Wow. This story is evoking a lot of responses. it may be your most popular article ever, Dan. BTW: I agree. Tough to run a good Fab working from home.It's going to get worse. Americans now want to work from home all or part time, not punch a manufacturing clock each morning and afternoon.

Array

(

[content] =>

[params] => Array

(

[0] => /forum/threads/tsmc-founder-doubts-us-competence-in-chip-making.14276/page-2

)

[addOns] => Array

(

[DL6/MLTP] => 13

[Hampel/TimeZoneDebug] => 1000070

[SV/ChangePostDate] => 2010200

[SemiWiki/Newsletter] => 1000010

[SemiWiki/WPMenu] => 1000010

[SemiWiki/XPressExtend] => 1000010

[ThemeHouse/XLink] => 1000970

[ThemeHouse/XPress] => 1010570

[XF] => 2021770

[XFI] => 1050270

)

[wordpress] => /var/www/html

)

Guests have limited access.

Join our community today!

Join our community today!

You are currently viewing SemiWiki as a guest which gives you limited access to the site. To view blog comments and experience other SemiWiki features you must be a registered member. Registration is fast, simple, and absolutely free so please, join our community today!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TSMC founder doubts US competence in chip-making

- Thread starter Daniel Nenni

- Start date

Sorry, it’s not hard and I and more than half the engineers in my department did it for 11 months. This probably suprises many people I respect on this board so I’ll go into some detail.Wow. This story is evoking a lot of responses. it may be your most popular article ever, Dan. BTW: I agree. Tough to run a good Fab working from home.

Modern fabs are highly, highly, highly automated with about 2 people for every robot. At one time fabs were close to being “lights out” in the sense lots could run from end to end without human intervention. Fabs are basically capable of turning the lights out today, but quality standards have leapt and continue to increase, so intervention is necessary, to tweak slightly. That is the context in which aggressive WFH occurred.

Fabs did not want WFH because of the model of constant tweaking. But quality standards, as it turned out, were maintained. More than that, quality standards improved; everything got better. Because less tweaking creates a more stable process. This was a big lesson learned, although it is being denied and buried. Then the chip shortage happened and about the same time, Texas fabs had about 2 months worth of production knocked out by 4 days of power interruption.

The response to the chip shortage has been to expand production. This is one area where it is “Tough to run a good fab working from home”. Installing a tool is completely unautomated, and it has created unprecedented demand for contractors. These individuals are plumbers, electricians; basically a different category of fab employee, but very essential. They were never WFH.

WFH fabs had better quality, because engineers were forced to sit on their hands. Expansion has reversed WFH and quality is worse. There is a lot of press about the benefits of work from home, and some of it is clickbait and propaganda, but what I’ve seen myself is that WFH is an improvement and a win-win-win for advanced fabs.

Wow. Interesting!! I stand corrected.Sorry, it’s not hard and I and more than half the engineers in my department did it for 11 months. This probably suprises many people I respect on this board so I’ll go into some detail.

Modern fabs are highly, highly, highly automated with about 2 people for every robot. At one time fabs were close to being “lights out” in the sense lots could run from end to end without human intervention. Fabs are basically capable of turning the lights out today, but quality standards have leapt and continue to increase, so intervention is necessary, to tweak slightly. That is the context in which aggressive WFH occurred.

Fabs did not want WFH because of the model of constant tweaking. But quality standards, as it turned out, were maintained. More than that, quality standards improved; everything got better. Because less tweaking creates a more stable process. This was a big lesson learned, although it is being denied and buried. Then the chip shortage happened and about the same time, Texas fabs had about 2 months worth of production knocked out by 4 days of power interruption.

The response to the chip shortage has been to expand production. This is one area where it is “Tough to run a good fab working from home”. Installing a tool is completely unautomated, and it has created unprecedented demand for contractors. These individuals are plumbers, electricians; basically a different category of fab employee, but very essential. They were never WFH.

WFH fabs had better quality, because engineers were forced to sit on their hands. Expansion has reversed WFH and quality is worse. There is a lot of press about the benefits of work from home, and some of it is clickbait and propaganda, but what I’ve seen myself is that WFH is an improvement and a win-win-win for advanced fabs.

