Accelerating investment in the US, 30% of future 2nm and higher-level processes will be located in the US, and the difficulties of setting up factories will be transformed into the fruits of success.

TSMC has made early deployments and accelerated its investment in the United States, investing $165 billion in Arizona to build a semiconductor ecosystem. (Photo provided by TSMC)

The United States has announced a 20% reciprocal tariff rate for Taiwan. IC design companies point out that these tariffs will raise costs, potentially indirectly impacting the supply chain. However, the semiconductor tariffs will have a greater impact on the chips themselves, and the rate will depend on the outcome of the US Section 232 investigation. As for upstream wafer fabrication companies, TSMC has already established its presence and is increasing and accelerating investment in the US. It will provide domestic chip production capacity in accordance with customer requirements. Past efforts will ultimately yield fruitful results.

Taiwan's reciprocal tariff is higher than the 15% of its main competitors, Japan and South Korea. In any case, the situation has been settled for high-tech companies. Once the tax rates of the main component producing countries are confirmed, resources can be reallocated.

IC design industry analysts believe that tariffs may indeed put pressure on the supply chain and affect IC profit margins, but in terms of reciprocal tariffs, the direct impact on ICs is small. In addition to price factors, the indirect impact is also the sluggish end-user demand, which is the industry's biggest concern.

Future semiconductor tariffs will directly impact semiconductor operations, but the results of the Section 232 investigation remain, and it's too early to accurately assess the potential impact. IC design companies will work closely with their foundry partners. Industry insiders reveal that production bases are paramount, which is why leading foundry companies are establishing factories in the United States in response to customer demand.

TSMC Chairman Wei Zhejia once described the difficulties of setting up a US factory with tears and snot. But now, facing high tariffs, Wei, who controls domestic production capacity, is likely to smile. This is because TSMC is already preparing production capacity in the US, and 30% of its future 2nm and higher process technology will be located there.

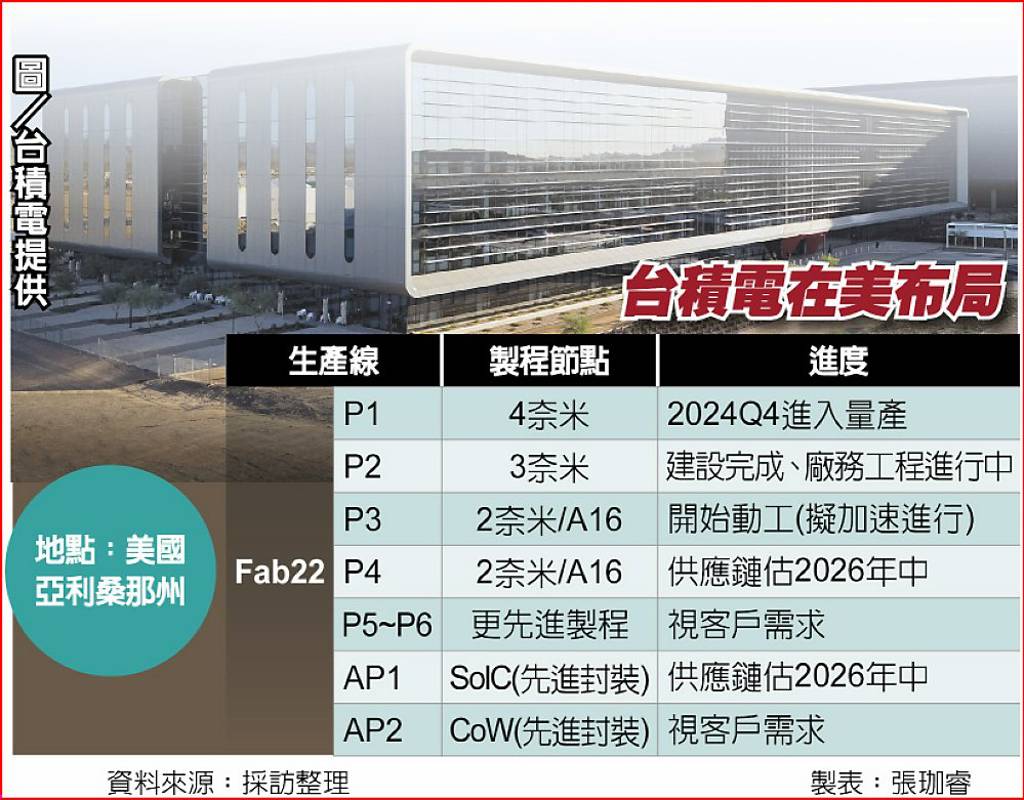

TSMC will invest $165 billion in Arizona to build a semiconductor ecosystem. Plans include six wafer foundries, two advanced packaging facilities, and a research and development center. Currently, the P1 facility has entered mass production, the P2 facility is complete, and construction on the P3 facility is underway at an accelerated pace. A factory operator stated that a team has already moved into the P2 facility, and the selection process for the P3 facility will be open for bidding.

TSMC's layout in the United States

The supply chain revealed that the advanced packaging plant and P4 are expected to begin construction in the middle of next year. Chip industry insiders said that American manufacturing will become a popular trend, including advanced packaging, and TSMC's CoW production capacity will also be available locally in the future.

Supply chain analysis shows that TSMC is currently the only company capable of large-scale and stable mass production of advanced process chips. It has formed an oligopoly in this field and can moderately reflect value. Ultimately, chip manufacturers such as Nvidia, Apple, and AMD will be affected. Trump wants chips to be manufactured in the United States, and it seems that his goal has been achieved, but this is tantamount to weakening the importance of Taiwan's chip production.