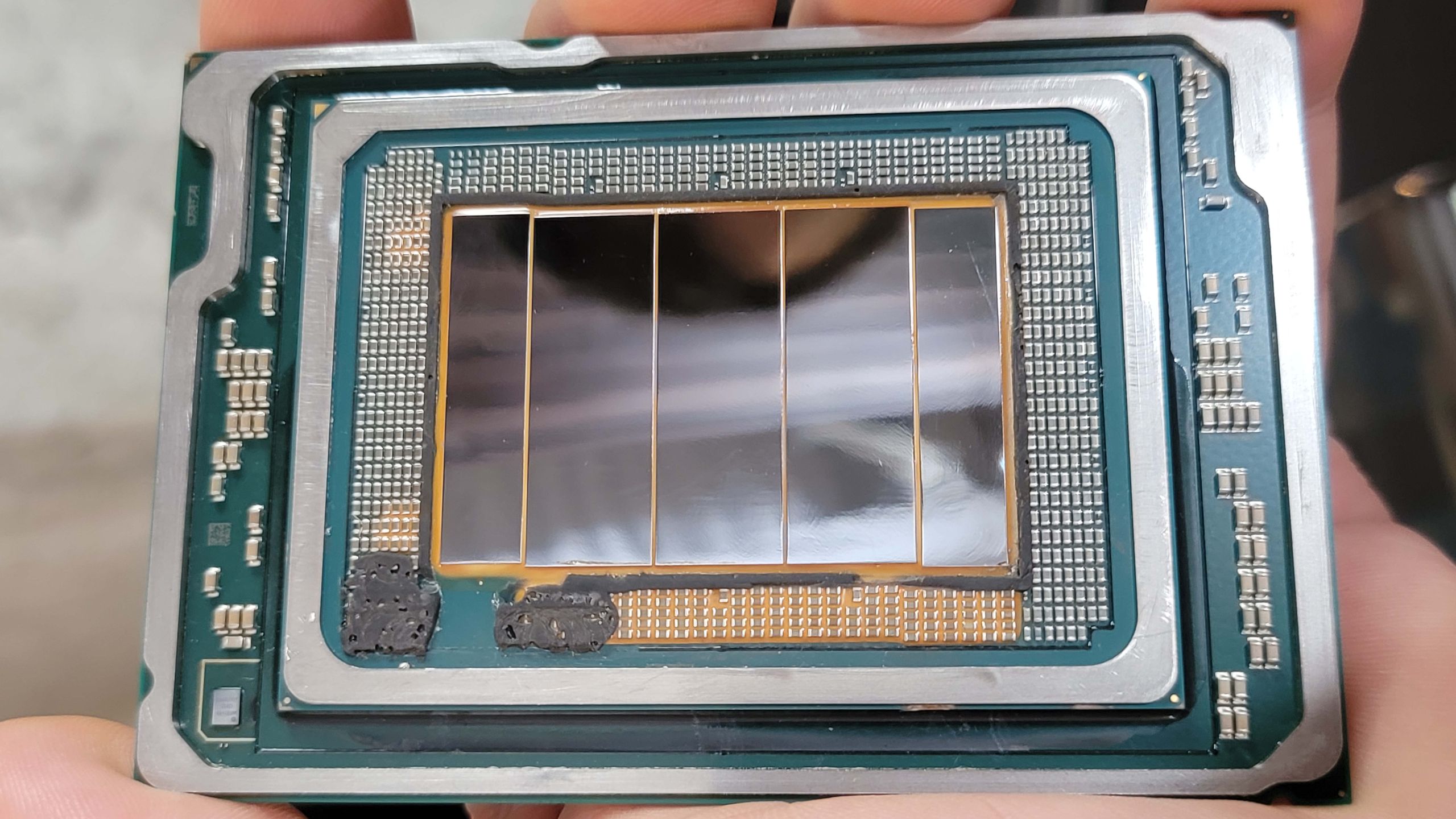

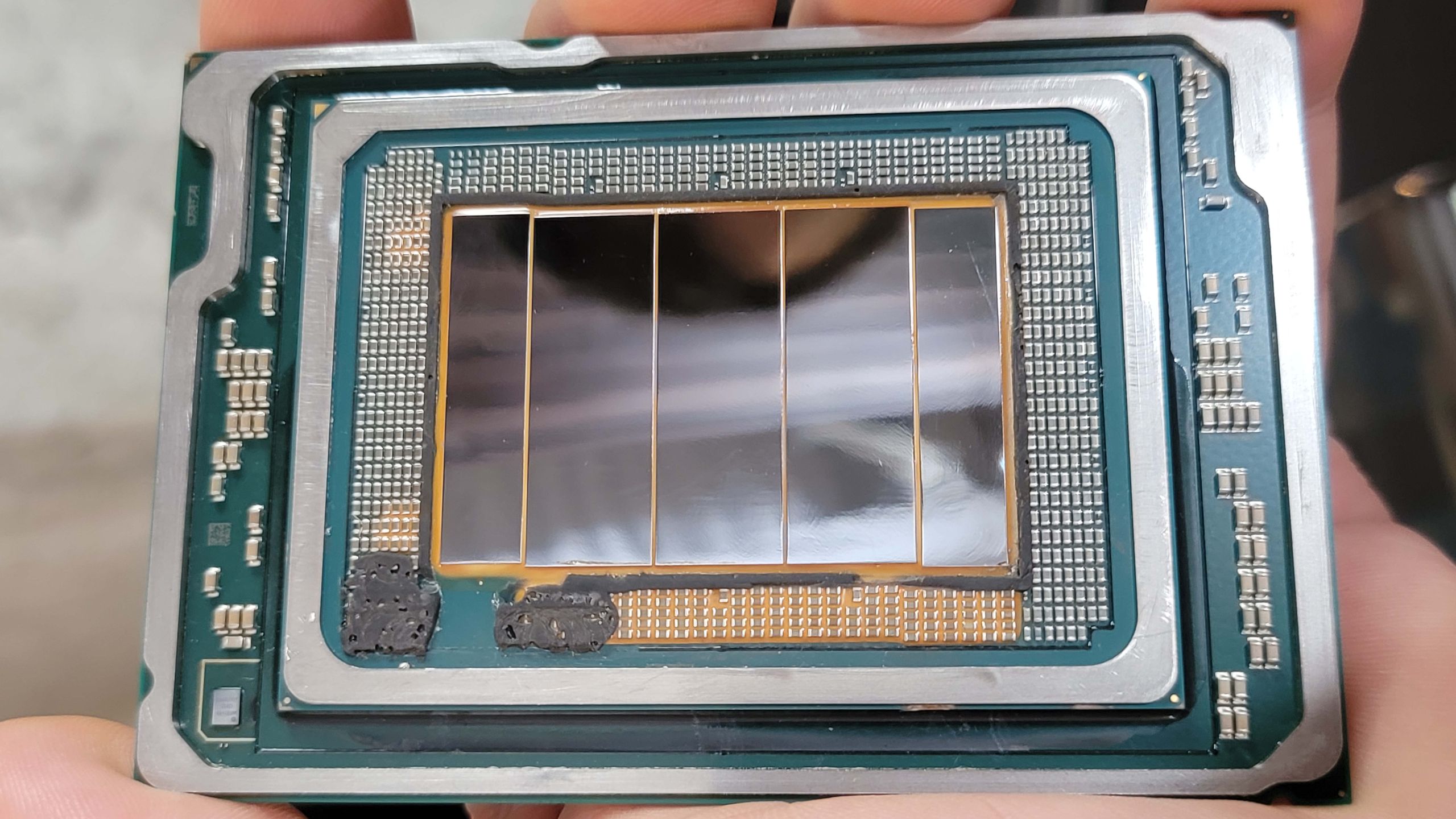

Forget Lunar Lake; If there's one chip family that serves as a lynchpin for Intel’s entire turnaround plan, it's this – the company’s coming Clearwater Forest Xeon that it revealed for the first time at a recent event. The chip family is exceedingly important because this is the first high-volume chip to be fabbed on the Intel 18A process node, a node so critical that Intel CEO Pat Gelsinger has said he has bet the entire company on it.

Yes, Intel will make plenty of other processors with the 18A node, but mass-producing the Clearwater Forest chips on time is paramount to building confidence in Intel Foundry for potential customers, and that's the key to Gelsinger's entire turnaround plan. It also marks the culmination of Gelsinger’s audacious and now seemingly last-ditch effort to develop five nodes in four years to spark a resurgence at the ailing chipmaker.

www.tomshardware.com

www.tomshardware.com

Yes, Intel will make plenty of other processors with the 18A node, but mass-producing the Clearwater Forest chips on time is paramount to building confidence in Intel Foundry for potential customers, and that's the key to Gelsinger's entire turnaround plan. It also marks the culmination of Gelsinger’s audacious and now seemingly last-ditch effort to develop five nodes in four years to spark a resurgence at the ailing chipmaker.

Intel’s entire turnaround plan hinges on this one new chip family – Clearwater Forest pictured, Intel’s first 18A chip slated for high-volume manufacturing

Clearwater Forest is key to Intel’s future.