fansink

Well-known member

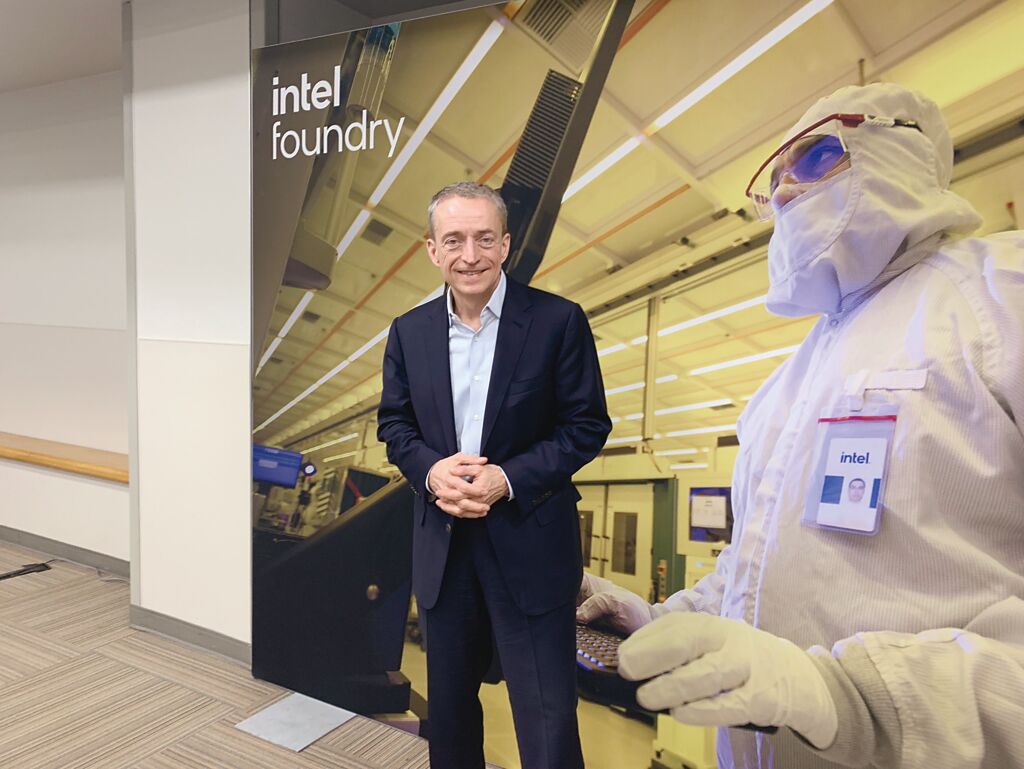

According to various articles (probably same source), TSMC will be producing Intel CPUs, GPUs, and NPUs tiles for the Arrow and Lunar Lake platforms.

Is this true?

Is this going to affect Nvidia's already strained chip supply?

www.trendforce.com

www.trendforce.com

wccftech.com

wccftech.com

Is this true?

Is this going to affect Nvidia's already strained chip supply?

[News] Gelsinger Opens Up, as Intel Reportedly Expands Orders to TSMC | TrendForce Insights

Pat Gelsinger, CEO of Intel, announced on February 22nd that Intel will expand its orders to TSMC, as per a report by Commercial Times. Following t...

Intel CEO Confirms TSMC's Process Nodes To Power Next-Gen CPUs: N3 For Arrow Lake & N3B For Lunar Lake

Intel CEO confirms the use of TSMC N3 process node for next-gen Arrow Lake & N3B node for its Lunar Lake CPUs launching later this year.