April 16, 2025

Plano, Texas, USA

Microsoft has published a story about the collaboration with Siemens and HARTING

Finding the right fit

Finding the right product among more than 27,000 options can feel like searching for a specific grain of sand on the beach. For customers juggling tight deadlines and complex technical needs, this task is often frustrating and time-consuming.

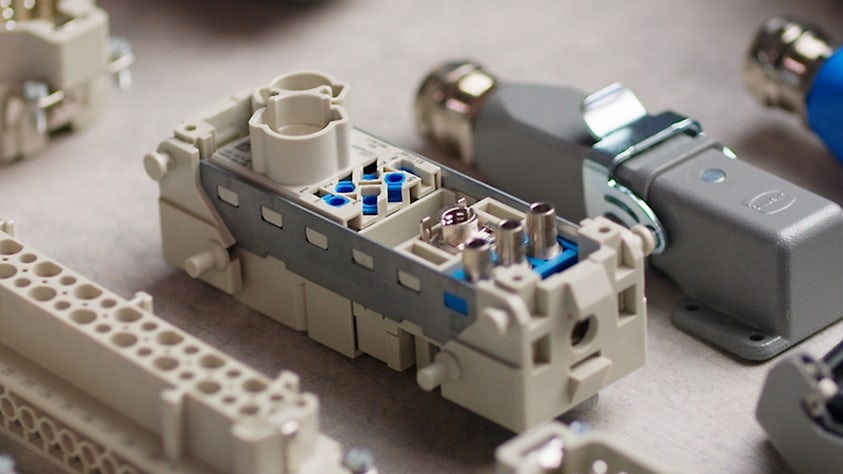

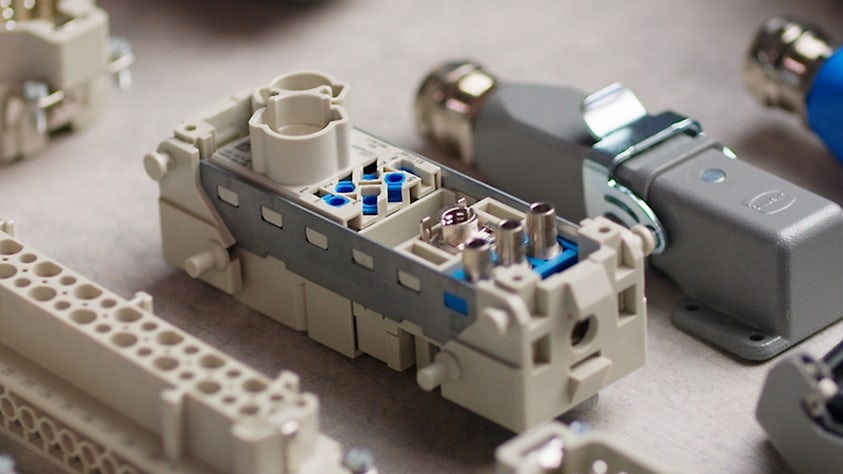

HARTING, a leader in industrial connectors, has been at the forefront of innovation for decades. “We have been creating connectors for 80 years, and we are always interested in what’s next,” says Norbert Gemmeke, Managing Director of HARTING, Business Unit Electric. HARTING products power everything from electric vehicle charging stations to datacenters, but traditional design and configuration processes were ripe for disruption.

“Our customers are not connectivity experts. They don’t use connectivity every day, so they don’t have the vocabulary,” explains Andreas Wedel, Director of Digital Transformation at HARTING Technology Group. This knowledge gap often caused delays, leaving HARTING searching for a solution.

Image courtesy of HARTING

Redefining possibilities with AI

HARTING’s transformation is about more than just speeding up processes—it’s about innovation. A new suite of tools makes designing connectors faster, easier, and more intuitive than ever.

“We needed an easier way for customers to find and design the product to fit their requirements,” Wedel explains.

HARTING’s AI-guided Han® Configurator, fueled by Microsoft Azure OpenAI Service and Microsoft Cloud for Manufacturing, lets customers describe their needs in natural language. AI translates these inputs into technical specifications, guiding them to the right product in just one minute. Customers can also visualize their configurations in 3D, building confidence in their decisions.

When an existing connector doesn’t meet requirements, HARTING’s engineers use a companion tool that was developed by HARTING’s Innovation Hub and interoperates with Siemens' NX and Simcenter, part of the Siemens Xcelerator portfolio, to create custom prototypes in minutes instead of weeks. Engineers can focus on complex tasks and research, while repetitive work is automated.

The AI assistant supports engineers by refining 2D layouts, verifying details, generating 3D models with Siemens' NX, and doing basic thermal FEM simulations. This interoperability allows HARTING to deliver faster, smarter, and more intuitive solutions

“HARTING would never have trained our own large language model,” says Julia Froehlich, Director of Innovation Hub at HARTING Technology Group. “We were glad to see the Microsoft model fits our purpose without additional training. It has real-world knowledge and even some industry knowledge we didn’t expect. That’s one reason we love this project—it allows us to maintain our connector expertise, which is our competitive edge, without sharing proprietary knowledge.”

