Samsung is reportedly mulling to update its fabrication capabilities in the Taylor fab near Austin from 4nm to 2nm, and delaying the related equipment orders, according to reports from Tom’s Hardware and Korea media outlet ETnews. The decision is said to be made in Q3 2024.

Samsung’s initial projection, announced in 2021 when the investment plan was disclosed, had anticipated the Taylor plant to start its mass production of 4nm in the second half of 2024. But afterwards, the tech giant has reportedly postponed the schedule to 2025.

Now, according to the latest reports, with the AI hardware race intensifying and Nvidia, one of Samsung’s biggest clients, keeps advancing in its GPU platforms, 4nm production may no longer suffice. Therefore, Samsung has postponed its equipment orders for the Taylor fab as it considers the upgrade from 4nm to 2nm. The plant may not begin operations until 2026, US local media MySA noted.

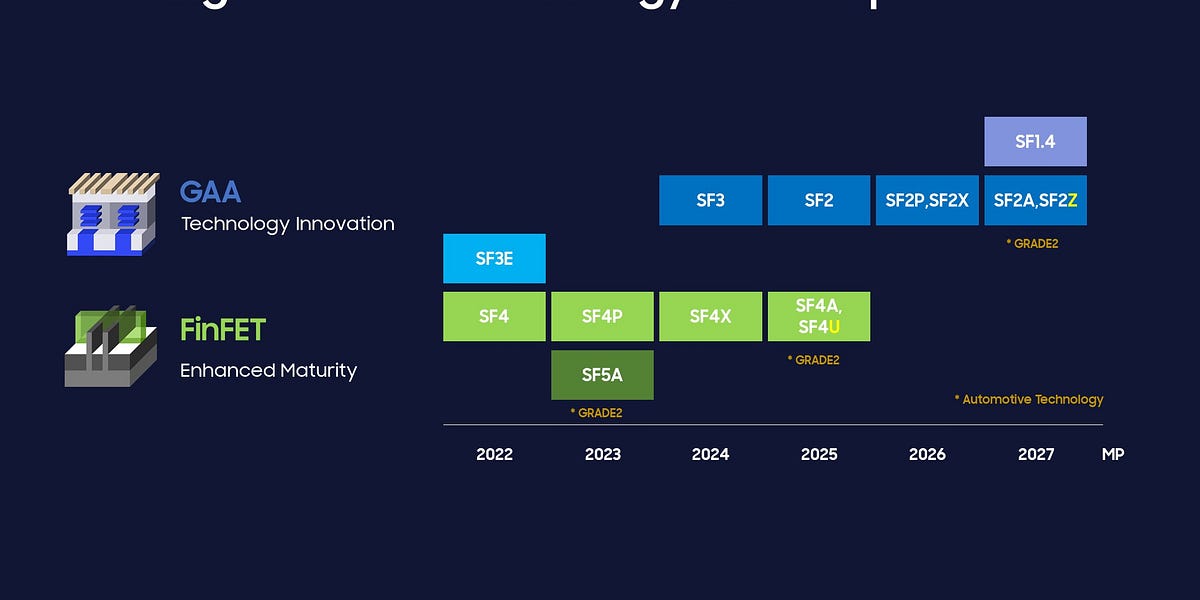

According to information from Samsung’s press release, the company plans to provide one-stop solution for clients to expedite their production of AI chips, while its updated 2nm node with backside power delivery is expected to enter the market in 2027. SF4U, its high-value 4nm variant that offers PPA improvements by incorporating optical shrink, plans to enter mass production in 2025.

Earlier in April, the U.S. government announced that it will provide up to USD 6.4 billion in subsidies to Samsung for expanding advanced chip production capacity at its Texas plant, while it previously approved subsidies of up to USD 8.5 billion for US chip giant Intel and USD 6.6 billion for TSMC, respectively.

Regarding major semiconductor companies’ capacity expansion plans in the U.S., TSMC’s new fab in Arizona aims to complete all preparations for mass production by the end of this year, and commences mass production using the 4-nanometer process in the first half of 2025. On the other hand, TSMC also plans to build a third fab in Arizona, which will use 2nm process or even more advanced technologies to manufacture wafers for customers, though the date for construction has yet to be disclosed.

Meanwhile, Intel plans to mass-produce its 20A and 18A nodes at its Arizona and Ohio plants in 2024 and 2025, respectively.

[News] Samsung Reportedly Delays Its Texas Fab, Mulling Upgrade from 4nm to 2nm | TrendForce News

Samsung is reportedly mulling to update its fabrication capabilities in the Taylor fab near Austin from 4nm to 2nm, and delaying the related equipment...