Arthur Hanson

Well-known member

Heat being the obstacle to driving high-performance semis, this new method of dealing with heat offers another method of increasing performance at what may be far better and lower cost than other methods. Any thoughts or comments on this would be appreciated.

newatlas.com

newatlas.com

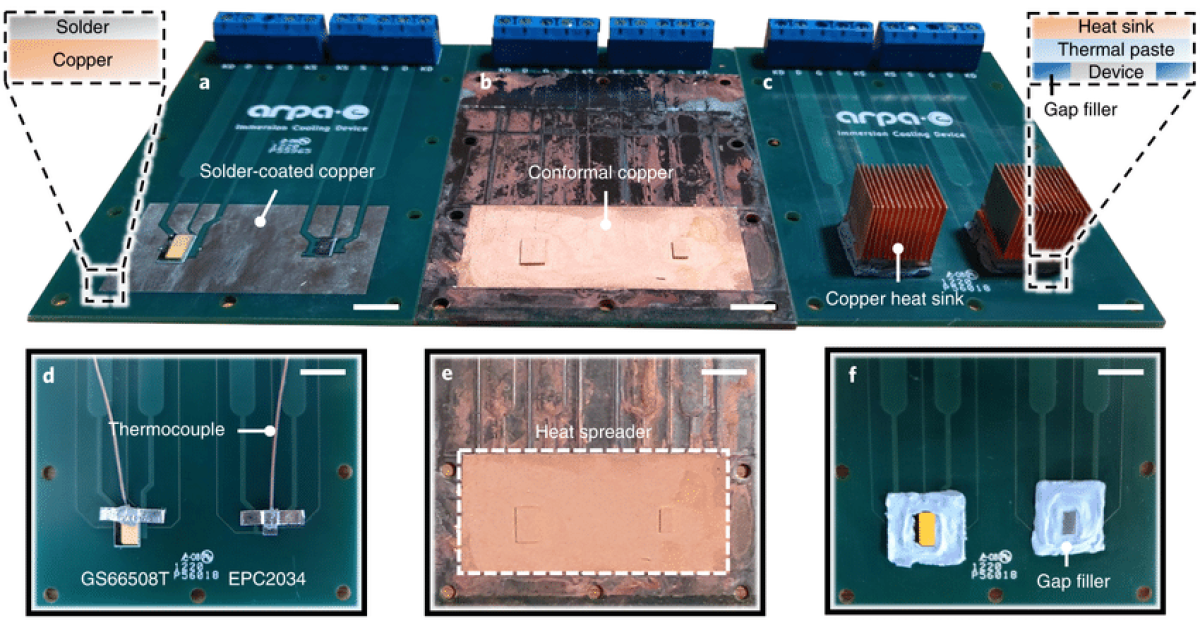

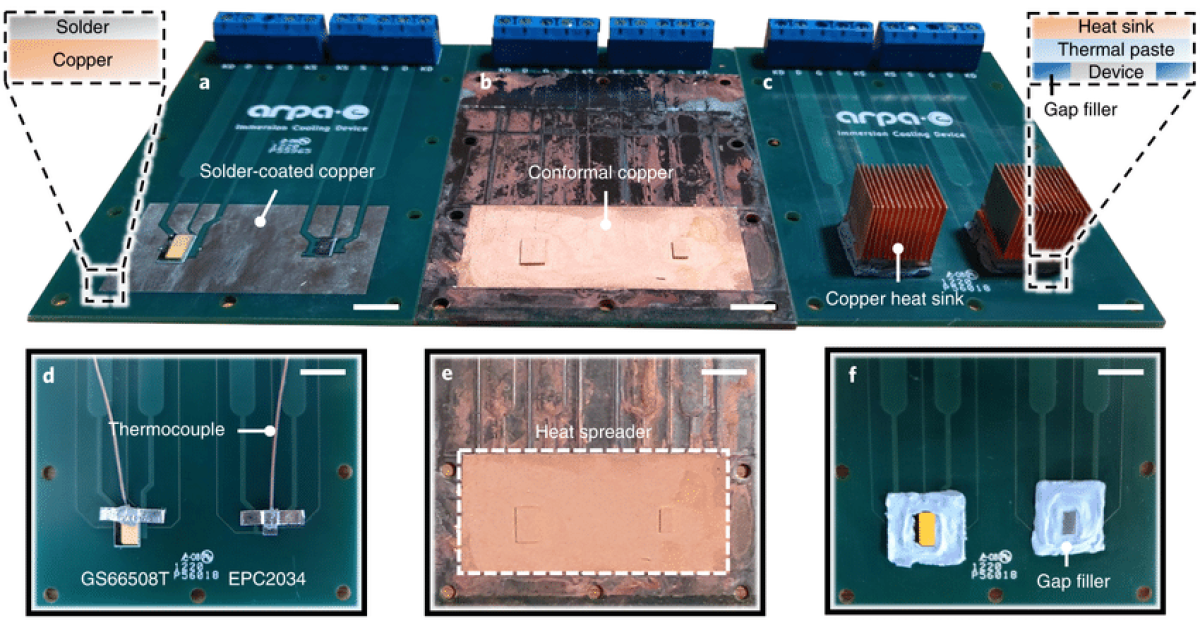

New heat spreading tech delivers 740% increase in circuit power density

A team from the University of Illinois and UC Berkeley has demonstrated a new cooling method that sucks heat out of electronics so efficiently that it allows designers to run 7.4 times more power through a given volume than conventional heat sinks.