jms_embedded

Well-known member

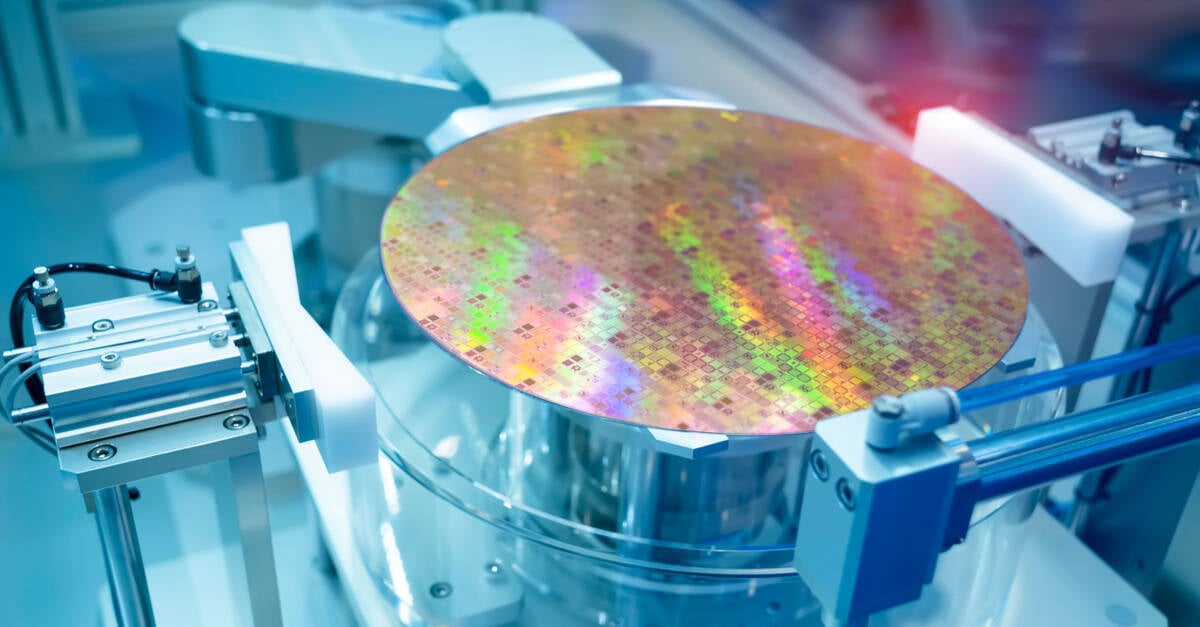

Amid a chip supply crunch, 28nm may end up underused

Put your nodes to the grindstone

Yes, it's The Register, but the reporters have gathered some interesting points from recent earnings calls.

Array

(

[content] =>

[params] => Array

(

[0] => /forum/threads/dear-chip-designers-if-youre-struggling-to-get-components-made-try-28nm-supply-set-to-overtake-demand-the-register.15484/

)

[addOns] => Array

(

[DL6/MLTP] => 13

[Hampel/TimeZoneDebug] => 1000070

[SV/ChangePostDate] => 2010200

[SemiWiki/Newsletter] => 1000010

[SemiWiki/WPMenu] => 1000010

[SemiWiki/XPressExtend] => 1000010

[ThemeHouse/XLink] => 1000970

[ThemeHouse/XPress] => 1010570

[XF] => 2030970

[XFI] => 1060170

)

[wordpress] => /var/www/html

)

From this Register's article, I found another interesting earnings conference call from Silicon Motion Technology. It discussed the market trend, TSMC capacity they are getting, and future growth.

Amid a chip supply crunch, 28nm may end up underused

Put your nodes to the grindstonewww.theregister.com

Yes, it's The Register, but the reporters have gathered some interesting points from recent earnings calls.

Nothing below 40nm is really friendly to what car industry uses.

Not there yet? or is there an inherent limitation to smaller geometry processes?High temperature silicon is also not there,

UMC 28nm is an immersion node. Not an outsourcing shop level design effort. You will spend way more than $1m on getting physical IP redesigned, and other NREs. Not to mention state of eFLASH on 28nm (all proprietary offers,) is not bright, and SRAM on 28nm is too expensive per area.

Nothing below 40nm is really friendly to what car industry uses. You can't use 28nm for high voltage analog, and pretty much anything else analog. SRAM/flash issue. RF IP is increasingly important because of demand for WiFi in MCUs is also not there. High temperature silicon is also not there, which means just anything 28nm will fail car certification in a lot of countries (even doorknob LED blinker often needs the same level of certification as the engine ECU chip.)

Then why did TSMC spend so much time and money on making their processes auto friendly?

Automotive Electronics Platform - Taiwan Semiconductor Manufacturing Company Limited

These are exciting times as we witness a transportation evolution. Pundits predict that on-demand ride sharing will replace car ownership substantially. Hybrid and electrical vehicles are growing in popularity in response to environmental regulations and governmental policy.www.tsmc.com

- NVM technologies for next generation MCU and AI memory