Collaborative breakthroughs and lasting impact

The results have been transformative. Configuration times have dropped from 15 to 20 minutes to just one minute, and prototypes that once took weeks now take minutes.

“Our salespeople are really shocked, in a positive way, with what is possible. There is more than acceptance. They want to have this,” says Gemmeke.

Simon Hagen, Senior Innovation Engineer at HARTING Technology Group, credits teamwork as the key to success, explaining, “Each company brought unique knowledge to the table, and by working together with Siemens and Microsoft, we could build the modular architecture that made this project a reality.”

HARTING’s innovations set a new benchmark for customer-centric product development. These tools empower engineers, customers, and sales teams to work faster, smarter, and with greater confidence, transforming how connectors are designed and delivered.

Looking ahead

As innovation speeds up, HARTING is ready to lead. “Having the right partners is crucial, and Microsoft is one of them. Together with Siemens, it’s perfect,” says Gemmeke.

HARTING’s commitment to collaboration and excellence positions it to stay ahead in an ever-evolving industry. “We are convinced that development cycles will continue to shorten. AI is a big step forward in achieving that,” concludes Gemmeke.

To read the full story, visit the Microsoft Customer Story page.

Link to Press Release

Plano, Texas, USA

Microsoft has published a story about the collaboration with Siemens and HARTING

Finding the right fit

Finding the right product among more than 27,000 options can feel like searching for a specific grain of sand on the beach. For customers juggling tight deadlines and complex technical needs, this task is often frustrating and time-consuming.

HARTING, a leader in industrial connectors, has been at the forefront of innovation for decades. “We have been creating connectors for 80 years, and we are always interested in what’s next,” says Norbert Gemmeke, Managing Director of HARTING, Business Unit Electric. HARTING products power everything from electric vehicle charging stations to datacenters, but traditional design and configuration processes were ripe for disruption.

“Our customers are not connectivity experts. They don’t use connectivity every day, so they don’t have the vocabulary,” explains Andreas Wedel, Director of Digital Transformation at HARTING Technology Group. This knowledge gap often caused delays, leaving HARTING searching for a solution.

Image courtesy of HARTING

Redefining possibilities with AI

HARTING’s transformation is about more than just speeding up processes—it’s about innovation. A new suite of tools makes designing connectors faster, easier, and more intuitive than ever.

“We needed an easier way for customers to find and design the product to fit their requirements,” Wedel explains.

HARTING’s AI-guided Han® Configurator, fueled by Microsoft Azure OpenAI Service and Microsoft Cloud for Manufacturing, lets customers describe their needs in natural language. AI translates these inputs into technical specifications, guiding them to the right product in just one minute. Customers can also visualize their configurations in 3D, building confidence in their decisions.

When an existing connector doesn’t meet requirements, HARTING’s engineers use a companion tool that was developed by HARTING’s Innovation Hub and interoperates with Siemens' NX and Simcenter, part of the Siemens Xcelerator portfolio, to create custom prototypes in minutes instead of weeks. Engineers can focus on complex tasks and research, while repetitive work is automated.

The AI assistant supports engineers by refining 2D layouts, verifying details, generating 3D models with Siemens' NX, and doing basic thermal FEM simulations. This interoperability allows HARTING to deliver faster, smarter, and more intuitive solutions

“HARTING would never have trained our own large language model,” says Julia Froehlich, Director of Innovation Hub at HARTING Technology Group. “We were glad to see the Microsoft model fits our purpose without additional training. It has real-world knowledge and even some industry knowledge we didn’t expect. That’s one reason we love this project—it allows us to maintain our connector expertise, which is our competitive edge, without sharing proprietary knowledge.”

Collaborative breakthroughs and lasting impact

The results have been transformative. Configuration times have dropped from 15 to 20 minutes to just one minute, and prototypes that once took weeks now take minutes.

“Our salespeople are really shocked, in a positive way, with what is possible. There is more than acceptance. They want to have this,” says Gemmeke.

Simon Hagen, Senior Innovation Engineer at HARTING Technology Group, credits teamwork as the key to success, explaining, “Each company brought unique knowledge to the table, and by working together with Siemens and Microsoft, we could build the modular architecture that made this project a reality.”

HARTING’s innovations set a new benchmark for customer-centric product development. These tools empower engineers, customers, and sales teams to work faster, smarter, and with greater confidence, transforming how connectors are designed and delivered.

Looking ahead

As innovation speeds up, HARTING is ready to lead. “Having the right partners is crucial, and Microsoft is one of them. Together with Siemens, it’s perfect,” says Gemmeke.

HARTING’s commitment to collaboration and excellence positions it to stay ahead in an ever-evolving industry. “We are convinced that development cycles will continue to shorten. AI is a big step forward in achieving that,” concludes Gemmeke.

To read the full story, visit the Microsoft Customer Story page.

Link to Press Release