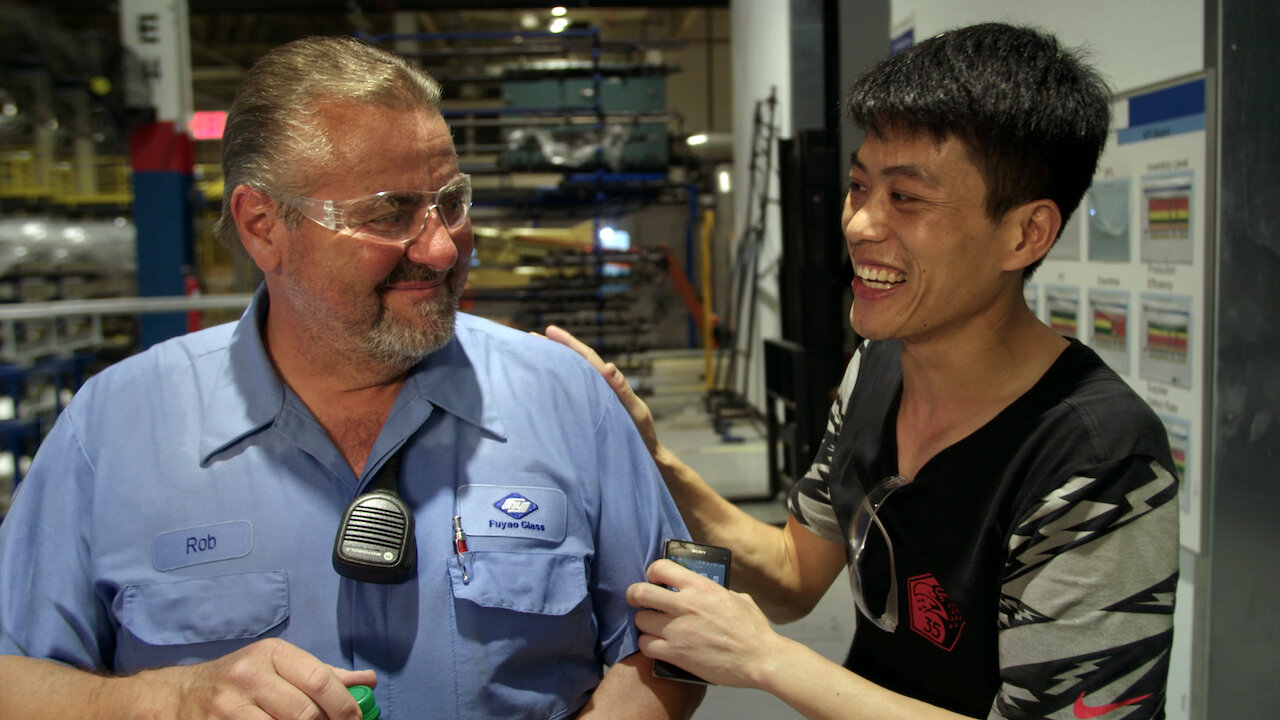

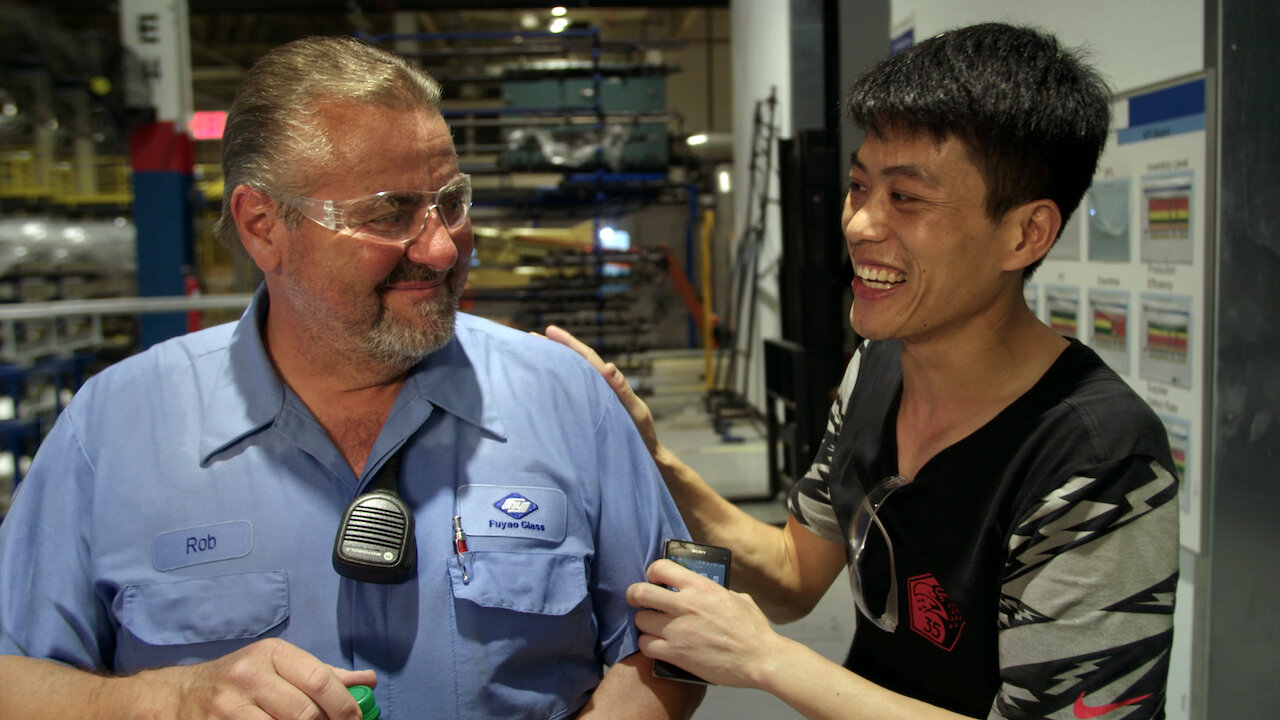

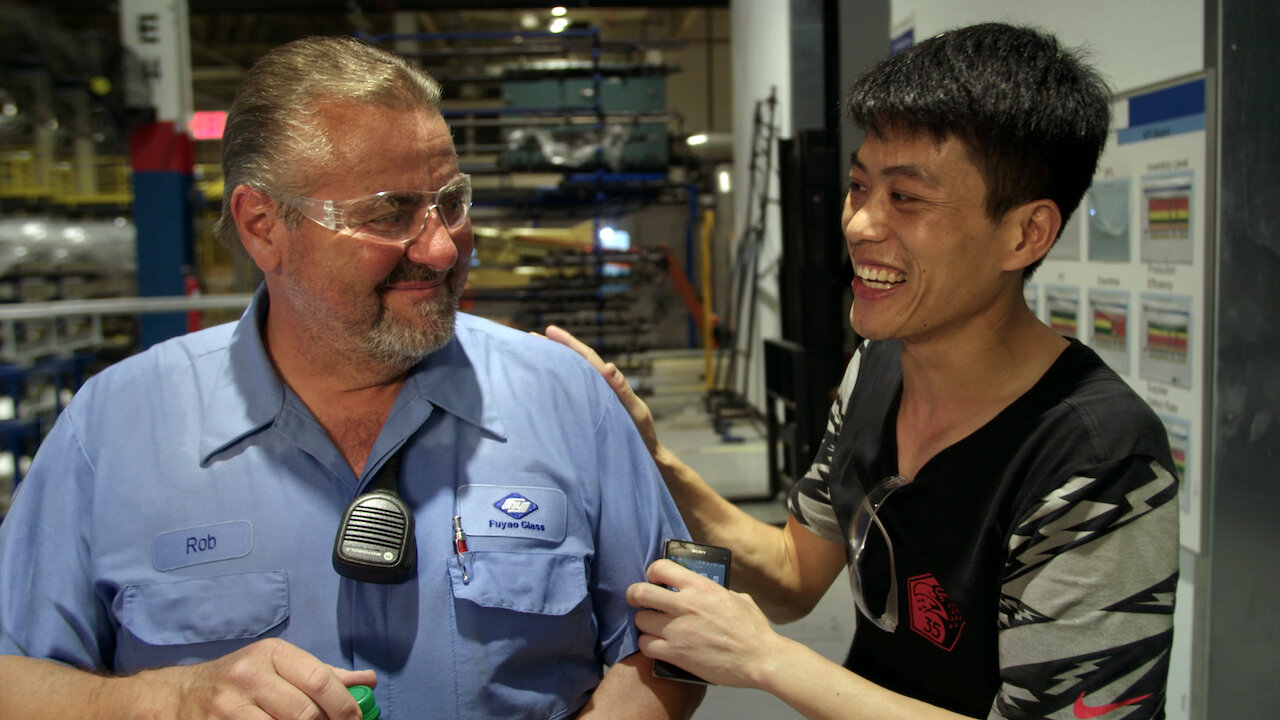

To anyone interested in the topic, who didn't see the documentary "American Factory" yet:

Watch it, it's really worth your time!

Also about semiconductors by the way, ahum; but a different kind than discussed on Semiwiki.

www.netflix.com

www.netflix.com

Apart from the labour union scenes and absurd rules, the US could easily be exchanged for Europe in this movie; and maybe China also for Taiwan?

Watch it, it's really worth your time!

Also about semiconductors by the way, ahum; but a different kind than discussed on Semiwiki.

Watch American Factory | Netflix Official Site

In this documentary, hopes soar when a Chinese company reopens a shuttered factory in Ohio. But a culture clash threatens to shatter an American dream.

Apart from the labour union scenes and absurd rules, the US could easily be exchanged for Europe in this movie; and maybe China also for Taiwan?

I watched this some time ago, and I think it's a great movie that highlights the cultural divide between the US and China and really shows why it's difficult for the US to compete in manufacturing.To anyone interested in the topic, who didn't see the documentary "American Factory" yet:

Watch it, it's really worth your time!

Also about semiconductors by the way, ahum; but a different kind than discussed on Semiwiki.

Watch American Factory | Netflix Official Site

In this documentary, hopes soar when a Chinese company reopens a shuttered factory in Ohio. But a culture clash threatens to shatter an American dream.www.netflix.com

Apart from the labour union scenes and absurd rules, the US could easily be exchanged for Europe in this movie; and maybe China also for Taiwan?

I think China will almost inevitably rise to being a semiconductor manufacturing powerhouse, but it will take some time. My guess is it won't happen until after scaling limits are hit and the industry slows down enough for the Chinese industry to catch up.

It really depends on one thing only:

Whether it will keep remaining the biggest semi market, or not.

Currently it is, and so far extracts very, very little gain from that. It's almost inexplicable how much money is thrown on semis there, and how little that changes.

There were very very few successful companies on memory:

- Allwinner — had a double digit in SoC market share at around 65/40nm era, but lost spectacularly once they got in bed with Qualcomm (Their execs though will forget about what a need is for the next few lifetimes)

- Rockchips — had a double digit in SoC market share at around 65/40nm era, but lost spectacularly once they got in bed with Intel (Their execs though will forget about what a need is for the next few lifetimes)

- Gigadevices — so far doing very good focusing on low end MCU, and memory. The current MCU crunch quadrupled their cash stash.

- CanSemi — so far doing very good focusing on low end MCU, and memory. The current MCU crunch tripled their cash stash.

Last edited:

jeffwessel

New member

Asia Times Article - Neither Trump, Biden or anyone else told the car companies to cancel chip orders. This IMO was caused by their short term follow the crowd management philosophy. Toyota seems to have been the only company who understood much of risk of cancelling semiconductor orders. The media and the politicians have whipped this into a bigger frenzy than it is. I should also say that its the laggards in the industry who seem to want to feed at the government trough.

Morris Chang's comments - History will reply whether or not his criticism was too strong on the USA. There are many changes that need to be made here. Our education system and current culture turn out people whose goals have nothing to do with advancing society. Paying people not to work is another one of them. Not being able to live within our means is another. If anyone believes that the US will ever pay back its national debt is delusional. On that matter, interest rates cannot go up because if they do the US will be in default for not being able to pay the interest.

Long live people like Morris Chang who have improved this world from where it was when he entered it. If he is a little overly critical, get over it and learn what you can from it.

Morris Chang's comments - History will reply whether or not his criticism was too strong on the USA. There are many changes that need to be made here. Our education system and current culture turn out people whose goals have nothing to do with advancing society. Paying people not to work is another one of them. Not being able to live within our means is another. If anyone believes that the US will ever pay back its national debt is delusional. On that matter, interest rates cannot go up because if they do the US will be in default for not being able to pay the interest.

Long live people like Morris Chang who have improved this world from where it was when he entered it. If he is a little overly critical, get over it and learn what you can from it.